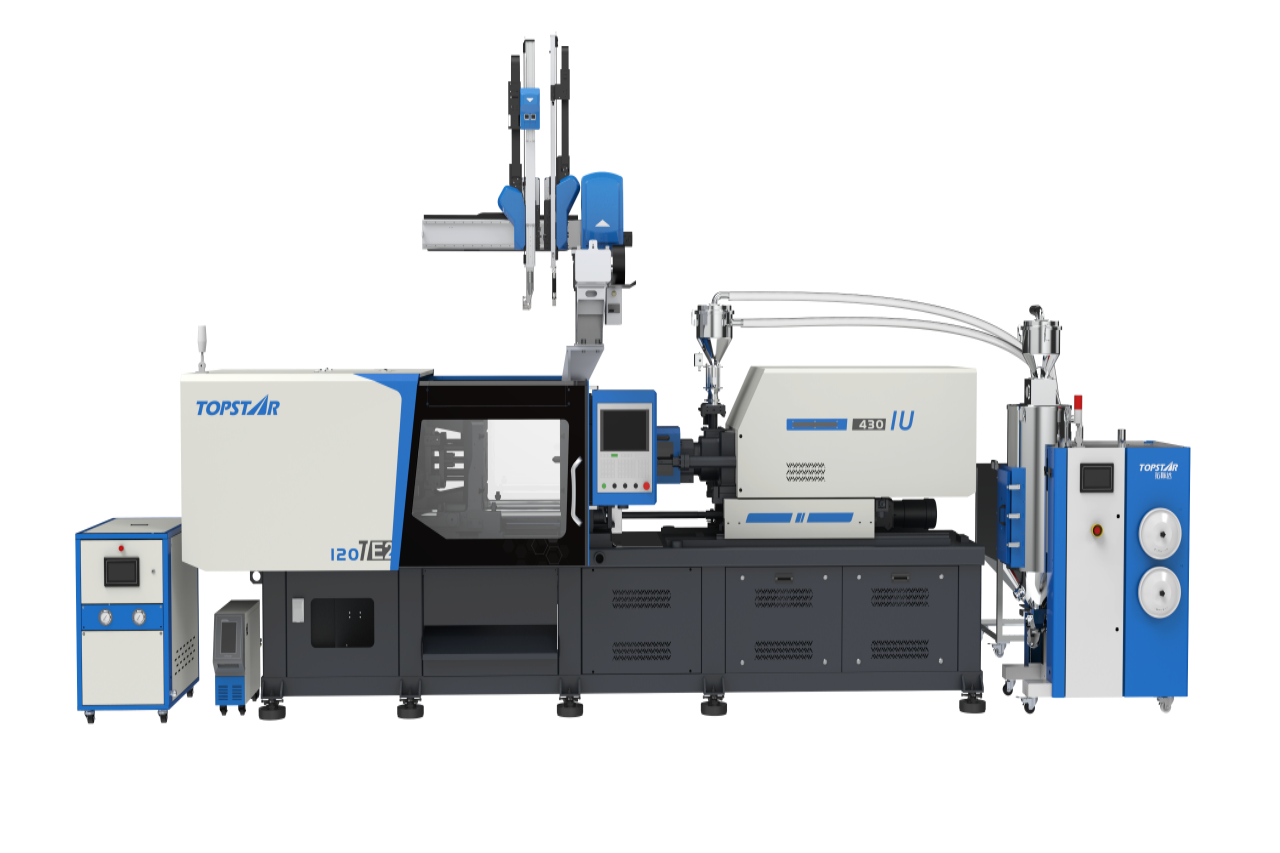

Maintaining consistent injection molding processes requires precise control of various factors, including mold temperature, injection molding machine settings, and process parameters. First, ensure precise and stable mold temperature using a mold temperature controller. Furthermore, core injection molding machines utilize fully electric machines with intelligent electric drive controls to reduce communication delays during high-speed cycles. These… Continue reading How to ensure the consistency of injection molding process?

How to ensure the consistency of injection molding process?