News and articles from Topstar

We are committed to the innovation and application of industrial manufacturing automation.

-

2026/02/04 By: le zhan

The Importance of Auxiliary Equipment in Injection Molding Production

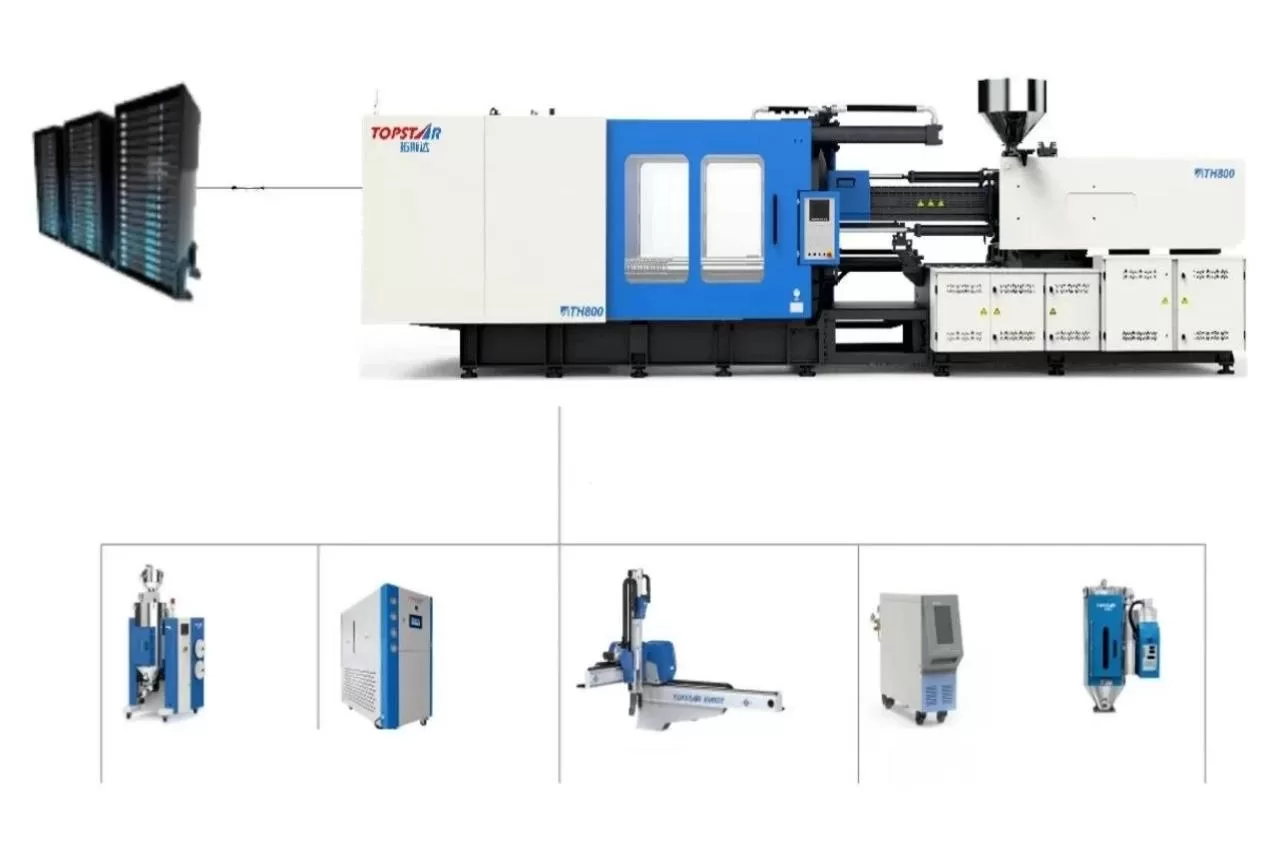

Auxiliary equipment transforms injection molding operations from a single-machine operation into a stable, repeatable production system. While the core task of the injection molding machine is to plasticize and inject molten material into the mold, injection molding auxiliary equipment controls material state, thermal stability, part handling, and process continuity. Without properly configured auxiliary systems, even… Continue reading The Importance of Auxiliary Equipment in Injection Molding Production

-

2026/02/02 By: le zhan

Why is the Topstar gravimetric blender the best choice for metering and mixing?

When you rely on expensive masterbatches or variable additives, even minor deviations in proportion can lead to economic losses and affect product performance. The Topstar gravimetric blender is designed to address these pain points effectively. As auxiliary equipment specifically designed for injection molding, the Topstar plastic gravimetric blender accurately meters and mixes two to six… Continue reading Why is the Topstar gravimetric blender the best choice for metering and mixing?

