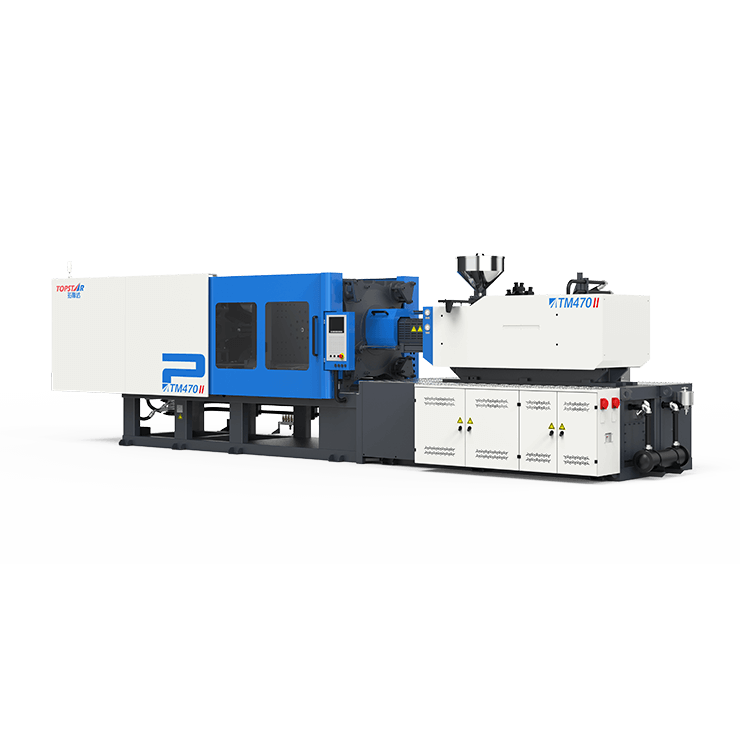

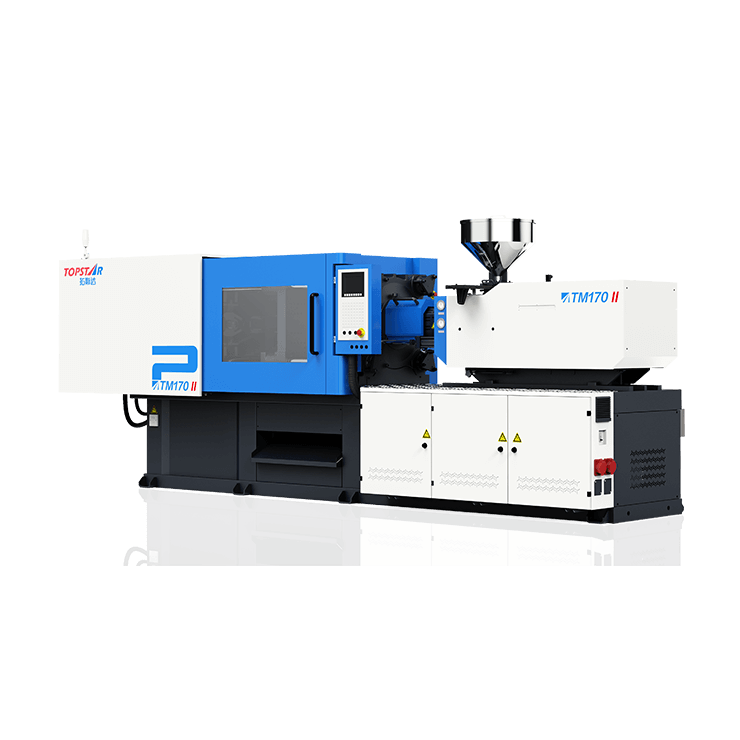

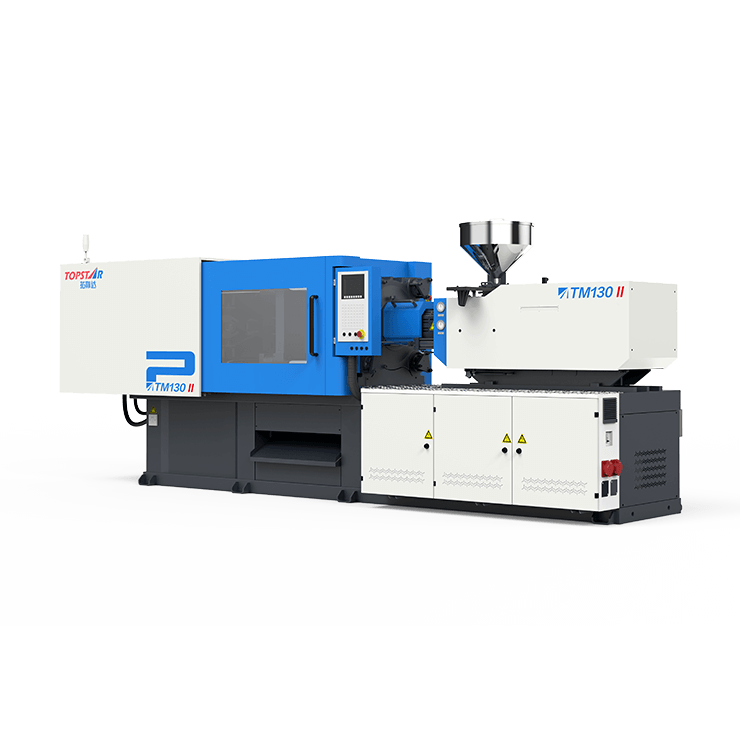

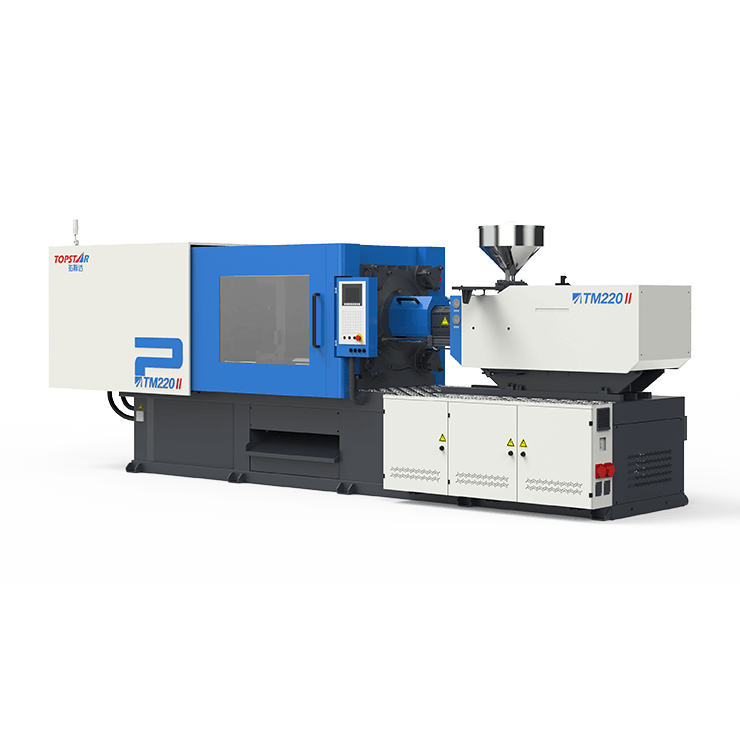

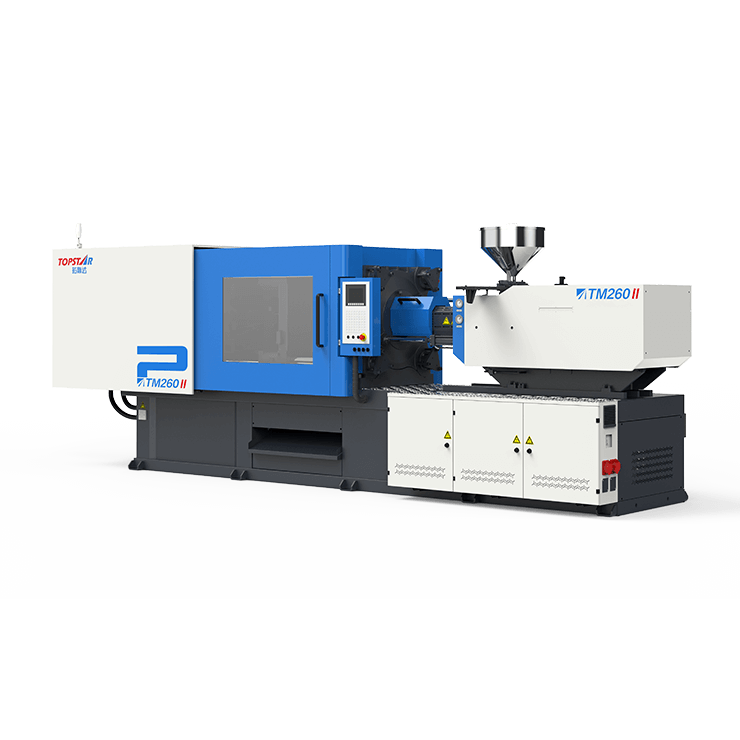

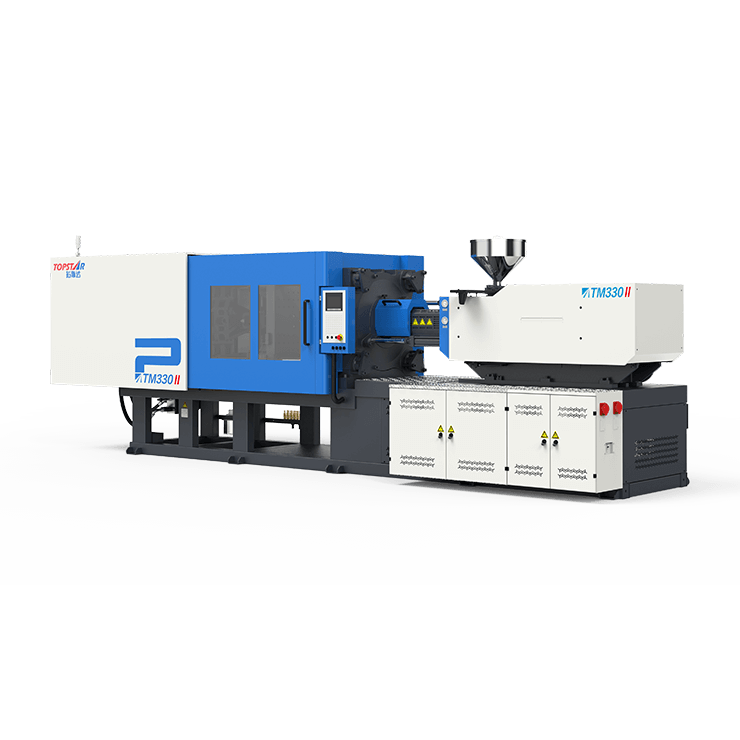

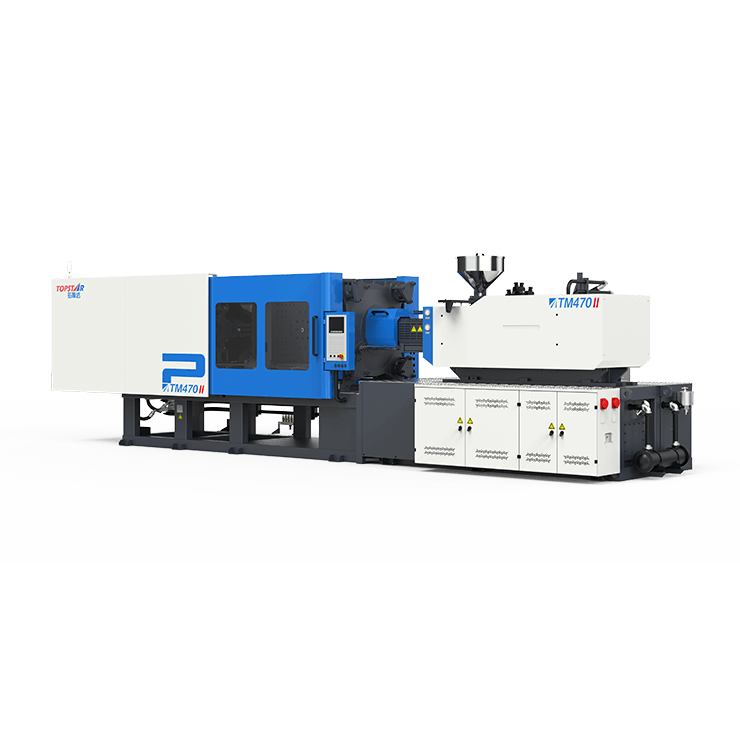

Servo-Driven Injection Molding Machine

Topstar TMII Series:Servo-Driven Injection Molding Machine(90T-470T) The servo injection molding machine combines the concept of "injection molding process integrated machine", which can realize the linkage of one control interface with multiple devices, and has the function of automatic compensation at the mold opening position, and cooperates with the injection molding robot for precise grasping. Real-time feedback of communication allows the entire injection molding process to be controlled in one piece, and can form dense plastic products with complex appearance, precise dimensions or metal inserts in one go.

Characteristics

- 1. Servo power increased by 20%, injection speed increased by 20%, screw RPM increased by 10%, and comprehensive efficiency increased by 15%.

