Ejector failure and mold sticking are common problems when using hydraulic injection molding machines, which often lead to production downtime, manual part removal, and increased material waste. And these problems are particularly serious in South American manufacturing environments, where high humidity and temperature changes can exacerbate resin adhesion to the mold surface. The main reasons… Continue reading Solve the problems of ejection failure and mold sticking of hydraulic injection molding machine

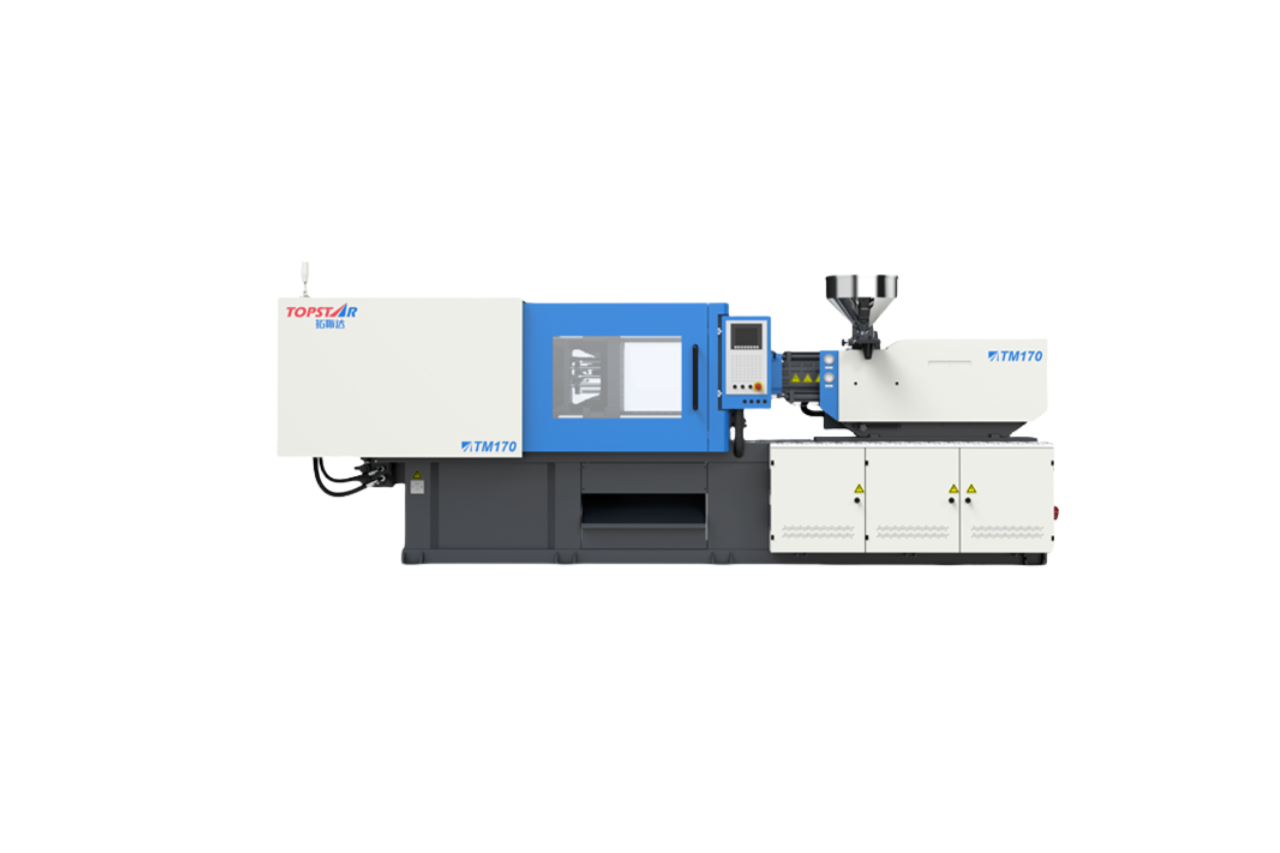

Solve the problems of ejection failure and mold sticking of hydraulic injection molding machine