-

2026/01/28 By: le zhan

System compatibility: Topstar injection molding auxiliary equipment offers high integration for improved efficienc

In today’s injection molding production, efficiency no longer depends solely on the injection molding machine itself, but rather on the coordinated operation of the entire production system. From material handling and drying to temperature control and automation, injection molding auxiliary equipment plays a crucial role in determining productivity, product consistency, and operating costs. However, many… Continue reading System compatibility: Topstar injection molding auxiliary equipment offers high integration for improved efficienc

-

2026/01/26 By: le zhan

Why is your plastic dryer for injection molding not reaching the dew point?

The temperature has been precisely set, the injection volume optimized, and the cycle time configured, but the parts still exhibit problems such as splashing, bubbles, or inconsistent mechanical properties. Often, the common cause is moisture. If the plastic dryer for injection molding fails to reach the specified dew point, it cannot completely remove moisture from… Continue reading Why is your plastic dryer for injection molding not reaching the dew point?

-

2026/01/23 By: le zhan

Low speed 20~28 rpm: Topstar soundproof granulator achieves energy-saving and low-noise processing

Noise, dust, and energy waste are not just disruptions in the production process; they represent real costs. When high-speed granulators hum in plastic recycling or production workshops, businesses incur high electricity bills, worker fatigue, and additional cleanup. Topstar’s soundproof granulator, designed with a low-speed (20-28 rpm) cutting approach, effectively addresses this issue. Topstar combines low-speed… Continue reading Low speed 20~28 rpm: Topstar soundproof granulator achieves energy-saving and low-noise processing

-

2026/01/21 By: le zhan

How to choose the right auto loader to meet the material conveying needs of injection molding?

A suitable auto loader directly impacts the output, product quality, and uptime of an injection molding production line. An unsuitable feeder of the wrong size or specifications can lead to insufficient material supply, contamination, increased maintenance costs, and lost production time. A suitable auto loader seamlessly integrates into the production process, reliably delivering clean granules,… Continue reading How to choose the right auto loader to meet the material conveying needs of injection molding?

-

2026/01/19 By: le zhan

Controllable temperature range: Topstar mold temperature controller meet diverse needs

When stable and responsive, the part can be molded in a single cycle. Once temperature deviations occur, cycle time, part dimensions, and product yield are all affected. Topstar’s mold temperature controller combines a dedicated 7-inch touchscreen, an optimized PID algorithm that improves control efficiency by approximately 10%, and a fast-response solid-state relay with a switching… Continue reading Controllable temperature range: Topstar mold temperature controller meet diverse needs

-

2026/01/16 By: le zhan

Can Topstar Plastic Molding Machine Handle High-Temperature Plastics for Injection Molding?

Processing high-temperature plastics requires exceptional care, demanding precise heating, controlled shearing, and reliable thermal management; otherwise, both material performance and production efficiency will be compromised. As a professional injection molding machine manufacturer, we believe that a plastic molding machine must combine the correct screw metallurgy, precise temperature control, robust mechanical design, and safe and reliable… Continue reading Can Topstar Plastic Molding Machine Handle High-Temperature Plastics for Injection Molding?

-

2026/01/14 By: le zhan

6 major advantages of Topstar granulator machine in processing rigid plastics and brittle plastics

When customers talk about “difficult-to-process” plastics in injection molding, they refer to materials that tend to break, generate fine powder, and overheat during grinding—problems that lead to contamination and quality issues. The Topstar granulator machine is designed to address these pain points. With screenless grinding technology, low-speed gear-driven cutters, a rapid recycling process, and heavy-duty… Continue reading 6 major advantages of Topstar granulator machine in processing rigid plastics and brittle plastics

-

2026/01/12 By: le zhan

How can hopper dryers improve the quality and stability of plastic products?

Trace amounts of moisture in plastic material granules can lead to surface defects, insufficient weld line strength, and inconsistent dimensions. Hopper dryers address this problem by removing moisture before molding, but not all perform equally well. The right dryer design, control logic, and installation can directly improve the quality and consistency of plastic products. Therefore,… Continue reading How can hopper dryers improve the quality and stability of plastic products?

-

2026/01/08 By: le zhan

How to achieve precise temperature control in the 5-35℃ range on a water chiller?

Precise temperature control is the key to high-quality plastic products. When the cooling system can accurately control the water temperature within the set range, manufacturers can reduce defects, achieve better surface finish, and maintain more stable production cycles. Achieving this reliability doesn’t rely solely on a single component, but rather on the integrated use of… Continue reading How to achieve precise temperature control in the 5-35℃ range on a water chiller?

-

2026/01/06 By: le zhan

Is it possible to achieve ultra-long stroke mold opening on a plastic injection molding machine?

When you need to injection mold a large, multi-part automotive housing, or a deep, multi-cavity cosmetic container, the two halves of the mold need to move an exceptionally long distance to clear complex cores, inserts, or multi-stage ejection systems. On traditional plastic injection molding machines, you either accept limited mold geometries or purchase larger, slower… Continue reading Is it possible to achieve ultra-long stroke mold opening on a plastic injection molding machine?