Drying and Dehumidifying System

Topstar drying and dehumidification systems are specifically designed for injection molding applications, providing precise humidity control, stable low-dew-point drying, and contamination-free material handling. These dryers and dehumidifier dryers utilize PID temperature control, energy-efficient airflow design, stainless steel construction, and comprehensive safety features to effectively improve product quality while reducing energy consumption. From standard hot air dryers to advanced three-in-one drying systems and nitrogen dehumidification systems, Topstar offers reliable drying solutions for hygroscopic plastics, optical-grade plastics, and high-performance plastics.

Features

- 1. 3 in 1 compact dehumidifying dryers are equipped with honeycomb rotor which can acquire stable low dew-point drying air.

- 2. To integrate the function of dehumidifying , drying and two-stage conveying into single unit. Three-stage conveying function is optional.

- 3. Double-wall insulated hopper dryers features down-blowing pipe design to avoid heat dispersion for improving drying efficiency.

- 4. Feeding system is equipped with shut-off valve to ensure noremaining material in hopper tube.

- 5. Multiple safety protection device.

- 6. Optical-class models use mirror polished treatment on the material contact surface to avoid material contamination and collocate feeding system with closed-loop in order to avoid the possibility of moisture regain for absorbingoutside air during material conveying.

Application Industries

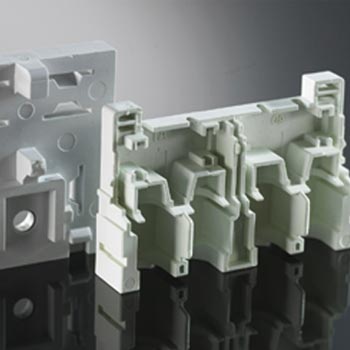

- 1. Electronics

- 2. Containers

- 3. 3C home appliances

- 4. Cosmetics

- 5. Auto parts

- 6. FMCG

Adequate supply of goods, available for delivery within 35 days.

Description

THD Series Hot Air Dryer

The Topstar THD series hot air dryer is suitable for drying standard plastic materials in injection molding. It features a 1°C temperature resolution and a PID auto-tuning function, ensuring stable and precise temperature control. The top-mounted hot air diffusion system evenly distributes heat throughout the material, accelerating drying speed and improving drying consistency. All parts in contact with the material are made of stainless steel to prevent contamination, and a built-in over-temperature protection function ensures safe operation. Furthermore, the THD series hot air dryer utilizes simple button controls and clear alarm codes, providing stable performance, convenient operation, and reliable drying quality.

THDP Series Hot Air Dryer

The Topstar THDP series hot air dryer is an upgraded hot air drying solution designed for improved efficiency, intelligent control, and energy savings. In addition to PID temperature control with 1°C accuracy, it supports weekly timer programming and offers an optional RS485 communication interface and MODBUS RTU protocol for smart factory integration. The double-layer insulated heating and drying module reduces energy loss and enhances operator safety, while the specially designed flared air outlet improves convection between the material and hot air for more thorough drying. Comprehensive safety monitoring features include fan phase loss, reverse rotation, overload detection, and over-temperature trip protection.

TCD Series Cabinet Dryers

The TCD series cabinet dryer is designed for efficient and uniform batch drying of various plastic materials. Equipped with a PID temperature control system, it ensures consistent drying results across all trays; the high-temperature sealed door minimizes heat loss and reduces energy consumption. Stainless steel trays prevent material contamination, and the hot air circulation and recovery system significantly improves energy efficiency. Features such as adjustable air dampers, over-temperature protection, motor overload alarm, and a 24-hour timer ensure flexible and safe operation. The TCD cabinet dryer also features a mobile trolley design, making it ideal for factory workshops that require a versatile, energy-efficient drying solution.

TDH Series Honeycomb Rotor Dehumidifiers

The Topstar TDH series honeycomb rotor dehumidifiers are designed specifically for injection molding applications using hygroscopic plastics, providing high-performance humidity control. These dehumidifiers utilize a silica-gel honeycomb rotor to deliver stable, low-dew-point air below –40°C, with a lower regeneration temperature (180°C), resulting in significant energy savings compared to molecular-sieve systems. The dual-cooler design ensures lower supply air temperature and more stable dew-point performance, while the integrated return-air filter protects the rotor from dust contamination. With their compact design, high-quality components, and long service life, the TDH series dehumidifiers provide a reliable, energy-efficient solution for precision injection molding.

