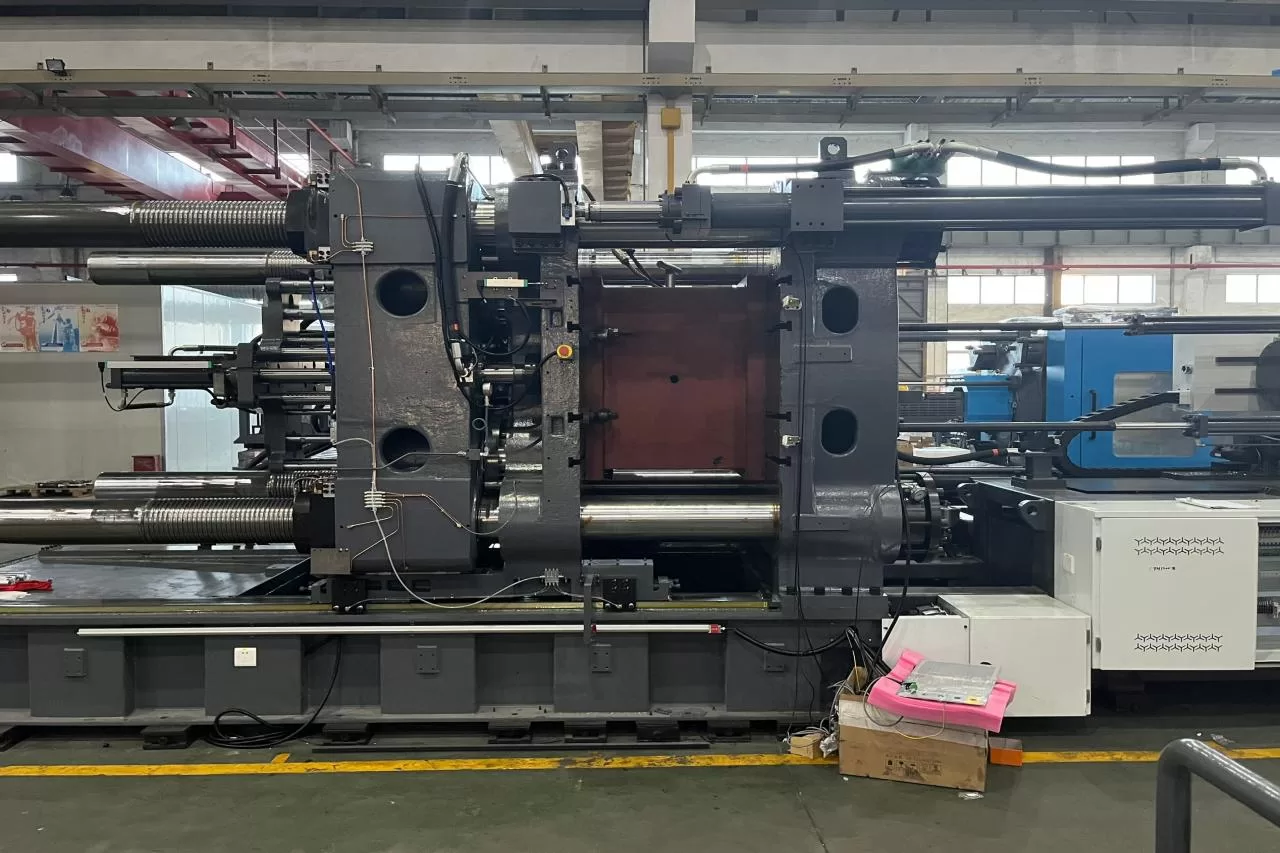

Weld line defects in injection moulding account for 25% of cosmetic and structural part failures and are the most common problem encountered by customers. Weld lines are formed when two melt fronts meet, and poor melt conditions can result in poor bonding or visible flaws. Troubleshooting this type of failure begins with determining the exact… Continue reading How to Troubleshoot Weld Line Failures on Plastic Injection Moulding Machine?

How to Troubleshoot Weld Line Failures on Plastic Injection Moulding Machine?