News and articles from Topstar

We are committed to the innovation and application of industrial manufacturing automation.

-

2025/06/09 By: Topstar

How to prevent the screw of plastic injection molding machine from slipping?

Screw slippage in plastic injection molding machine poses a serious threat to process stability and part quality. Slippage occurs when the screw’s flights lose their grip on the molten polymer in the barrel, resulting in inconsistent shot sizes, poor melt homogeneity, and fluctuating injection pressures. First, identify the symptoms, which typically manifest as a sudden… Continue reading How to prevent the screw of plastic injection molding machine from slipping?

-

2025/06/07 By: Topstar

Tips for checking wear of rack and pinion of injection robot?

Injection robot that are calibrated before injection molding production can ensure fast and repeatable part pick and placement. The core of one of them is the rack-and-pinion transmission mechanism. However, over time, the continuous meshing between the rack teeth and the pinion will cause metal fatigue, pitting and dimensional wear. Therefore, rack and pinion wear… Continue reading Tips for checking wear of rack and pinion of injection robot?

-

2025/06/06 By: Topstar

How to prevent overheating with proper mould temperature controller settings?

When overheating occurs in injection moulding, it affects part quality and shortens equipment life. Mould temperature controller are the central system that regulates mould temperature during the injection cycle. By maintaining a precisely controlled thermal state, they ensure consistent part dimensions, avoid defects, and optimise cycle times. When mould overheating occurs, it is usually due… Continue reading How to prevent overheating with proper mould temperature controller settings?

-

2025/06/04 By: Topstar

Analysis of the root cause of the hydraulic pressure drop of the injection molding machine

When hydraulic pressure drops in an injection molding machine, it can result in incomplete mold filling and inconsistent part dimensions. Therefore, our operators need to understand the root cause of the hydraulic pressure drop and take corresponding measures. Then, we will analyze the root cause from the perspective of the injection molding machine manufacturer. First,… Continue reading Analysis of the root cause of the hydraulic pressure drop of the injection molding machine

-

2025/05/28 By: Topstar

What is the thermal media compatibility of the mould temperature controller?

Choosing the right thermal media when using a mould temperature controller can also impact the accuracy of the final injection moulding process. Of course, not all fluids provide optimal performance across the entire operating range. Topstar mould temperature controllers are compatible with both clean and purified water, ensuring flexibility and reliability in various industrial environments.… Continue reading What is the thermal media compatibility of the mould temperature controller?