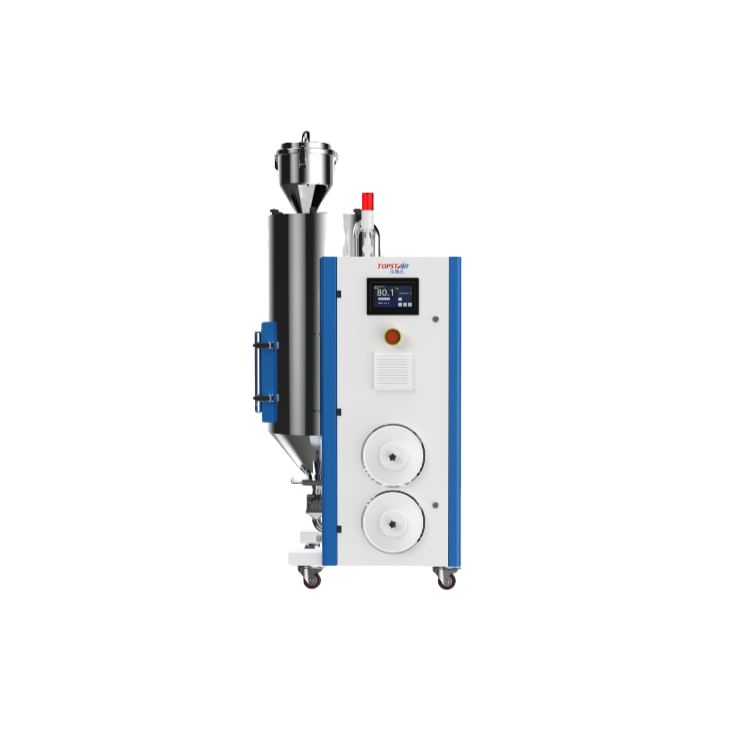

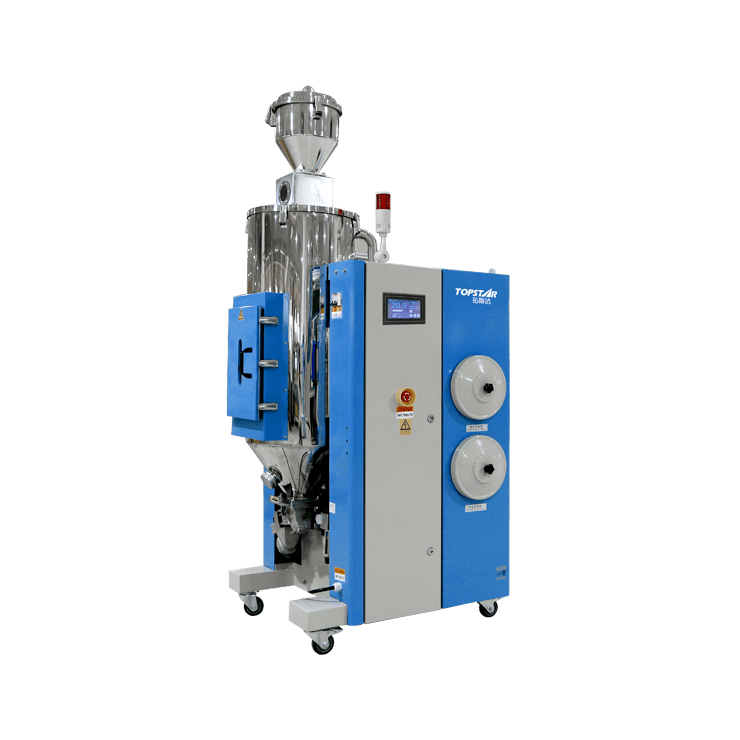

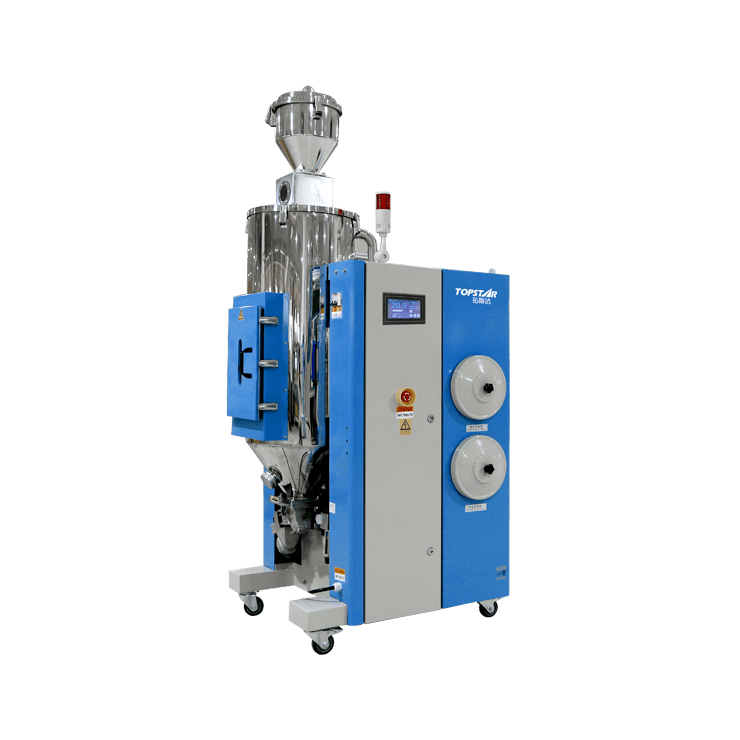

TCDE Series 3 in 1 Compact Dehumidifying Dryers (Energy-Saving Type)

