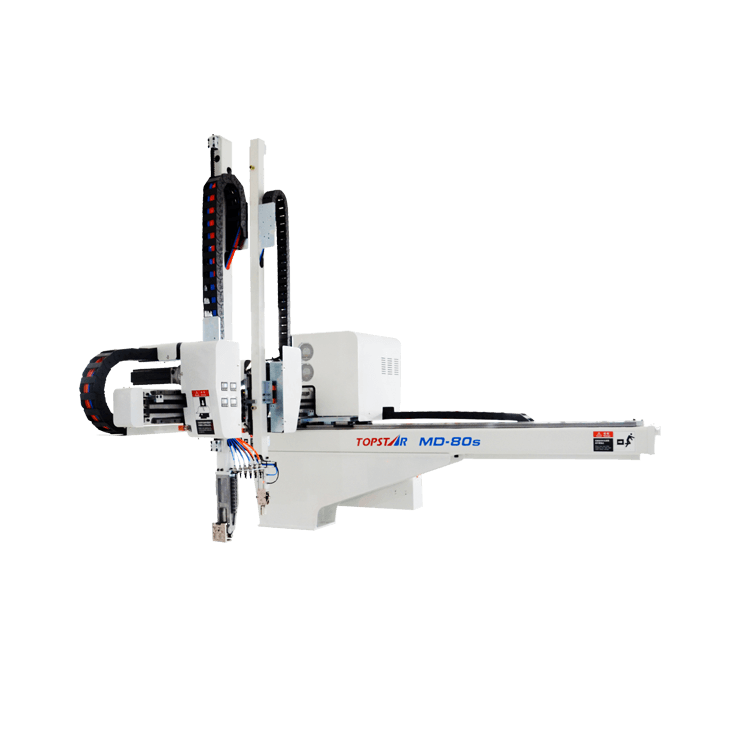

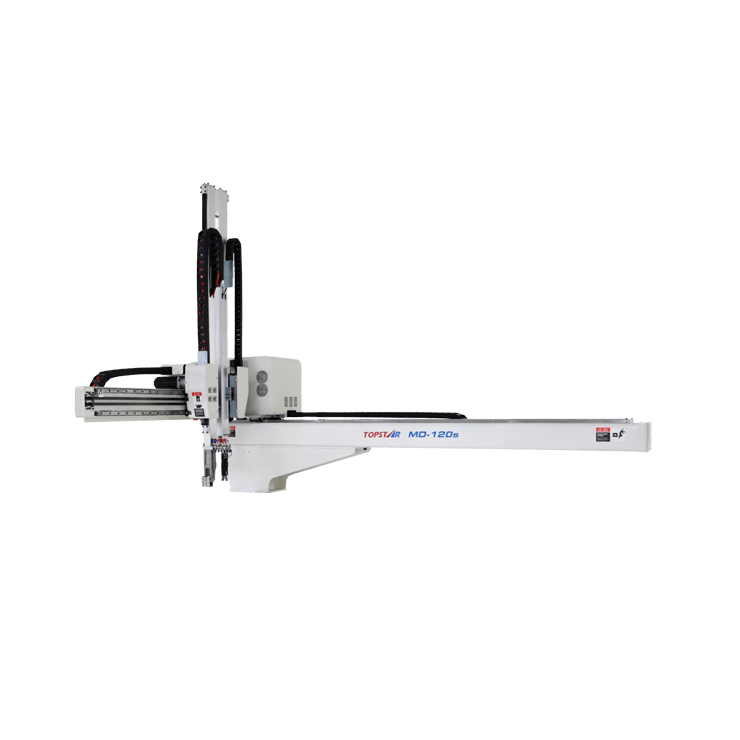

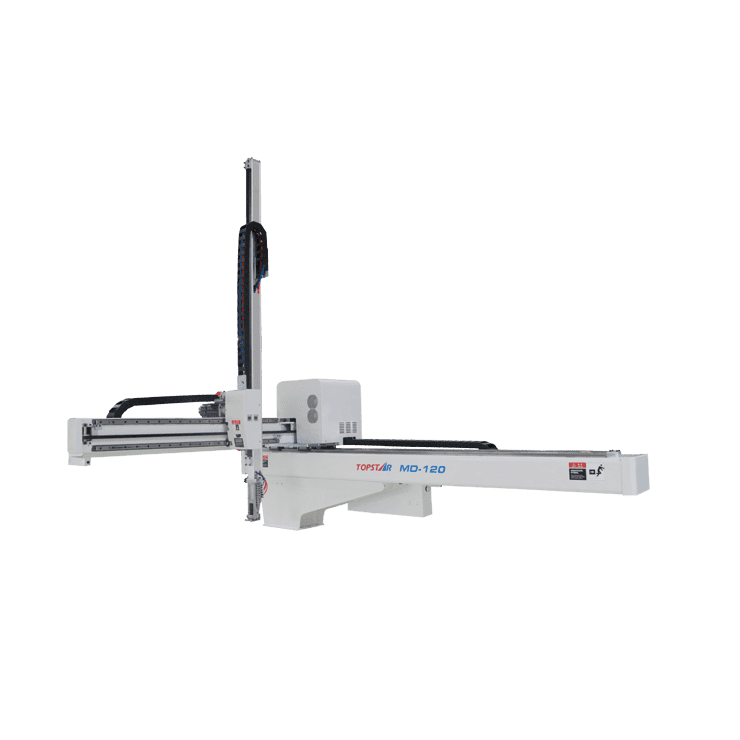

MDE Series AC Servo Injection Robots

The Topstar MDE series 3axis/5axis AC servo injection molding robots are high-precision, high-speed automated robotic arm solutions designed specifically for 30 to 550-ton injection molding machines. This series of injection molding robots features a robust Q235 steel arm structure, AC servo drive technology, and an intelligent control system, enabling superior positioning accuracy, fast cycle times, and excellent energy efficiency. The MDE series supports MODBUS RTU communication, multi-axis flexible motion control, and the Topstar Link remote monitoring platform, allowing for automated part removal and insert molding, making it ideal for efficient and intelligent factories.

Features

High precision:

- The main arm is made of Q235 material, with a Stable structure and high repeatability, enabling it to meet various non-standard insert motions.

High speed:

- Optional imported Domawa motor (rotation speed can reach 6000r/min). The maximum rotation speed increases by 10%, and the acceleration and deceleration time is reduced by 20%.

High energy-saving effect:

- Total DC bus technology saves 10% in energy and reduces electricity costs by 10%. Add the servo drive automatic OFF function, stopping the servo motor power when the robot is in standby status, saving 10% of electricity.

High performance:

- Control system independent research, irregularly updated software, can be upgraded for life, and can be developed and customised according to customer needs.

- Built-in duarsystem, customer-free dholce.

- Add a softening function to each axis to prevent the robot from failing to pick products or breaking the arm when the old opening position changes.

- Standard RS-485 communication interface, supports the MODBUS RTU communication protocol.

- Standard2 vacuum circuit 2 air circuit function, reserve 11 inputs and 11 outputs.

Topstar link application platform:

- Real-time remote monitoring, data statistics, analysis, and life management of equipment operations.

Optional series

