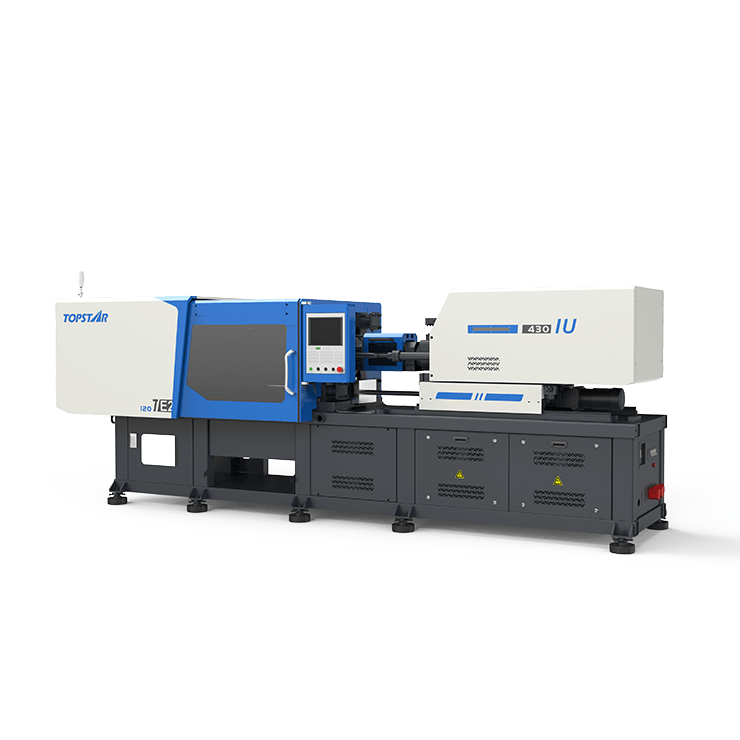

All Electric Injection Molding Machine(90T-460T)