-

2025/05/26 By: Topstar

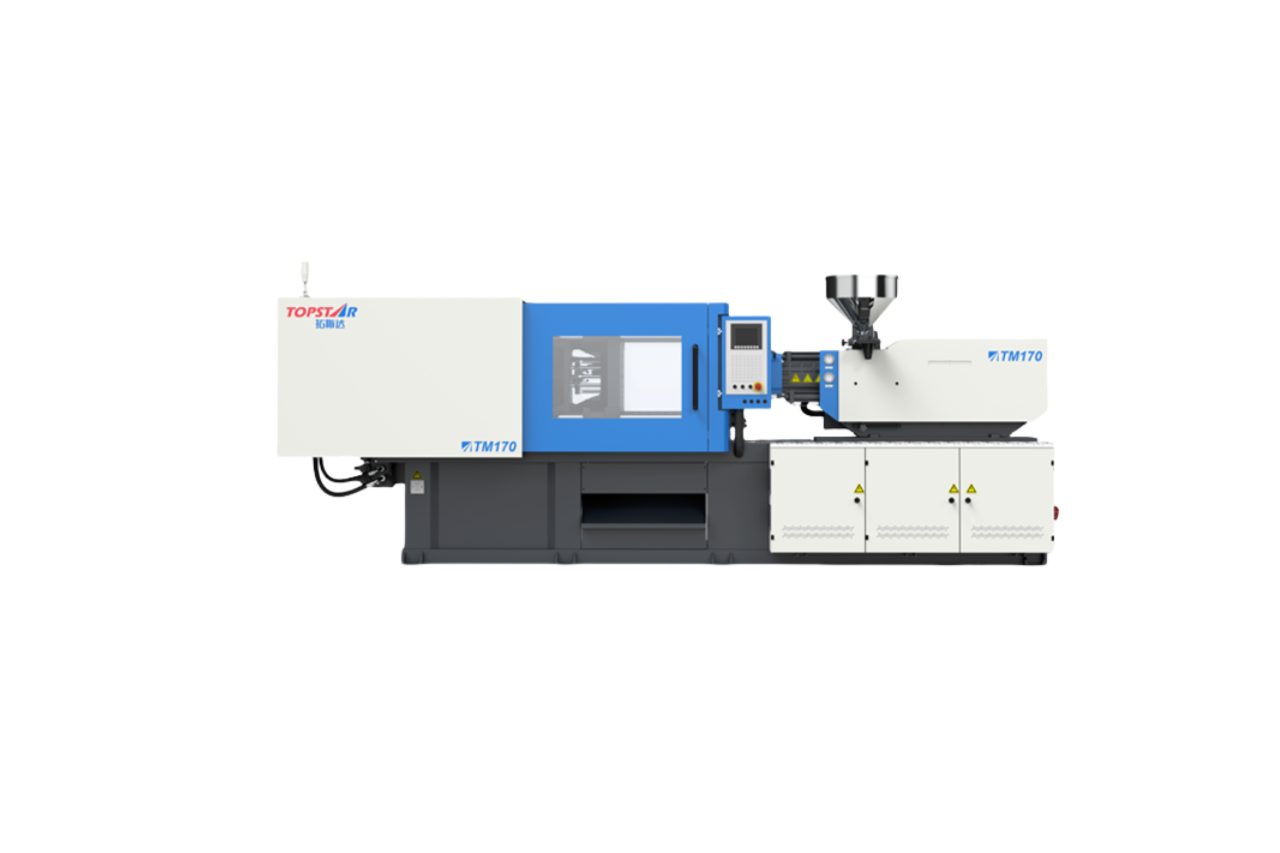

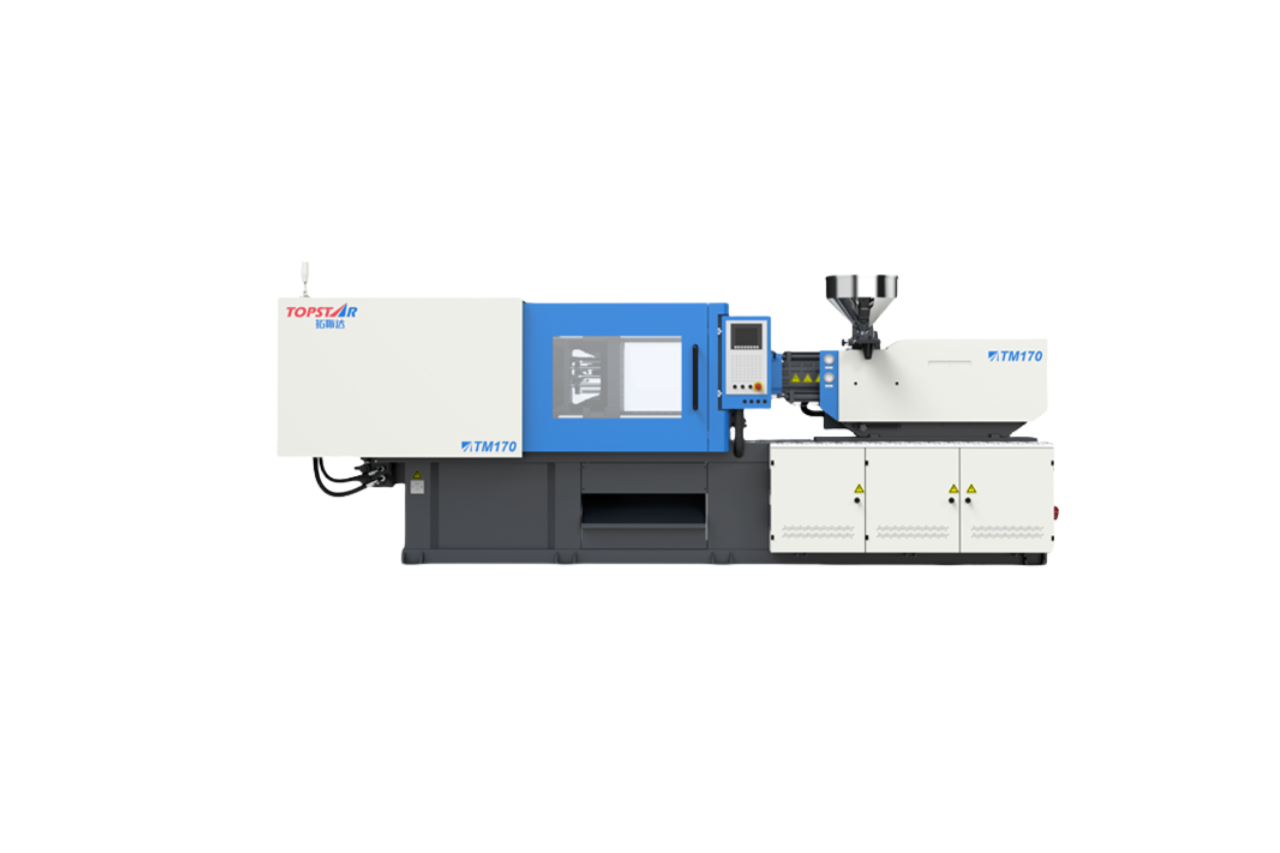

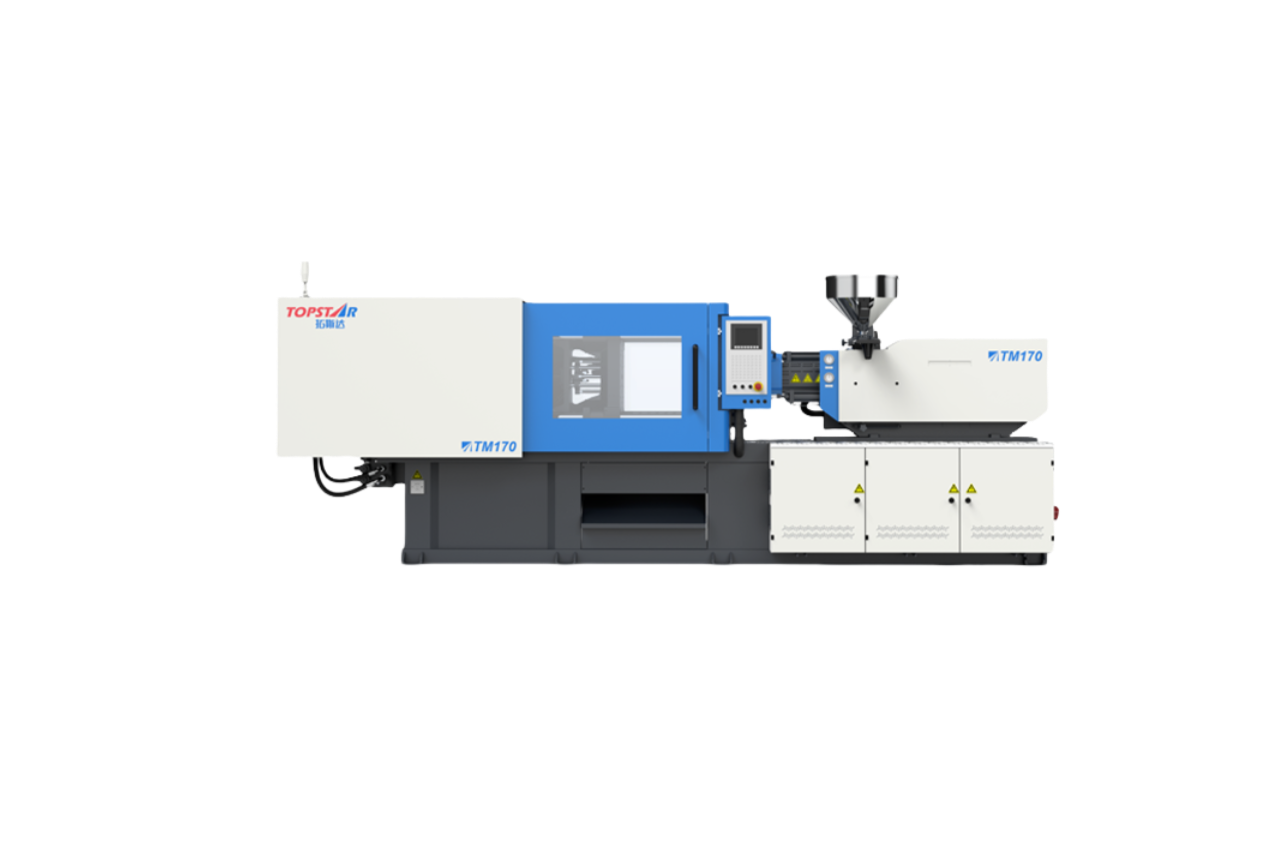

How to analyze the causes of horizontal injection molding machine failures?

Over time, horizontal injection molding machines will experience production interruptions due to mechanical, hydraulic, electrical, or process-related problems. Identifying horizontal injection molding machine failures requires a systematic approach that includes identifying failure symptoms and collecting data to identify the root cause. We will summarize several failure issues, including mechanical components, hydraulic systems, electrical controls, process… Continue reading How to analyze the causes of horizontal injection molding machine failures?

-

2025/05/23 By: Topstar

Why are servo drives better than stepper motor drives in an injection robot?

Injection robots are responsible for precise part removal, placement, and secondary operations such as insert loading, stacking, and quality inspection in injection molding. When purchasing or configuring an injection robot, there are two different drive options: a stepper motor drive and a servo drive to drive each axis, whether a simple take-out robot or a… Continue reading Why are servo drives better than stepper motor drives in an injection robot?

-

2025/05/21 By: Topstar

Solve the problems of ejection failure and mold sticking of hydraulic injection molding machine

