News and articles from Topstar

We are committed to the innovation and application of industrial manufacturing automation.

-

2025/07/09 By: Topstar

How to prevent short cycling of the water chiller compressor?

Water chillers that operate with injection molding machines must maintain a stable temperature and avoid unnecessary short cycling of the compressors to ensure optimal performance. Short cycling (i.e., frequent on and off of the compressor) shortens compressor life, increases energy consumption, and can cause system failures. We will examine how water chiller design can address… Continue reading How to prevent short cycling of the water chiller compressor?

-

2025/07/07 By: Topstar

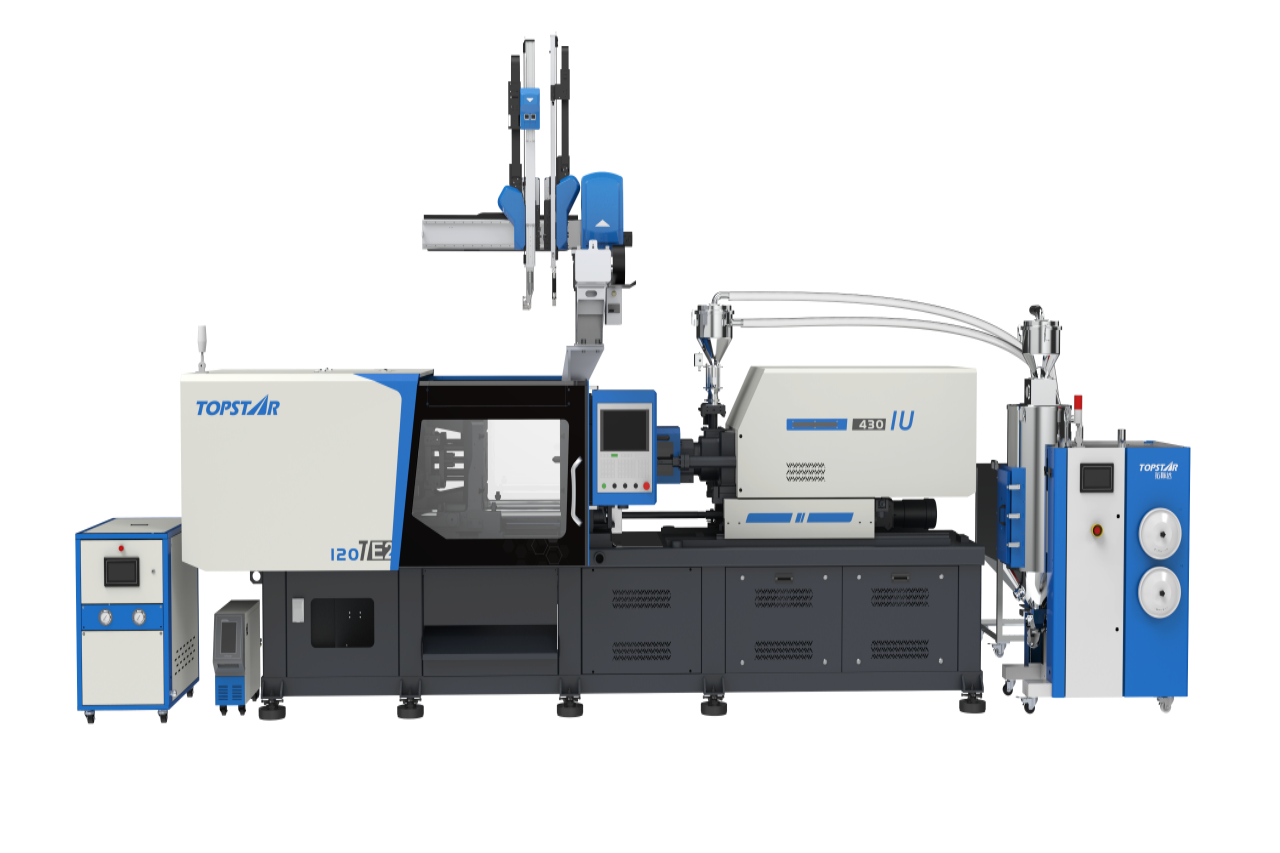

What auxiliary equipment does a large injection molding machine need?