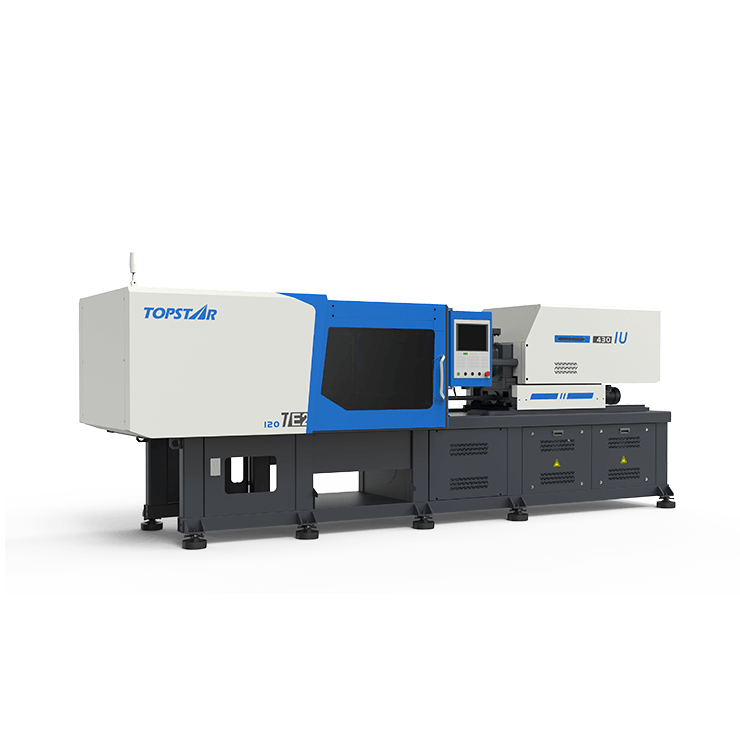

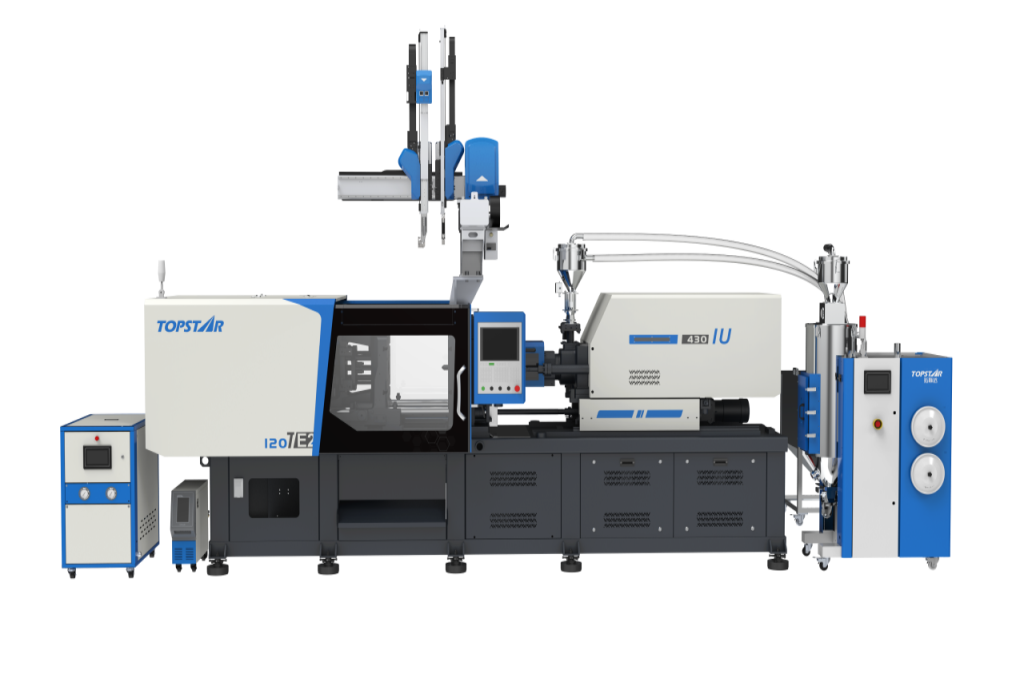

Topstar TEII Series:All Electric Injection Molding Machine (90T-460T) TEII series all-electric injection molding machines have TE II all-electric and h-TE Il hybrid share platforms. Their clamping units have high-rigidity templates to stabilize the product and better protect the mold. The popular modulus design can meet the mold installation needs; Optional linear rail support makes movement lighter. The modular design of the injection unit can adapt to various working conditions. Has a humanized interactive interface.

Characteristics

- 1. Low-damping injection unit for precise metering

- 2. The Servo self-driven motor runs at a very low speed and smoothly, and it can eliminate product flow marks.

- 3. High-precision pressure control, with a low-damping injection unit, to improve product stability.

- 4. High rigidity and low friction mechanical structure for precision molding.

- 5. Non-contact tie rod, The tie rod does not need lubrication, reduces pollution, and avoids strain on the column and movie mold linear guide.

