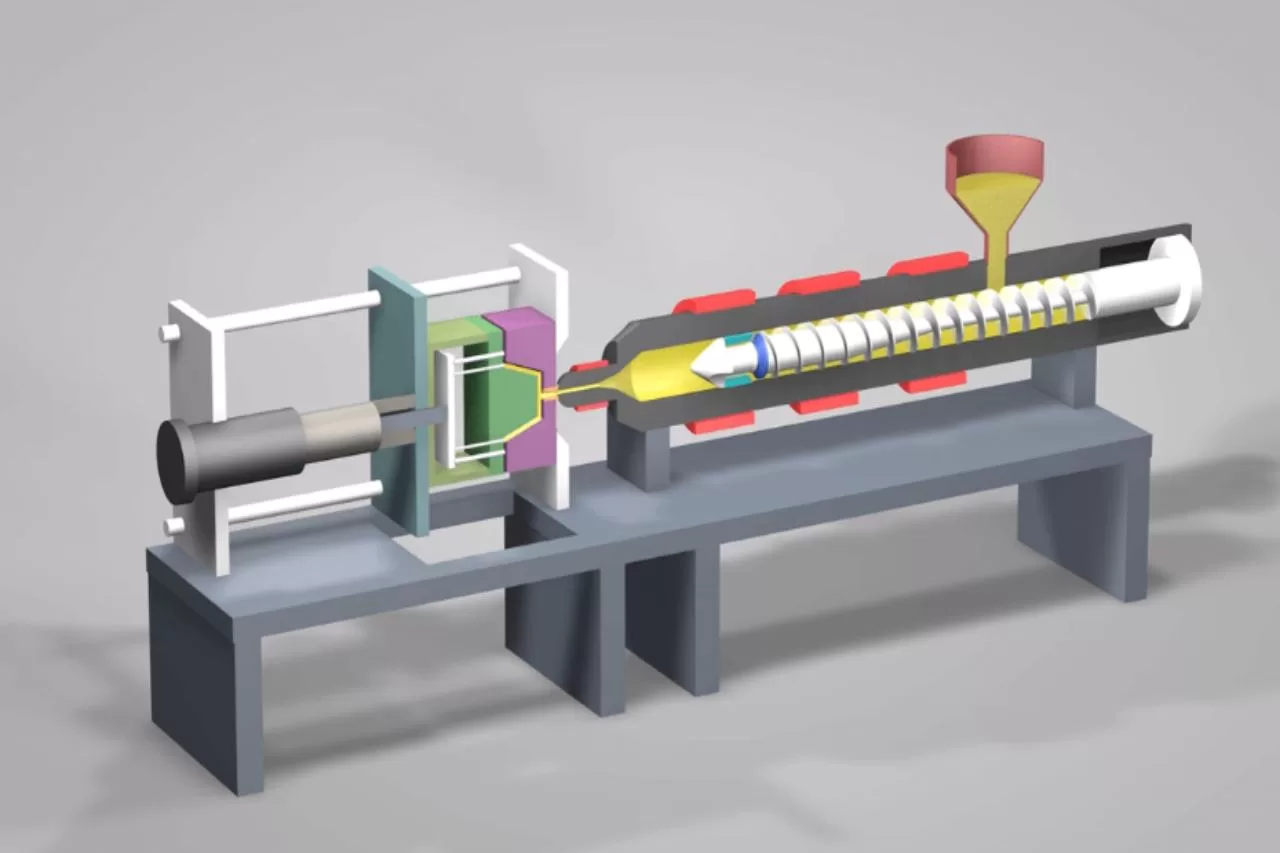

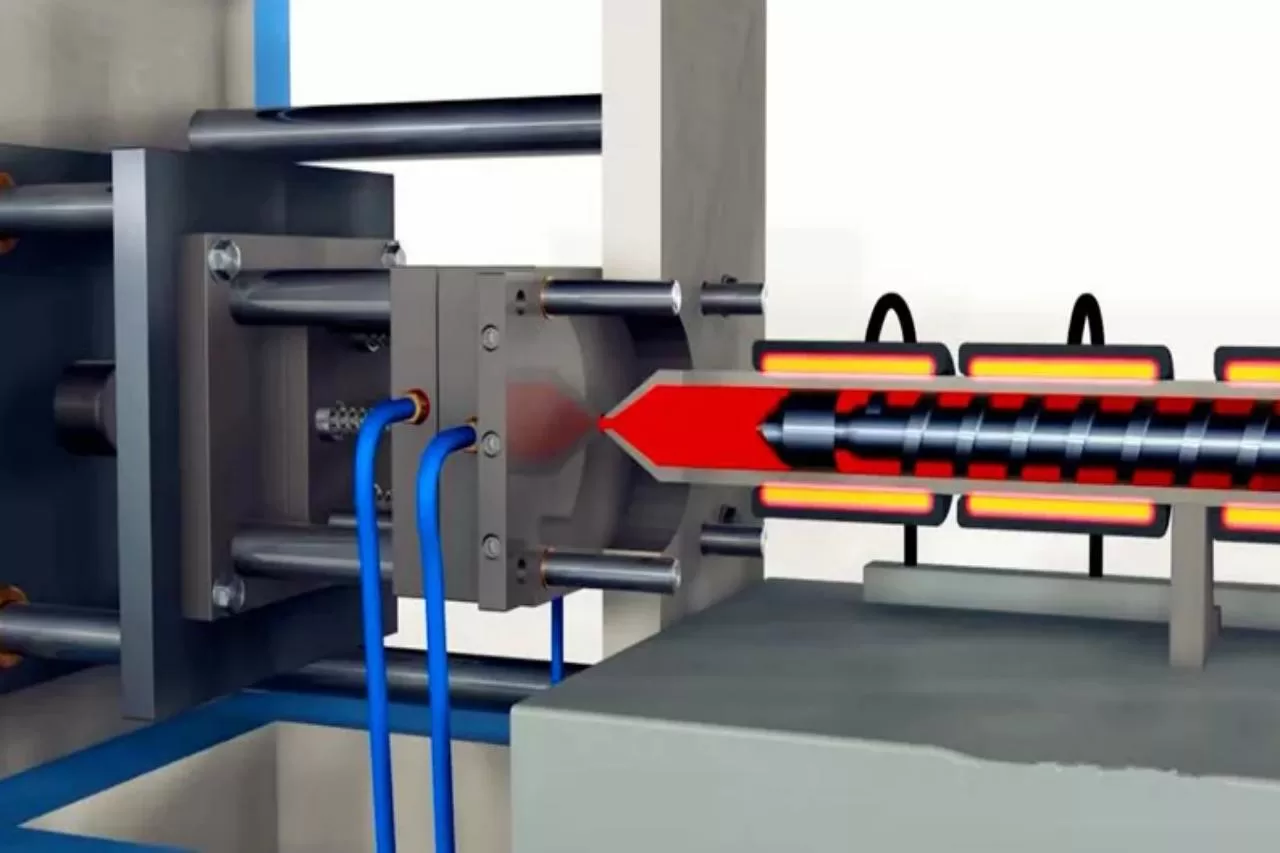

Hydraulic and electric injection molding machines offer distinct process conditions for injection molding. Their differences lie in their mechanical design, with oil pumps and valves versus servo motors and ball screws. Still, the real impact extends to cycle time, repeatability, energy consumption, and part quality. This helps you understand which injection molding machine is best… Continue reading Differences between hydraulic and electric machines in injection molding process

Differences between hydraulic and electric machines in injection molding process