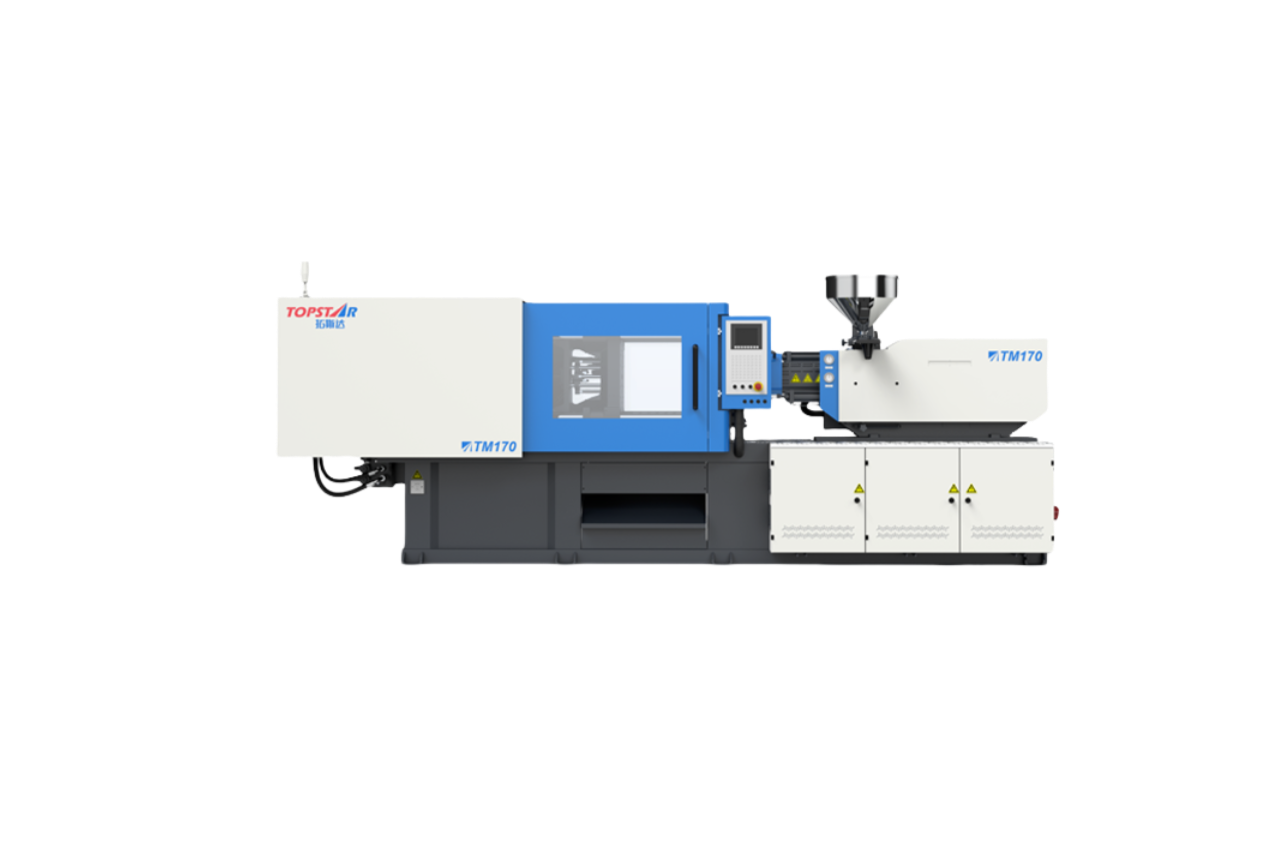

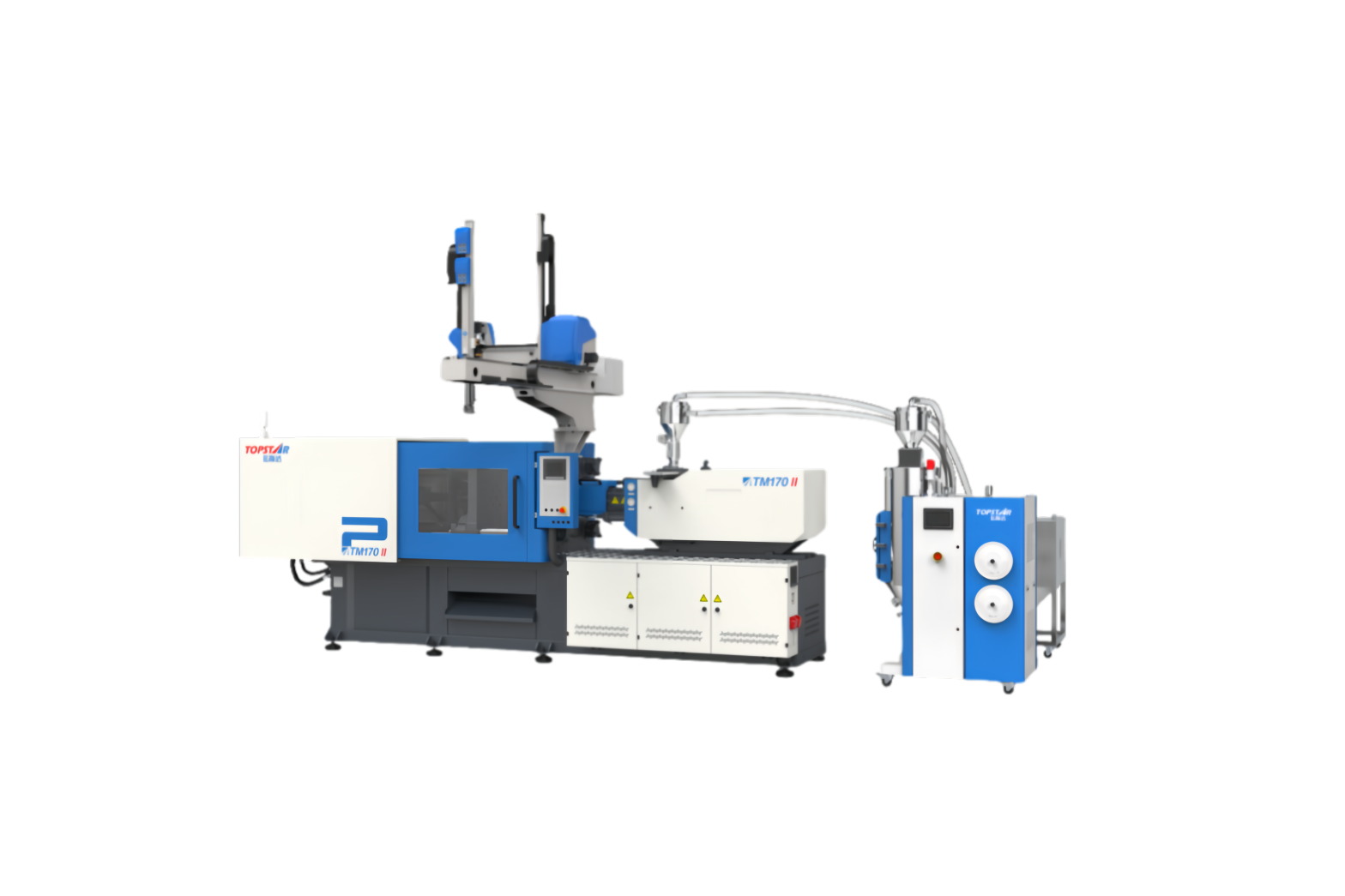

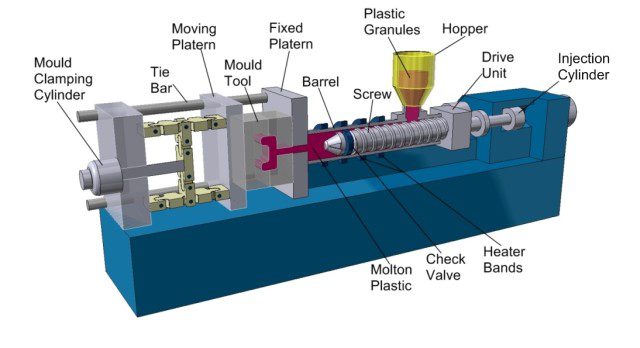

Processing high-temperature plastics requires exceptional care, demanding precise heating, controlled shearing, and reliable thermal management; otherwise, both material performance and production efficiency will be compromised. As a professional injection molding machine manufacturer, we believe that a plastic molding machine must combine the correct screw metallurgy, precise temperature control, robust mechanical design, and safe and reliable… Continue reading Can Topstar Plastic Molding Machine Handle High-Temperature Plastics for Injection Molding?

Can Topstar Plastic Molding Machine Handle High-Temperature Plastics for Injection Molding?