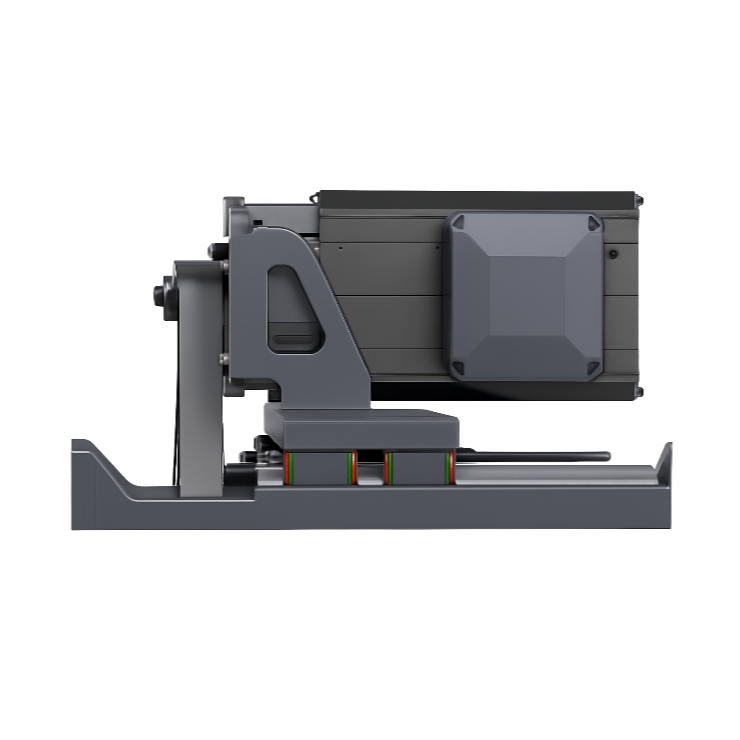

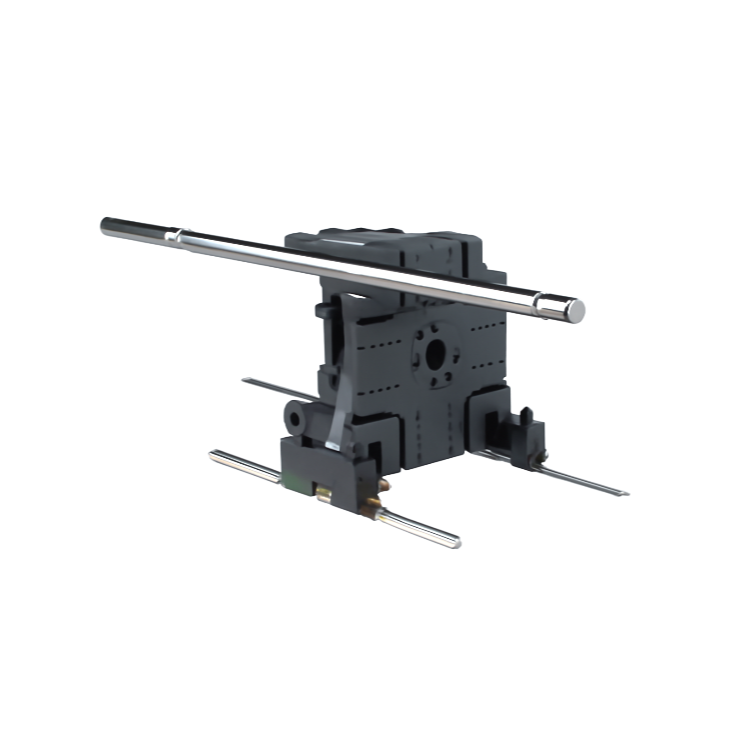

Product Accessories

- 1. Wide support for platen and mold, stable dynamic support, stable mould opening and closing, and better protection of mould and machine.

- 2. High rigidity platen, full stress analysis, appropriate strength design.

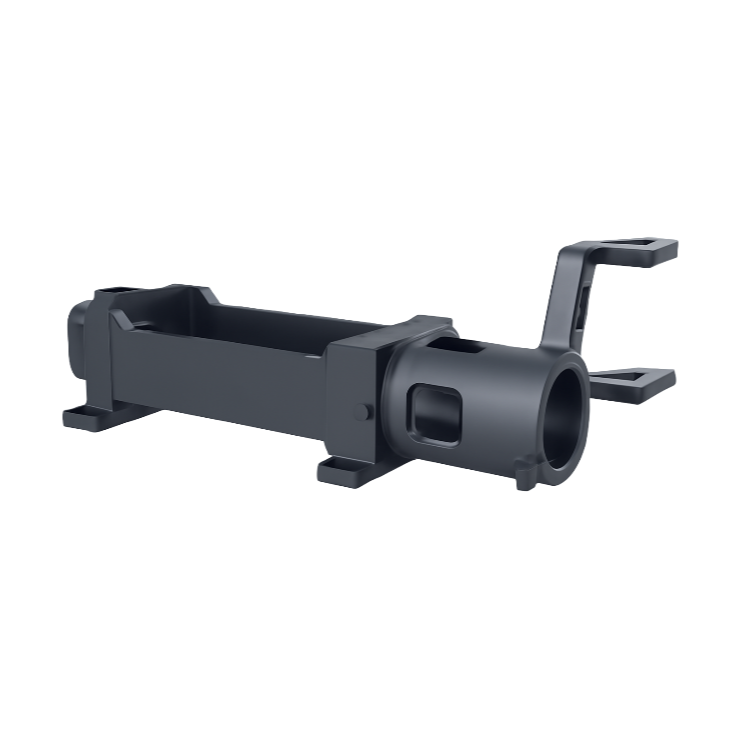

- 3. Integrated injection unit, high rigidity, stable structure, more precise control.

- 4. Linear guide rails, low damping, more sensitive pressure detection, and more precise pressure control.

Technical Specifications:

| Specification | Parameter |

| Clamping Force | 60 – 460 Ton |

| Injection Type | Electric / Hybrid (e-TEII / h-TEII) |

| Screw Diameter | 22 – 80 mm |

| Max. Injection Speed | Up to 500 mm/s |

| Injection Unit Options | IU / IUh / IUhs (Low / Medium / High Speed) |

| Mold Opening Stroke | 320 – 790 mm (Model dependent) |

| Tie Bar Distance | Up to 910 × 910 mm |

| Mold Height Range | 150 – 810 mm |

| Max. System Pressure | 16 – 17.5 MPa |

| Oil Tank Capacity | 90 – 184 L |

| Ejector Force | Hydraulic / Electric (Optional) |

| Control System | 12-inch Touch ScreenMulti-language (CN / EN), SPC Quality Monitoring Mold Data Storage |

| Application Industries | Medical · 3C Electronics · Toys · Auto Parts · Home Appliances · Cosmetics |

Adequate supply of goods, available for delivery within 35 days. You can consult the all electric injection molding machine price at any time.

Description

Intelligent electric mold opening and closing

Intelligent electric mold opening and closing technology replaces hydraulic systems with precision electric drives to achieve faster and smoother mold opening and closing. This intelligent mechanism minimizes mechanical wear and virtually eliminates oil leakage and vibration problems.

Realizing a digital public platform

The all-electric injection molding machine realizes fast data transmission and coordinated control between various control units. The digital control method can accurately monitor and control various parameters in the injection molding process, improving production efficiency and stability.

High-speed servo drive and reduced delay

Discrete intelligent drive control acts directly on the servo motor to minimize communication delays during high-speed cycles. This real-time feedback loop optimizes position, speed and pressure control for optimal performance.

Integrated and flexible process adjustment

The all electric injection molding machine follows the concept of "injection molding process all-in-one machine" and can adjust multiple parameters in real time to adapt to different materials and geometries. Customizable control strategies ensure stable and accurate molding in various applications.

[sc name="topstar" ][/sc]