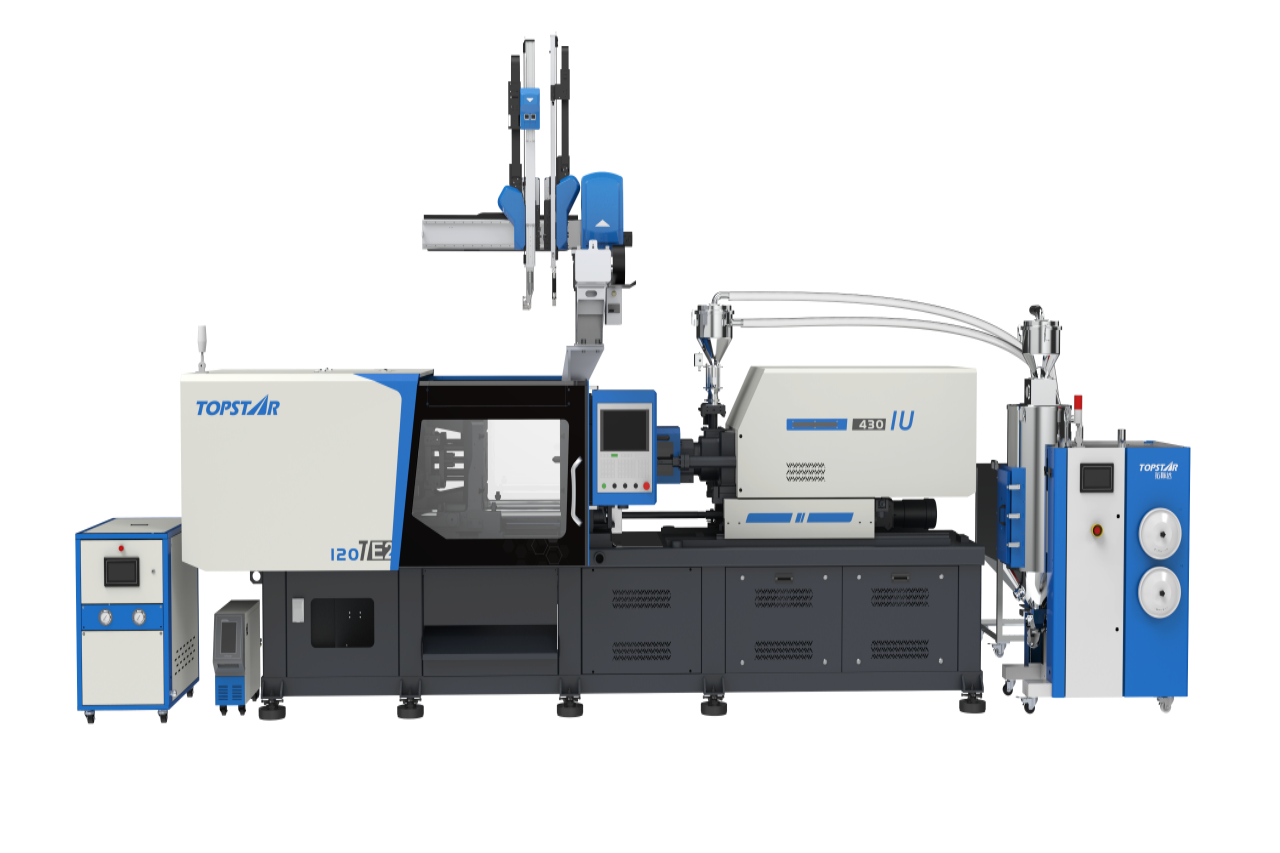

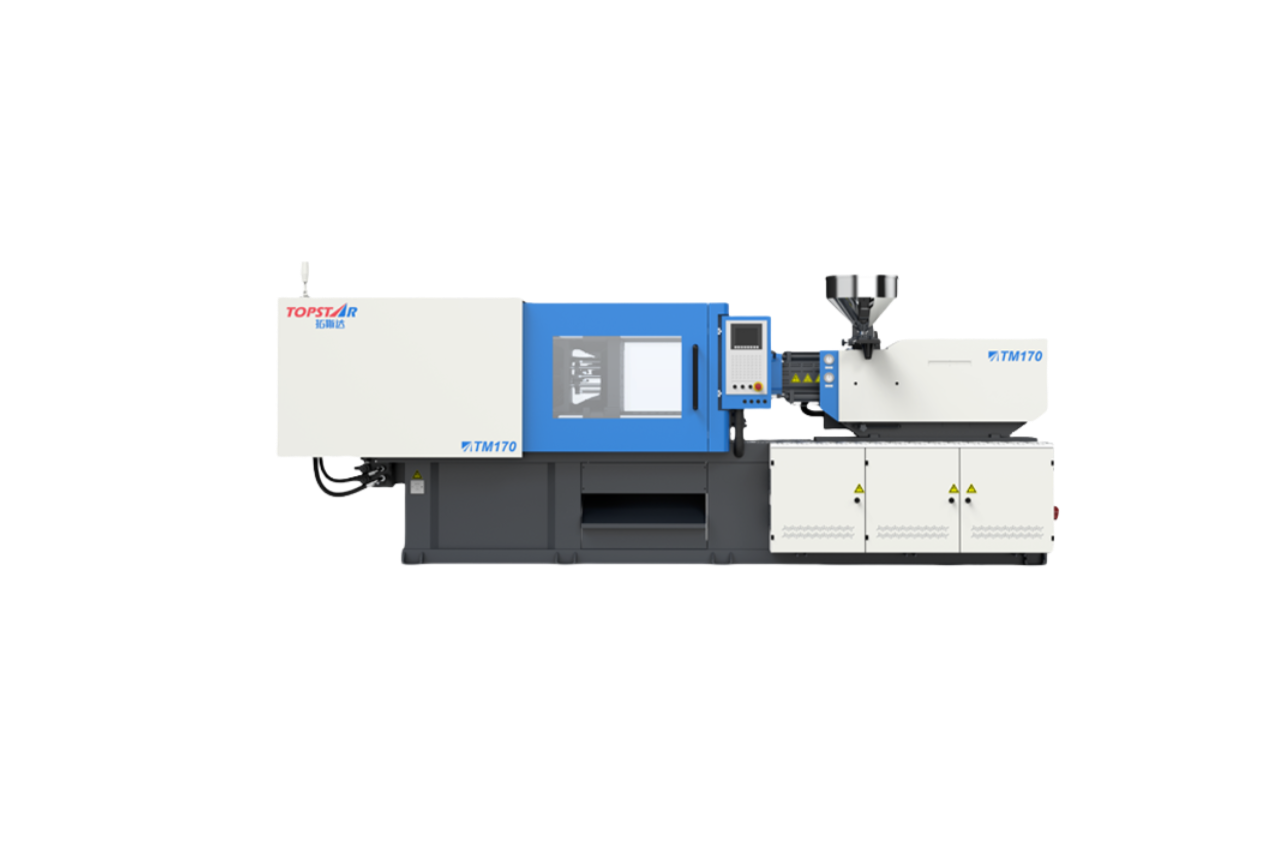

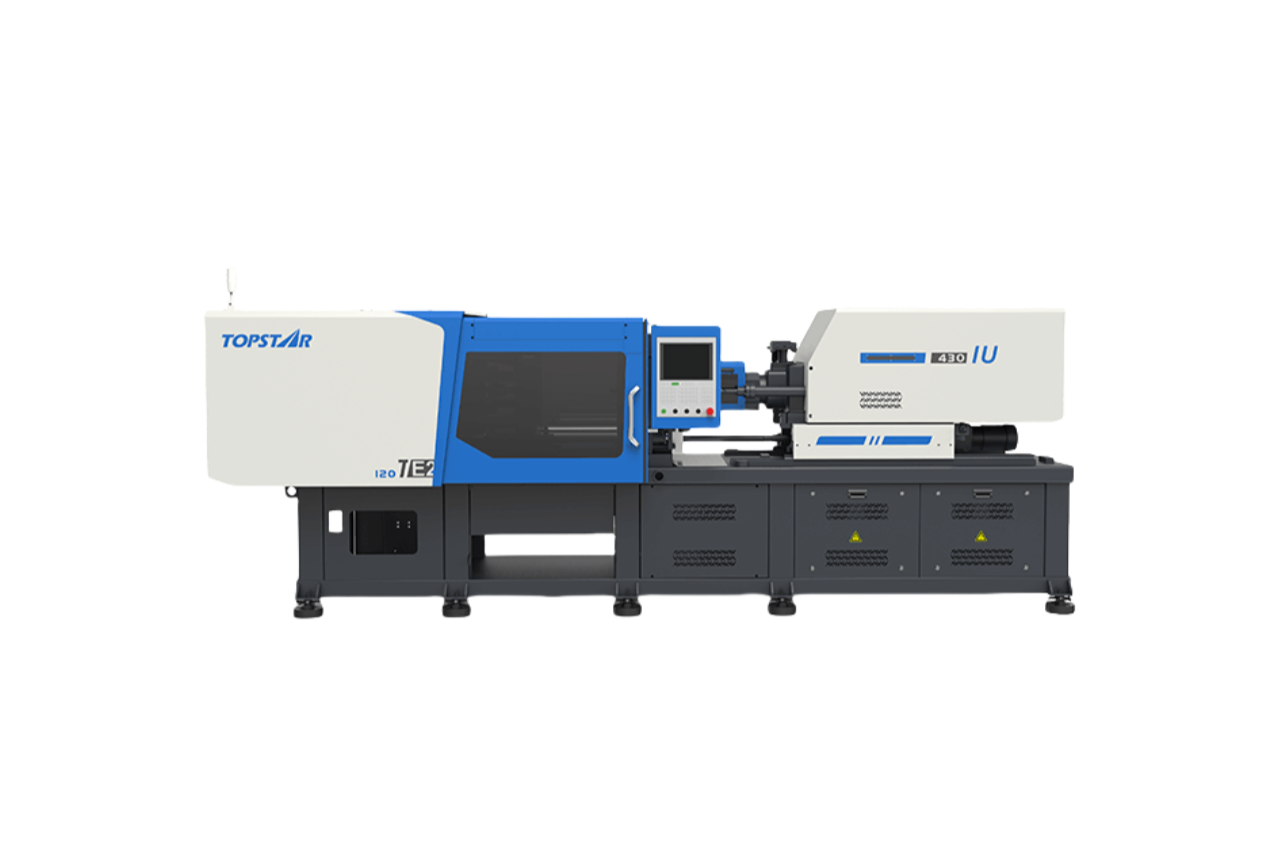

All electric injection molding machines are a more suitable solution for the injection molding of ultra-precision plastic parts. According to our customer feedback, electric drives can reduce position deviations by up to 40% compared to hydraulic systems under the same load. The intelligent servo drive architecture on the Topstar all electric injection molding machine reduces… Continue reading What kind of positioning accuracy can an all electric injection molding machine achieve?

What kind of positioning accuracy can an all electric injection molding machine achieve?