A standalone injection molding machine cannot operate optimally without a complete set of auxiliary equipment to handle material conditioning, temperature control, and waste management, which are critical to a stable and productive molding cycle. Generally speaking, seven key auxiliary equipment are required for each large injection molding machine installation, including mold temperature controllers, chillers, material… Continue reading What auxiliary equipment does a large injection molding machine need?

-

2025/07/04 By: Topstar

How to adjust the velocity profile of a 3-axis robot to avoid vibration?

Designed for precision injection molding applications, 3-axis robots are designed explicitly for pick-and-place operations. If slight vibrations during part removal can affect quality, increase cycle time, and cause unplanned maintenance. Therefore, we integrate vibration suppression functions throughout the mechanical design and control firmware of the 3-axis robot, while also considering how to adjust the speed… Continue reading How to adjust the velocity profile of a 3-axis robot to avoid vibration?

-

2025/07/02 By: Topstar

How to achieve micro-precision tolerances with precision injection molding machines?

Precision injection molding machines are capable of producing parts with micro-tolerances. This micro-precision tolerance (usually ±0.01 mm or less) is crucial for the production of products such as medical devices, micro-optical devices, and precision connectors. Such precision injection molding machines utilise electric drives to achieve ultra-precision motion, employ low-damping injection units to provide sensitive pressure… Continue reading How to achieve micro-precision tolerances with precision injection molding machines?

-

2025/06/27 By: Topstar

How to Ensure Scale-Free Operation in Hard Water Areas with Water-Type Mould Temperature Controllers?

Using a mould temperature controller in areas with poor water quality can cause scaling on heaters and internal channels, significantly reducing heat transfer efficiency and resulting in uneven mould temperatures, extended cycle times, and costly downtime. Therefore, achieving scale-free operation in these areas is not only an added advantage but also a prerequisite for continuous,… Continue reading How to Ensure Scale-Free Operation in Hard Water Areas with Water-Type Mould Temperature Controllers?

-

2025/06/25 By: Topstar

What defects of injection molding can the all electric injection molding machine solve?

Working with hydraulic injection molding machines is prone to injection molding defects such as warpage, material shortages, and dents, which can be reduced by switching to all electric injection molding machines. They are electrically driven and can provide tighter control over every stage of the entire process. At the same time, all electric injection molding… Continue reading What defects of injection molding can the all electric injection molding machine solve?

-

2025/06/23 By: Topstar

How to increase the injection rate of plastic molding machines?

When pursuing the goal of increasing the output of plastic molding machines during injection molding, one key factor that needs improvement is the injection rate. The injection rate is the speed at which the molten resin is pressed into the mold, and it is also one of the key factors that determine the cycle time… Continue reading How to increase the injection rate of plastic molding machines?

-

2025/06/20 By: Topstar

The trade-off between payload and speed of the injection molding robot

The key to selecting the right injection molding robot for your injection molding machine is to strike a balance between payload and speed. Payload refers to the maximum weight that the injection molding robot can carry, while speed refers to the speed at which the arm moves along its axis. Both factors directly affect cycle… Continue reading The trade-off between payload and speed of the injection molding robot

-

2025/06/18 By: Topstar

Injection molding machine manufacturers that help with intelligent upgrades

Modern factory construction requires integrated, intelligent, and data-driven quality control, as well as other planning. Therefore, as injection molding machine manufacturers providing intelligent manufacturing services to global customers, Topstar will expand its product range from hydraulic or electric injection molding machines to comprehensive intelligent upgrades. By integrating robotics, machine vision, and centralized monitoring technology into… Continue reading Injection molding machine manufacturers that help with intelligent upgrades