The TCDE series 3 in1 compact dehumidifying dryer integrates dehumidification, drying, and two-stage (or optional three-stage) conveying functions into a single, highly efficient and energy-saving unit. It continuously supplies dry air with a dew point as low as -40°C, significantly improving the quality of hygroscopic and optical-grade plastics. The double-layered insulated drying hopper features a downward airflow design to minimize heat loss and improve drying efficiency; the fully enclosed conveying system prevents the material from reabsorbing moisture. Equipped with stainless steel conveying components, an intelligent alarm system, a timer function, and optional solid-state heating control, the TCDE series is ideal for energy-efficient, high-precision injection molding.

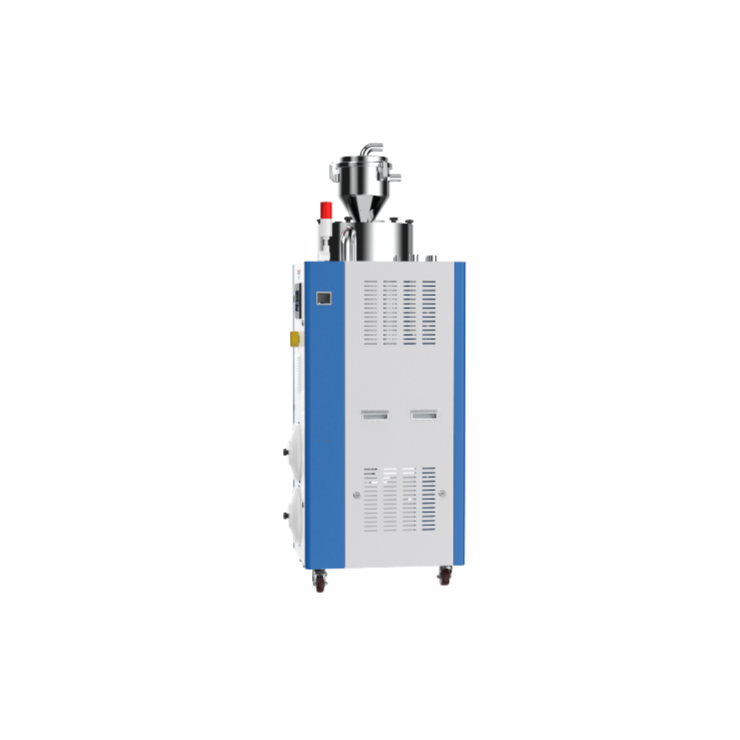

TCDH Series 3 in 1 Compact Dehumidifying Dryers

The TCDH series 3 in 1 compact dehumidifying dryer is a standard integrated solution utilizing a high-quality honeycomb rotor to provide stable, low-dew-point dry air. It combines dehumidification, drying, and conveying functions in a compact footprint, ensuring efficient material handling. The dual-cooler dehumidification system lowers return air temperature and stabilizes the dew point, while the sealed conveying circuit and shut-off valve prevent residual material and moisture from re-entering. The optical-grade model features mirror-polished stainless steel contact surfaces, making the TCDH series ideal for precision, optical, and high-quality plastic molding applications.

TDA / TDB Double Hopper 3 in 1 Compact Dehumidifying Dryer

The TDA/TDB double hopper 3 in 1 compact dehumidifying dryer is an integrated system with two hoppers, capable of drying two different plastic materials simultaneously at different temperature settings. It retains all the core functions of a standard three-in-one system—dehumidification, drying, and conveying—while saving energy and space. This design is particularly suitable for multi-material injection molding, color changes, or small-batch production, offering advantages such as flexibility, high efficiency, and low operating costs.

TDN Series Nitrogen Dryer

The TDN series nitrogen dryer is a high-end drying machine specifically developed for optical and high-precision injection molding applications. It uses high-purity nitrogen gas with a concentration exceeding 98% to dry materials, effectively reducing oxidation, yellowing, and moisture-related defects, thereby significantly improving product yield. This series of dryers is equipped with a US-made nitrogen generator, Japanese high-efficiency filters (0.3 μm × 99.99%), and a fully enclosed nitrogen circulation system, ensuring ultra-clean, ultra-low-energy operation. In addition, the nitrogen dryer helps extend screw carbonization time and reduce maintenance costs. It can also be optionally converted into a standard dehumidifying dryer, further enhancing the equipment's flexibility.