News and articles from Topstar

We are committed to the innovation and application of industrial manufacturing automation.

-

2025/09/10 By: le zhan

The Complete Buyer’s Guide to Mold Temperature Controller Specifications and Sizing

When purchasing a mold temperature controller, consider that an improperly sized controller can lead to poor thermal stability, extended cycle times, scrapped parts, and increased repairs. Therefore, a properly specified unit can reduce cycle times through precise thermal control, improve dimensional stability, and save energy through efficient pumps and heaters. Regional factors also play a… Continue reading The Complete Buyer’s Guide to Mold Temperature Controller Specifications and Sizing

-

2025/09/08 By: le zhan

How to compare injection molding machines based on energy consumption and efficiency?

When selecting an injection molding machine for your injection molding plant, focus on energy consumption and efficiency. The energy efficiency of injection molding machines directly impacts your overall production costs and operational sustainability. Key features that influence an injection molding machine’s energy consumption and efficiency include its design, drive system, cycle time, and maintenance practices.… Continue reading How to compare injection molding machines based on energy consumption and efficiency?

-

2025/09/05 By: le zhan

How to reduce production costs through efficient plastic molding technology?

Reducing production costs in plastic molding requires optimizing every aspect of the injection molding process. Efficient molding systems, focusing on precise, fast, and energy-efficient operation, can significantly reduce waste, energy consumption, and labor costs, while also improving the consistency and quality of finished products. Adopting energy-efficient molding technologies can streamline production processes, increase output, and… Continue reading How to reduce production costs through efficient plastic molding technology?

-

2025/09/03 By: le zhan

How to reduce cycle time fluctuations through injection molding control strategies?

Achieving consistent injection molding cycle times hinges on translating every variable that influences the cycle—melt quality, cavity filling and packing, thermal conditions, mechanical motion, and material feed—into standardized, measurable, and controllable actions. When you replace manual adjustments and guesswork with closed-loop control, adaptive setpoints, and integrated monitoring, cycle-to-cycle variability decreases and production becomes predictable. Crucially,… Continue reading How to reduce cycle time fluctuations through injection molding control strategies?