-

1.MDE-50 V (suitable for 30-100IMM tons)

-

2.MDE-50s V (suitable for 30-100IMM tons)

-

3.MDE-80 V (suitable for 100-300IMM tons)

-

4.MDE-80s V (suitable for 100-300IMM tons)

-

5.MDE-120 V (suitable for 350-550IMM tons)

-

6.MDE-120s V (suitable for 350-550IMM tons)

Adequate supply of goods, available for delivery within 35 days.

Description

High-Precision, High-Efficiency Intelligent Injection Robot Solution

Wide Injection Molding Machine Compatibility:

- Suitable for small and medium-sized injection molding machines ranging from 30 to 550 tons.

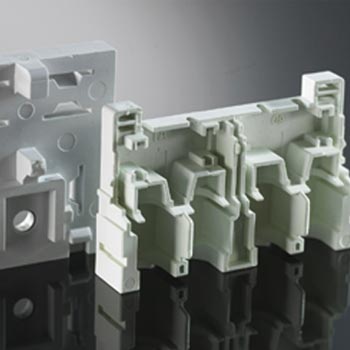

High-Precision Mechanical Structure:

- The main arm is made of Q235 high-strength steel, ensuring excellent rigidity, long-term stability, and high repeatability, suitable for complex and non-standard insert molding applications.

High-Speed AC Servo Drive System:

- Optional imported high-performance servo motor with speeds up to 6000 rpm, increasing rotation speed by 10% and reducing acceleration/deceleration time by 20%.

Energy-Saving Servo Technology:

- Utilizes full DC bus technology and automatic servo power-off function, reducing overall energy consumption by approximately 20% during operation and standby.

Intelligent Control System:

- Independently developed controller with lifetime software upgrade capability, customizable logic, and optional dual-system configuration to meet diverse automation needs.

Stable and Safe Motion Control:

- Multi-axis softening function effectively prevents missed picks or mechanical arm damage caused by changes in mold opening position.

Flexible I/O and Pneumatic Configuration:

- Standard 2 vacuum circuits + 2 air circuits, with 11 inputs and 11 outputs reserved, supporting flexible peripheral device integration.

Industrial Communication Capability:

- Standard RS485 interface supports MODBUS RTU protocol, enabling seamless integration with injection molding machines and factory automation systems.

Topstar Link Intelligent Platform Support:

- Enables real-time remote monitoring, production data statistics, performance analysis, and equipment lifecycle management for intelligent manufacturing.