Ejector failure and mold sticking are common problems when using hydraulic injection molding machines, which often lead to production downtime, manual part removal, and increased material waste. And these problems are particularly serious in South American manufacturing environments, where high humidity and temperature changes can exacerbate resin adhesion to the mold surface. The main reasons… Continue reading Solve the problems of ejection failure and mold sticking of hydraulic injection molding machine

-

2025/05/19 By: Topstar

Why do plastics manufacturers prefer a servo-driven 3-axis robot?

Unlike pneumatic or hydraulic robots, susceptible to compressibility, heat, and operating noise, servo-driven 3-axis robot provide clean, quiet, and highly repeatable motion with tight and precise speed control. This level of precision makes it easy to handle precision-molded parts, reduce scrap, and increase overall production. In addition, servo drives support complex motion trajectories. In high-speed… Continue reading Why do plastics manufacturers prefer a servo-driven 3-axis robot?

-

2025/05/16 By: Topstar

Do different types of mold temperature controllers have an impact on injection molding machines?

When communicating with customers at offline exhibitions and online, they often ask us questions about the impact of various mold temperature controllers on injection molding machines. As an injection molding machine manufacturer, choosing a water type or oil type mold temperature controller can significantly affect plastic injection molding machines‘ performance and production profitability. Water type… Continue reading Do different types of mold temperature controllers have an impact on injection molding machines?

-

2025/05/14 By: Topstar

Why is the preheating function of the mould temperature controller so important?

When changing moulds, operators must wait for the new mould to preheat to operating temperature and the old mould to cool completely before removing it. This waiting time is often more than 30-60 minutes, leading to lost production time. A mould temperature controller with preheating function can automatically start heating one hour before the expected… Continue reading Why is the preheating function of the mould temperature controller so important?

-

2025/05/12 By: Topstar

The importance of a 3 axis robot for injection molding in the high-speed packaging industry

When facing the injection molding production of high-speed and surging industries such as the high-speed packaging industry, it is necessary to make our injection molding equipment capable of large-order production and efficient intelligence. In addition to the core injection molding machine, a 3 axis robot is also required and integrated with the injection molding machine… Continue reading The importance of a 3 axis robot for injection molding in the high-speed packaging industry