-

2025/09/01 By: le zhan

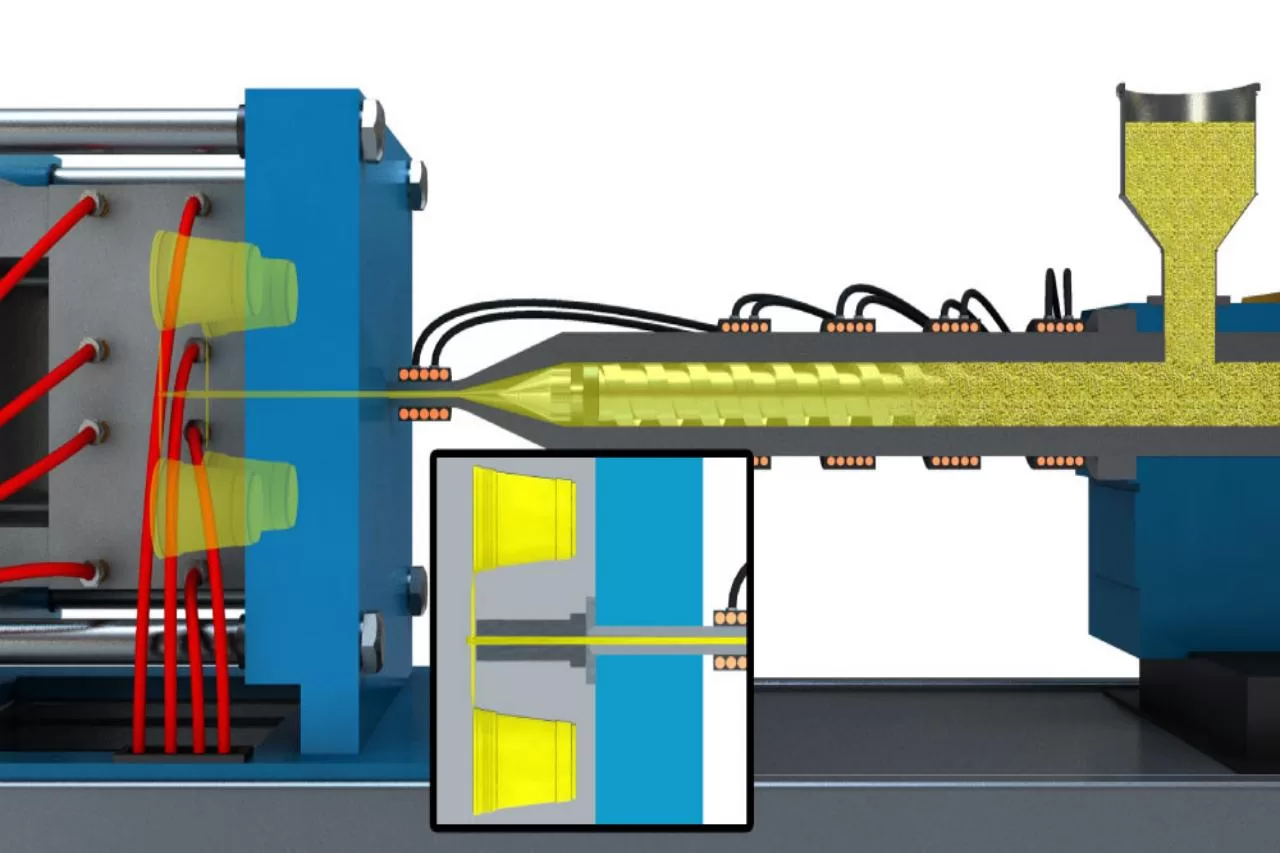

Special solution for automotive parts injection molding of PMMA thick-walled headlights

For the automotive parts injection molding of thick-walled PMMA headlights in automotive components, Topstar utilizes a direct injection molding machine equipped with a patented center-clamping mechanism. Specifically, this method enables two-shot moulding of 35 mm thick headlight lenses, significantly improving product quality and optical performance while reducing cycle time. The direct injection molding machine systematically… Continue reading Special solution for automotive parts injection molding of PMMA thick-walled headlights

-

2025/08/29 By: le zhan

How to achieve better surface gloss in optical component injection molding?

In optical component injection molding, gloss is more than just a cosmetic concern. It is directly related to surface finish, light transmittance, stray reflections, and the perceived quality of automotive, medical, and consumer optical parts. Therefore, gloss must be considered as a holistic process in production, with material, melt state, mold surface, machine precision, and… Continue reading How to achieve better surface gloss in optical component injection molding?

-

2025/08/27 By: le zhan

How can linear robots increase cycle output in thin-wall injection molding?

How can linear robots improve cycle yield in thin-wall injection molding? From a production management perspective, synchronization, precision, and a carefully designed weight-to-strength ratio are essential. Topstar’s EU Series AC Servo Injection Robots feature integrated vibration suppression, making them particularly suitable for molding thin-walled products susceptible to mold release disturbances. They can also directly receive… Continue reading How can linear robots increase cycle output in thin-wall injection molding?