-

2025/06/16 By: Topstar

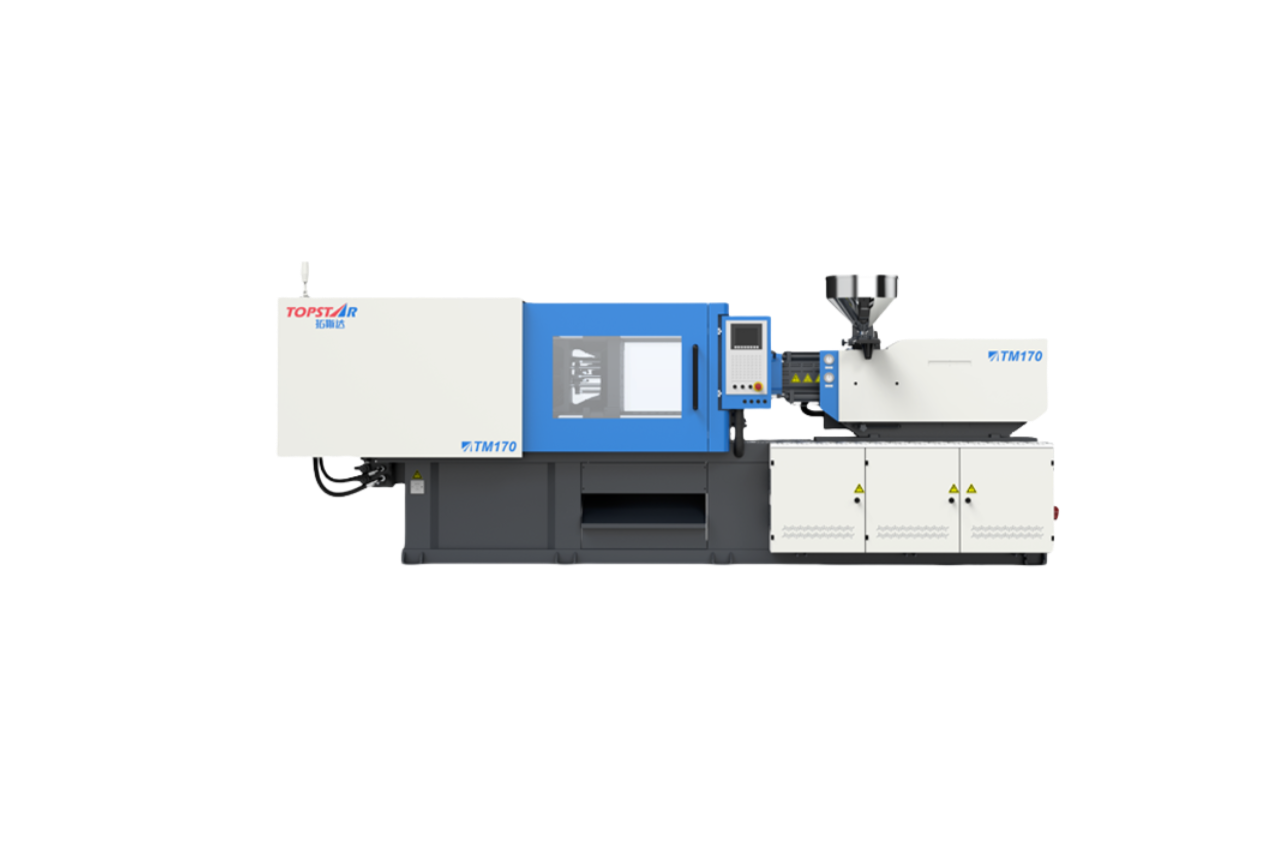

Importance of Injection Moulding Machine Frame Rigidity

Frame rigidity refers to the ability of the machine’s structural frame to resist deformation under load. When the injection moulding machine applies high clamping and injection pressures, the frame must maintain its shape to ensure the mould is accurately aligned. Any slight deviation can result in flashing, under-injection, or uneven part filling. Additionally, a rigid… Continue reading Importance of Injection Moulding Machine Frame Rigidity

