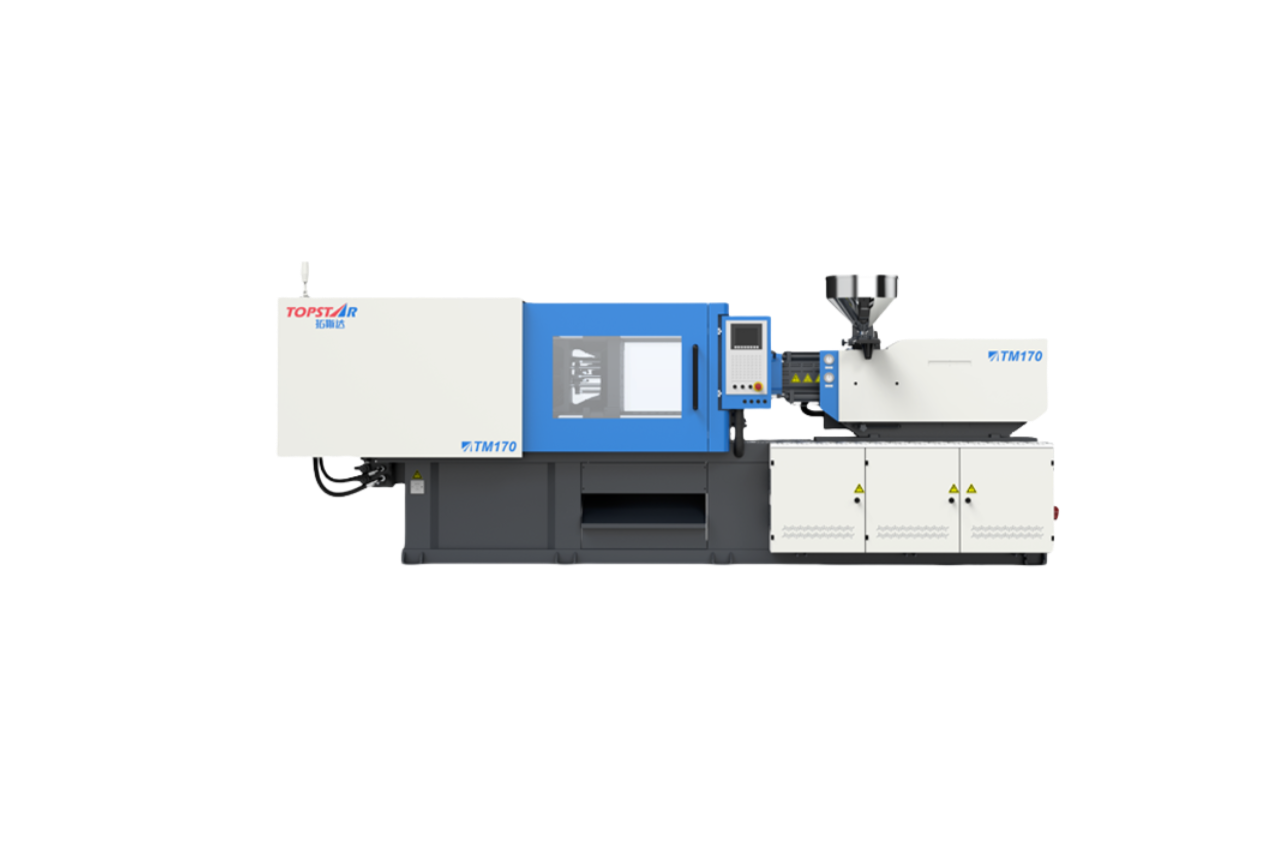

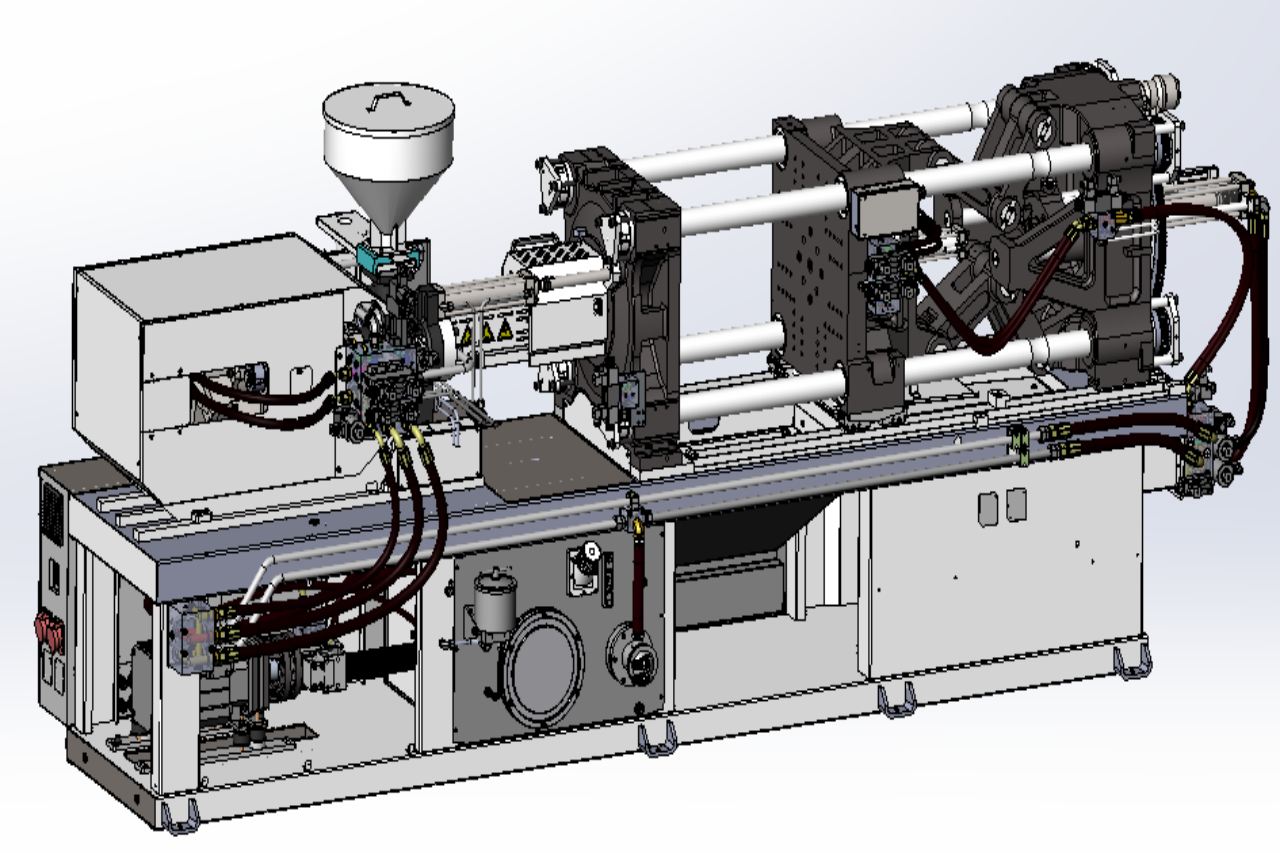

Deviation loads are often encountered when operating large injection molding machines, where unexpected lateral forces cause the injection cylinder to deviate from its center. These loads can originate from uneven melt pressure in the injection molding machine, inconsistent clamping force, or slight wear of the guide components. When the molten plastic rushes into one side… Continue reading How to avoid the deviation load of a large injection molding machine?

How to avoid the deviation load of a large injection molding machine?