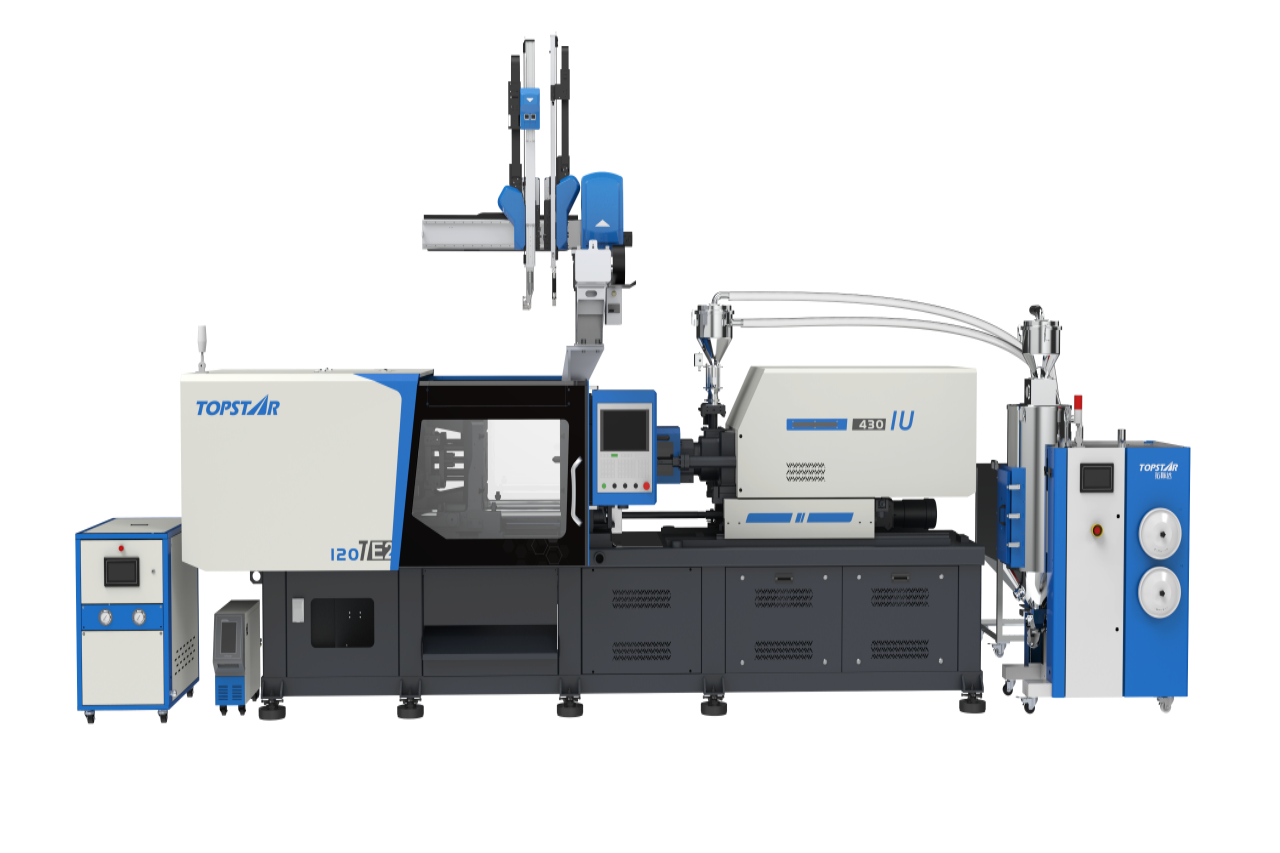

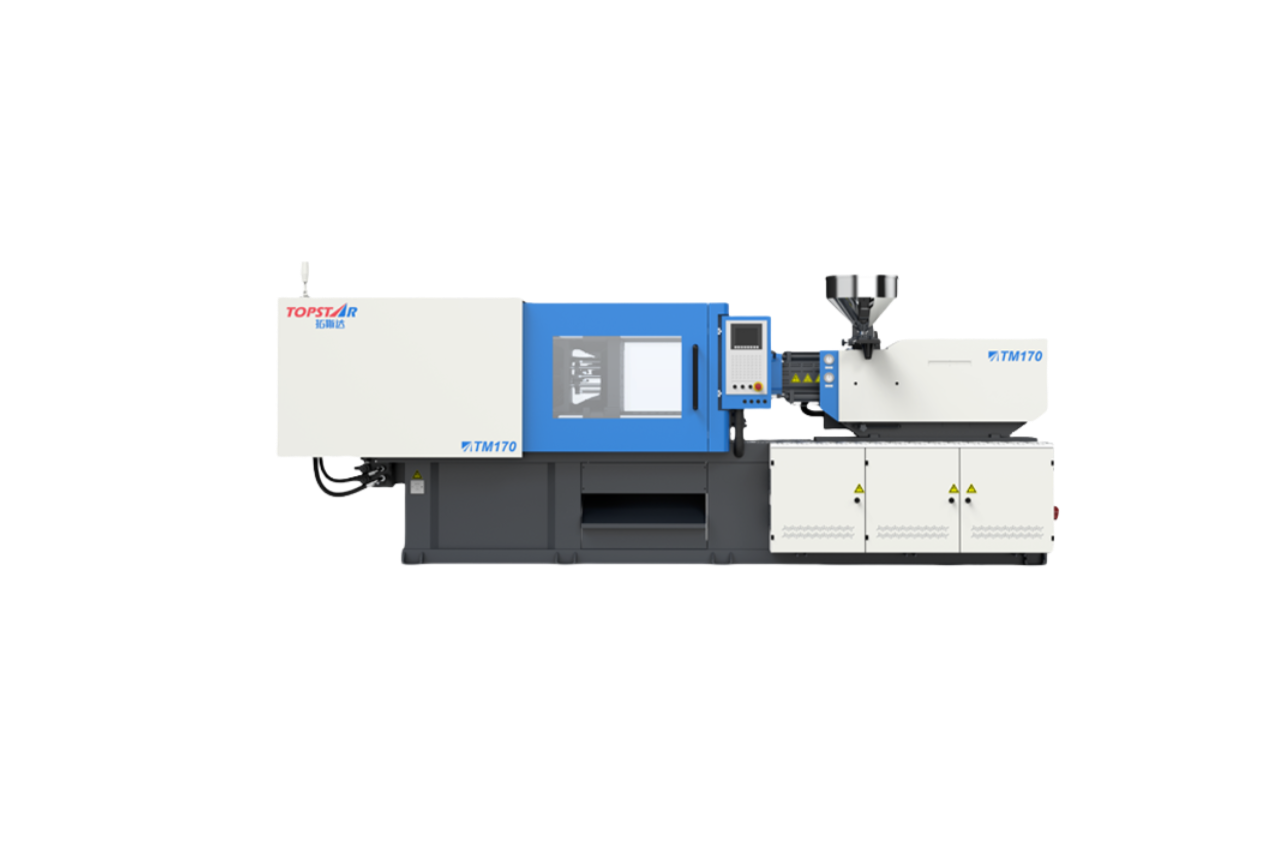

Designed for precision injection molding applications, 3-axis robots are designed explicitly for pick-and-place operations. If slight vibrations during part removal can affect quality, increase cycle time, and cause unplanned maintenance. Therefore, we integrate vibration suppression functions throughout the mechanical design and control firmware of the 3-axis robot, while also considering how to adjust the speed… Continue reading How to adjust the velocity profile of a 3-axis robot to avoid vibration?

How to adjust the velocity profile of a 3-axis robot to avoid vibration?