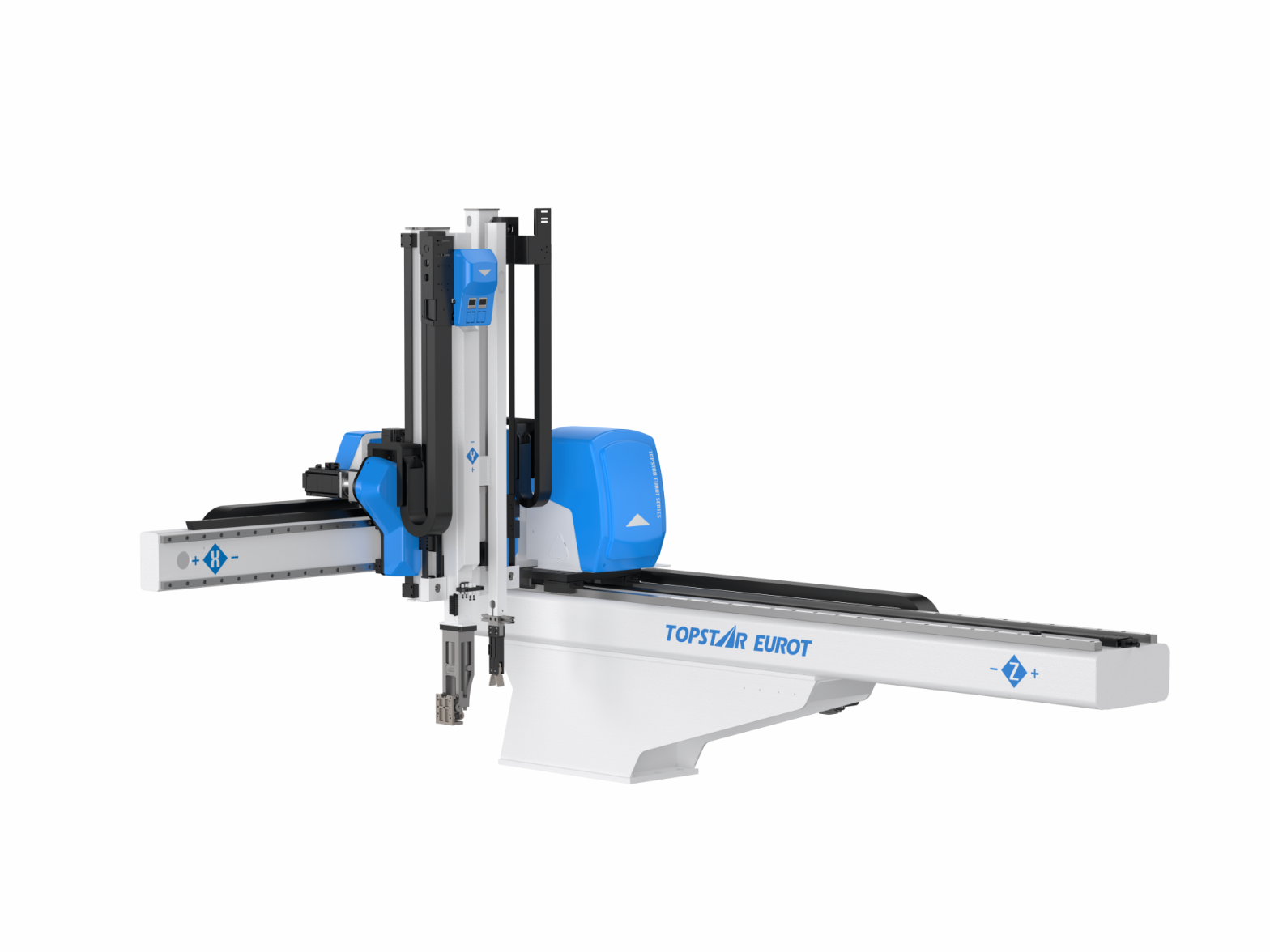

The key to selecting the right injection molding robot for your injection molding machine is to strike a balance between payload and speed. Payload refers to the maximum weight that the injection molding robot can carry, while speed refers to the speed at which the arm moves along its axis. Both factors directly affect cycle… Continue reading The trade-off between payload and speed of the injection molding robot

The trade-off between payload and speed of the injection molding robot