Feeding and Conveying System

An auto loader automatically transfers plastic granules or pellets from a hopper, bag, or central storage system to the injection molding machine hopper. Topstar’s autoloader series includes Single, Detachable, Open Type Detachable, and Hopper Receivers. These autoloaders provide clean, stable, and efficient material handling. They all feature stainless steel construction, intelligent control systems, reliable motor protection, and high-efficiency filtration to ensure contamination-free material feeding, reduced downtime, and consistent molding quality. With flexible configurations and strong compatibility, they are ideal for material handling in automated, digital, and high-efficiency plastic processing environments.

Features

- 1. The main controllers and material hopper receivers are designed separately.

- 2. Can match 2 or above 2 hopper receivers to achieve one to multi combination conveying.

- 3. Material conveying capacities can be up to 700kgs/hr.

- 4. The maximum loading distance can be 10m, suitable for conveying materials over long distance.

Application Industries

- 1. Electronics

- 2. Containers

- 3. 3C home appliances

- 4. Cosmetics

- 5. Auto parts

- 6. FMCG

Adequate supply of goods, available for delivery within 35 days.

Description

TAL Series Single Autoloaders

TAL Series Single Autoloaders are designed for compact installation directly on injection molding machines, delivering clean, efficient, and highly reliable material feeding. Its full stainless steel construction ensures contamination-free handling of plastic pellets, while the motor protection system significantly extends service life. Equipped with a dual-layer filtration system combining fabric and stainless steel mesh, along with a motor-reverse dust-cleaning function, this autoloader effectively reduces dust accumulation and reduces maintenance frequency. The integrated intelligent sensing technology ensures accurate material delivery and provides automatic alerts for material shortages.

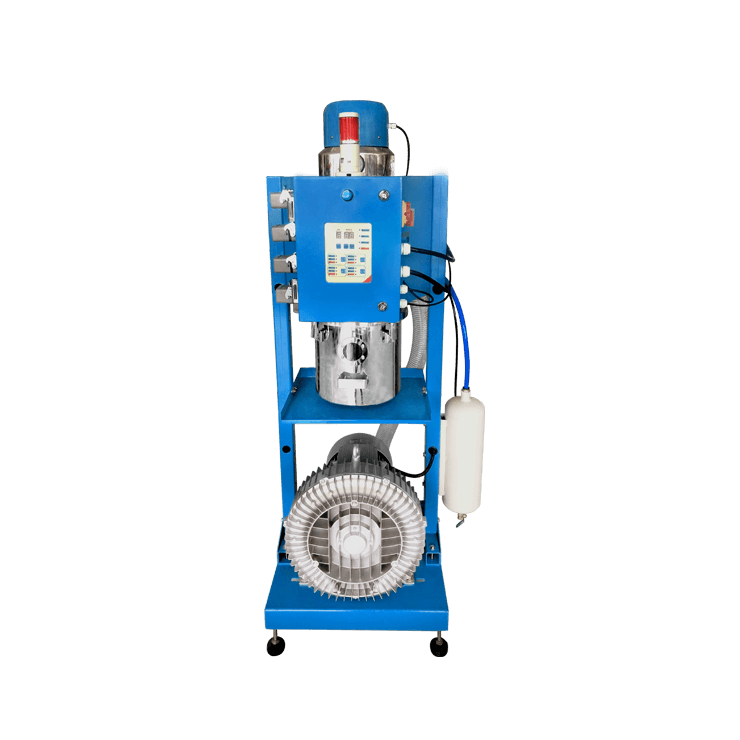

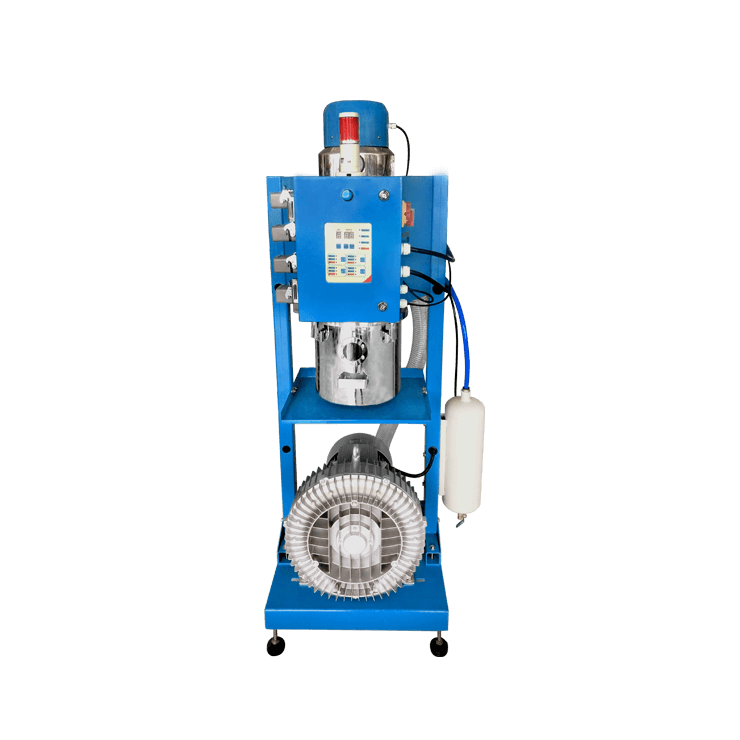

TAL Series Detachable Autoloaders

TAL Series Single Autoloaders main controllers and material hopper receivers are designed separately for safety & convenient purpose, allowing 2 or more hopper receivers to be combined for one-to-many conveying. It greatly enhances material conveying capacity up to 700 kg/hr. The maximum loading distance is 10m. The independent filtration system and optional cyclone separator significantly reduce dust load and cleaning frequency, ensuring efficient operation even when conveying crushed materials. All models are suitable for conveying materials over long distances and for easy operation, satisfying customers’ various requirements.

TAL Series Detachable Autoloaders(Open type)

The Topstar TAL Series Detachable Autoloader (open type) combines European-style industrial design with intelligent control and efficient dust management. Manufactured from stainless steel, it ensures clean material conveying without contamination while enhancing the visual appeal of the production environment. The loader uses a downward-suction airflow design with a cyclone baffle and a separate dust-collection barrel, significantly reducing filter load and improving long-term operational stability. With single-stage or dual-stage blower options and compatibility with multiple hopper configurations, this open-type autoloader is ideal for high-efficiency, safe, and intelligent injection molding operations.

Hopper Receivers

Hopper Receivers are fitted with sensors to control material suction smoothly. Diverse Hopper Receivers - standard type, stainless type, and optic type are provided according to customers’various requirements. Stainless-steel shoppers ensure no contamination of raw materials, and they are equipped with a see-through window to monitor material levels, which are especially suitable for the application. optics. They can be mounted directly onto plastic injection molding machines or with separate autoloaders, providing more convenient cleaning or changing.

Including: FSR Series Optics Stainless Steel Hopper Receivers, SR Series Stainless Steel Hopper Receivers, CSR Series Central Stainless Steel Hopper Receivers. MR Series Magnetic Induction Hopper Receivers.