-

2025/06/13 By: Topstar

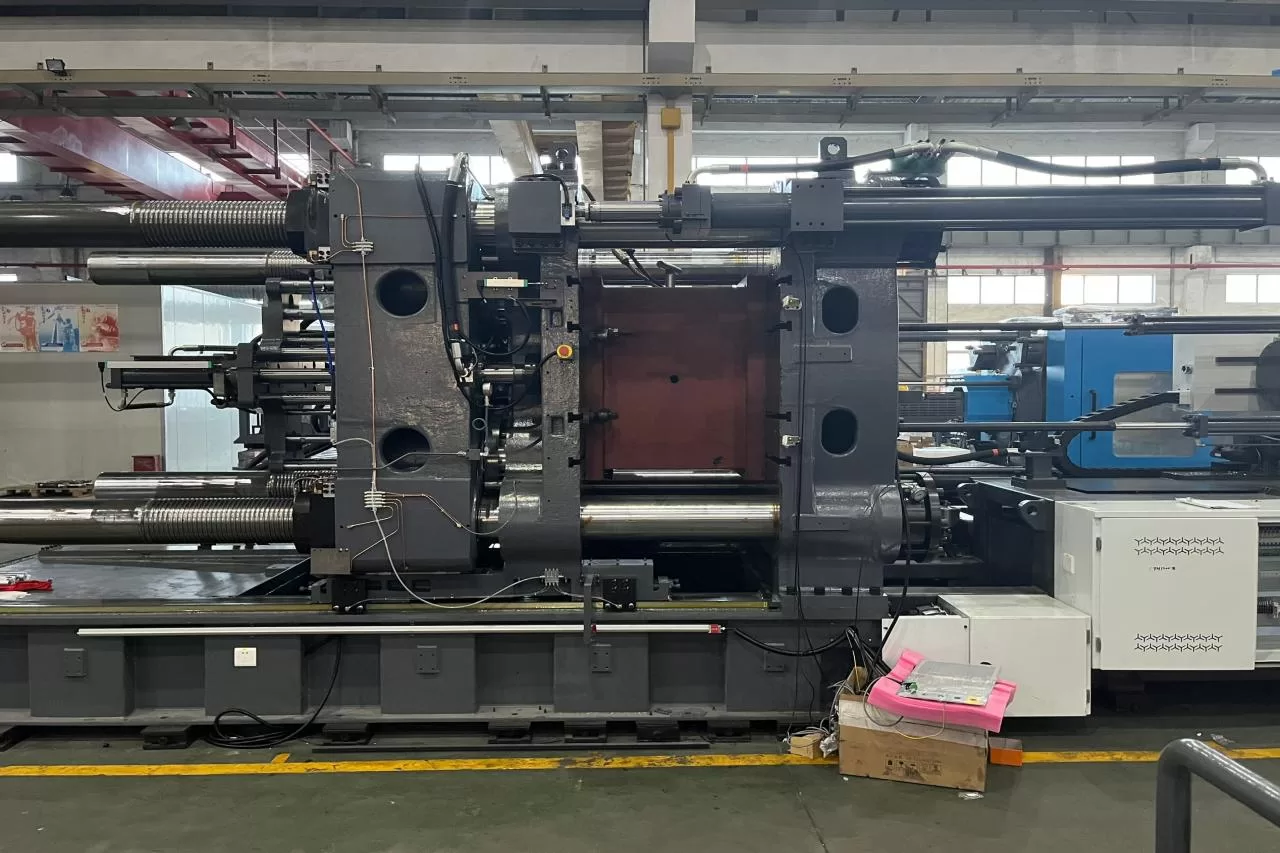

How to avoid the deviation load of a large injection molding machine?

Deviation loads are often encountered when operating large injection molding machines, where unexpected lateral forces cause the injection cylinder to deviate from its center. These loads can originate from uneven melt pressure in the injection molding machine, inconsistent clamping force, or slight wear of the guide components. When the molten plastic rushes into one side… Continue reading How to avoid the deviation load of a large injection molding machine?

-

2025/06/11 By: Topstar

Diagnosing Inconsistent Shot Weights in an All Electric Injection Molding Machine

Unlike hydraulic machines, where pressure variations and fluid compressibility can cause inconsistencies, all electric injection molding machine utilize servo motors and precision ball screw mechanisms to meter polymers. However, even these energy-efficient injection molding machines can experience shot weight fluctuations due to mechanical, thermal, or control-related factors. So we need to diagnose and eliminate the… Continue reading Diagnosing Inconsistent Shot Weights in an All Electric Injection Molding Machine