- 2. The ejector thrust is increased by 20%, which is conducive to the demolding of connectors and plug-in products, and has a broader applicability.

- 3. The oil circuit system is fully upgraded, safe and stable, with complete functions.

- 4. The new inclined row machine toggle layout can realize a long stoke mod opening. The mold opening position accuracy is less than ± 1mm, and the mold movement is fast and stable.

- 5. The new mold adjustment structure realizes automatic and precise mold adjustment with one click.

Product Accessories

- 1. Standard KEBA controller, PHASE motor, and DELTA drive, with a self-developed control program and more precise production control.

- 2. The standard configuration of the plating screw and temperature control of the offload.higher production efficiency, and a more comprehensive application range of rubber materials.

- 3. Optimized clamping design, higher strength, and more stability.

- 4. Diagonal double carriage cylinders and linear guide, more accurate and stable injection.

- 5. Precision PVD alloy screw head set, adapt to a broader range of plasticizing requirements.

- 6. Pre-plasticizing adopts proportional back pressure control, easy to operate.Multi-stage back pressure setting can be realized, with higher precision andimproved plasticization quality.

Adequate supply of goods, available for delivery within 35 days.

Description

Fully upgraded TMII servo-drive injection molding machine (90T-470T)⇓

The second generation of Topstar servo-driven injection molding machine has been fully upgraded, integrating Topstar's "injection molding process integrated machine" concept and integrating multiple technologies. The self-developed control system realizes the communication between the injection molding machine, auxiliary machines and automation supporting equipment, reflecting the concept of control and hardware integration. Through the control interface and multi-device linkage, the injection molding process is optimized, including injection material pretreatment, plasticization, molding control, demoulding coordination and other links. Through system integration, auxiliary equipment combination and sensor technology, the best control of the temperature, speed, position, pressure, time and other parameters of the servo drive injection molding machine is achieved.

At the same time, the enhanced oil system in hardware has stronger lubrication capacity, which improves the stability and reliability of the injection molding machine. This upgrade effectively reduces operating noise, leakage and energy consumption, making it an efficient and energy-saving injection molding machine. The standard electroplated screw group used makes the injection molding process more stable and efficient. These components have excellent corrosion resistance, which helps to improve the fluidity of plastic materials and the uniformity of melts. In addition, the new mold adjustment structure can realize one-button automatic and precise mold adjustment, saving mold change time in all aspects.