-

2025/08/25 By: le zhan

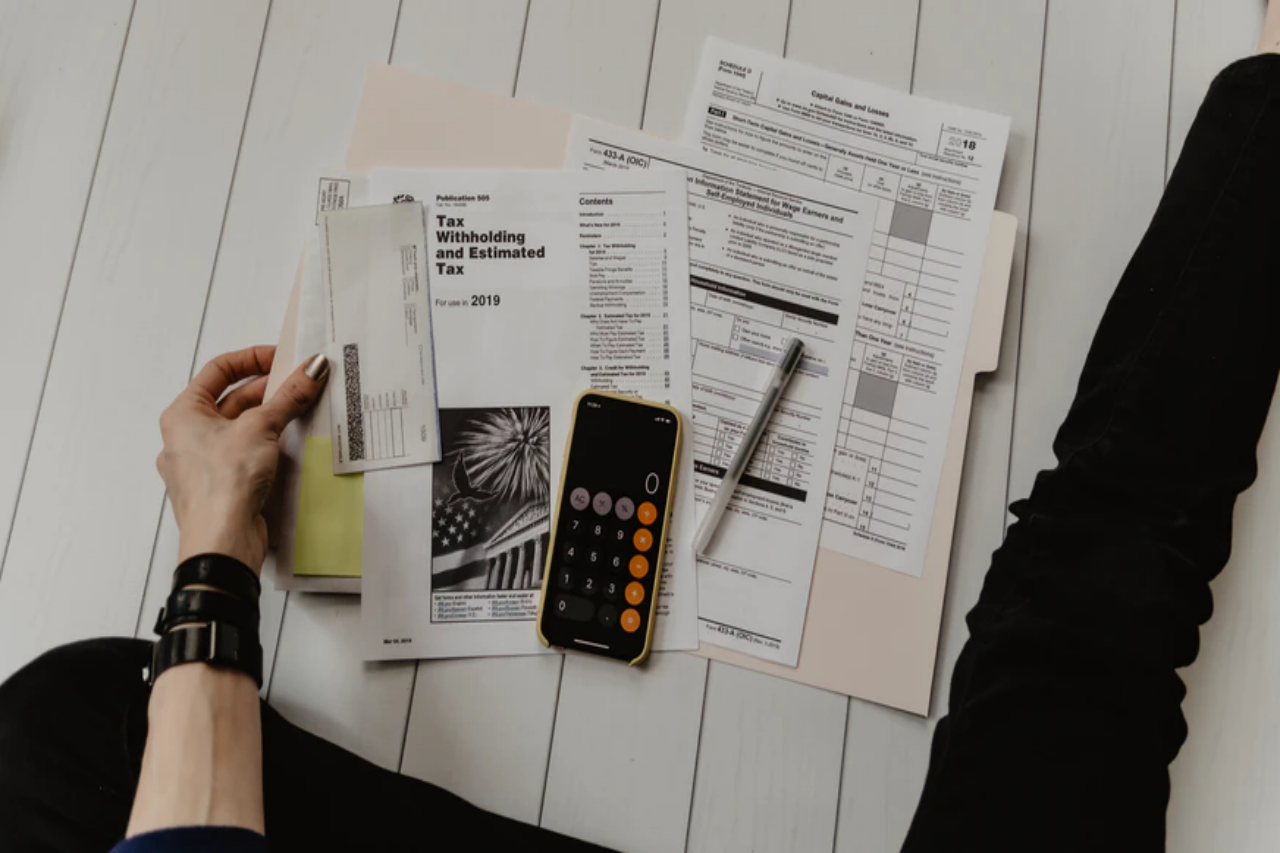

What relevant cost details should the injection molding machine manufacturer inform in advance?

Before making a purchase decision, buyers need transparent, detailed, and contextualized cost information, and receiving a quote is only the most fundamental part. During pre-purchase discussions with customers, we meticulously analyze the costs involved. The customer’s team expects a clear understanding of equipment pricing, shipping, installation, commissioning, consumables, spare parts, warranty coverage, maintenance, energy consumption,… Continue reading What relevant cost details should the injection molding machine manufacturer inform in advance?

-

2025/08/22 By: le zhan

Injection Molding Trends in 2025: AI and Smart Production Workflows

In 2025, injection molding will be an intelligent, data-driven manufacturing technology that combines sensors, algorithms, and proven electric drives to achieve scalable, repeatable quality. Topstar’s independently developed all electric injection molding machine controller has moved from the lab to customer production lines. Through deep process optimization driven by proprietary algorithms, we have observed significant improvements… Continue reading Injection Molding Trends in 2025: AI and Smart Production Workflows

-

2025/08/20 By: le zhan

Why choose to use intelligent mold temperature controller?

In the field of industrial automation control, especially in injection molding, traditional mold temperature control systems can lag behind command response, resulting in oscillation, slow settling, or steady-state errors. These hysteresis and delay are not abstract interference factors; they are key drivers of scrap, longer cycle settling times, and unpredictable dimensional variations. Traditional PID loops… Continue reading Why choose to use intelligent mold temperature controller?

-

2025/08/18 By: le zhan

How to plan the factory layout of multiple injection moulding equipment units?

When we deploy multiple injection moulding equipment in a customer’s factory, we’re not just planning the layout; we’re building a manufacturing ecosystem. Good planning translates floor space into predictable output, repeatable quality, and manageable costs. Consider a medium-sized injection moulding plant with ten injection moulding machines and a target monthly production volume of 500,000 parts.… Continue reading How to plan the factory layout of multiple injection moulding equipment units?

-

2025/08/16 By: le zhan

What kind of clamping system is needed for large injection molding machine with high clamping force?

For the large injection molding machine that require high clamping forces, the clamping system has a significant impact on production accuracy, uptime, and safety. In fact, for large-tonnage, high-clamping-force injection molding machines, we utilize a multi-cylinder direct pressure clamping design. This approach expands clamping capacity without concentrating the load on a single actuator. It improves… Continue reading What kind of clamping system is needed for large injection molding machine with high clamping force?