News and articles from Topstar

We are committed to the innovation and application of industrial manufacturing automation.

-

2024/12/09 By: Topstar

How does water quality affect the performance of the mould temperature controller?

A mould temperature controller maintains precise mould temperature so the injection molding machine can produce high-quality, defect-free products. It regulates mould temperature by delivering water or oil through cooling channels, ensuring stable and efficient production. However, the performance of a mould temperature controller also depends mainly on the water quality used in its system, as… Continue reading How does water quality affect the performance of the mould temperature controller?

-

2024/12/06 By: Topstar

How Plastic Molding Machines Improve the Quality of Plastic Toys?

Plastic toys still occupy a large part of the global toy market. If these large and small plastic toy companies want to stand out, in addition to unique designs, they must also improve quality to make their products last longer. Their quality can vary greatly due to factors such as material consistency, mold design, and… Continue reading How Plastic Molding Machines Improve the Quality of Plastic Toys?

-

2024/12/04 By: Topstar

How can phone case maker machine improve traditional production processes?

Injection molding is one of the leading manufacturing processes for producing plastic phone cases. Traditional injection molding has served these companies well over the past few decades. However, as consumer demand for high-quality, durable, and aesthetically pleasing mobile phone accessories grows, plastic phone case manufacturers need to find ways to optimize production and improve molding… Continue reading How can phone case maker machine improve traditional production processes?

-

2024/12/02 By: Topstar

How to adjust the settings of plastic injection molding machine to improve product quality?

Injection molding is a standard manufacturing process for producing plastic products in the automotive, medical, and consumer electronics industries. The quality and precision of your products depend on the performance of the plastic injection molding machine you use and the settings of the plastic injection molding machine. A high-performance plastic injection molding machine with properly… Continue reading How to adjust the settings of plastic injection molding machine to improve product quality?

-

2024/11/27 By: Topstar

What key efficiency improvements can Injection Robots achieve?

Injection robots automatically place and grab plastic parts instead of performing manual tasks. Doing so helps simplify injection molding production lines, shorten cycle times, minimize human errors, and increase production. They improve the precision and consistency of molded parts, save more energy, and improve workplace safety. As one of Topstar’s self-developed and self-produced products, the… Continue reading What key efficiency improvements can Injection Robots achieve?

-

2024/11/25 By: Topstar

How to make the mould temperature controller reach the required temperature quickly?

Mould temperature controllers are mainly used as auxiliary machines in injection molding to provide precise temperature management for the mold. These devices can regulate the temperature of the mold to ensure consistency, improve product quality, and increase the efficiency of the production cycle. However, one of the issues mentioned in many companies’ operational feedback is… Continue reading How to make the mould temperature controller reach the required temperature quickly?

-

2024/11/22 By: Topstar

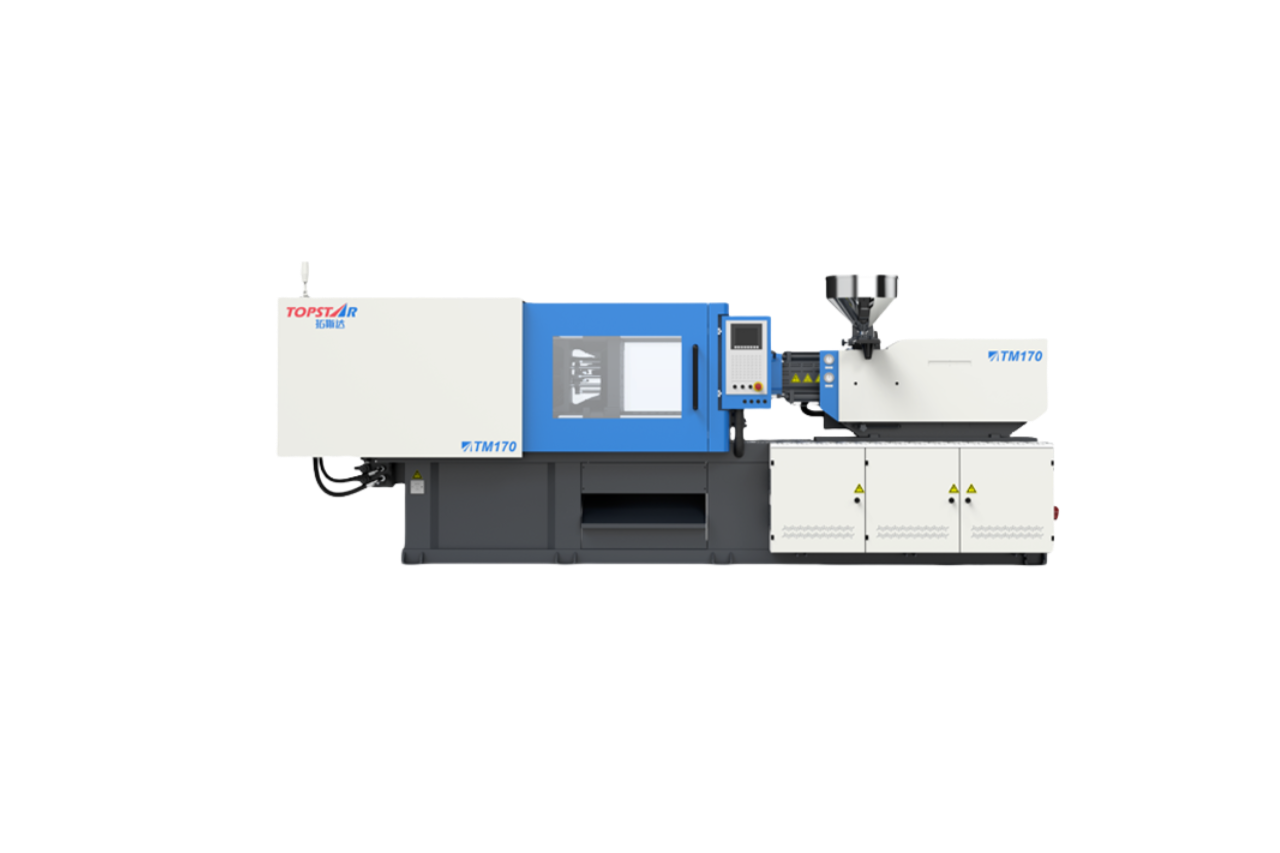

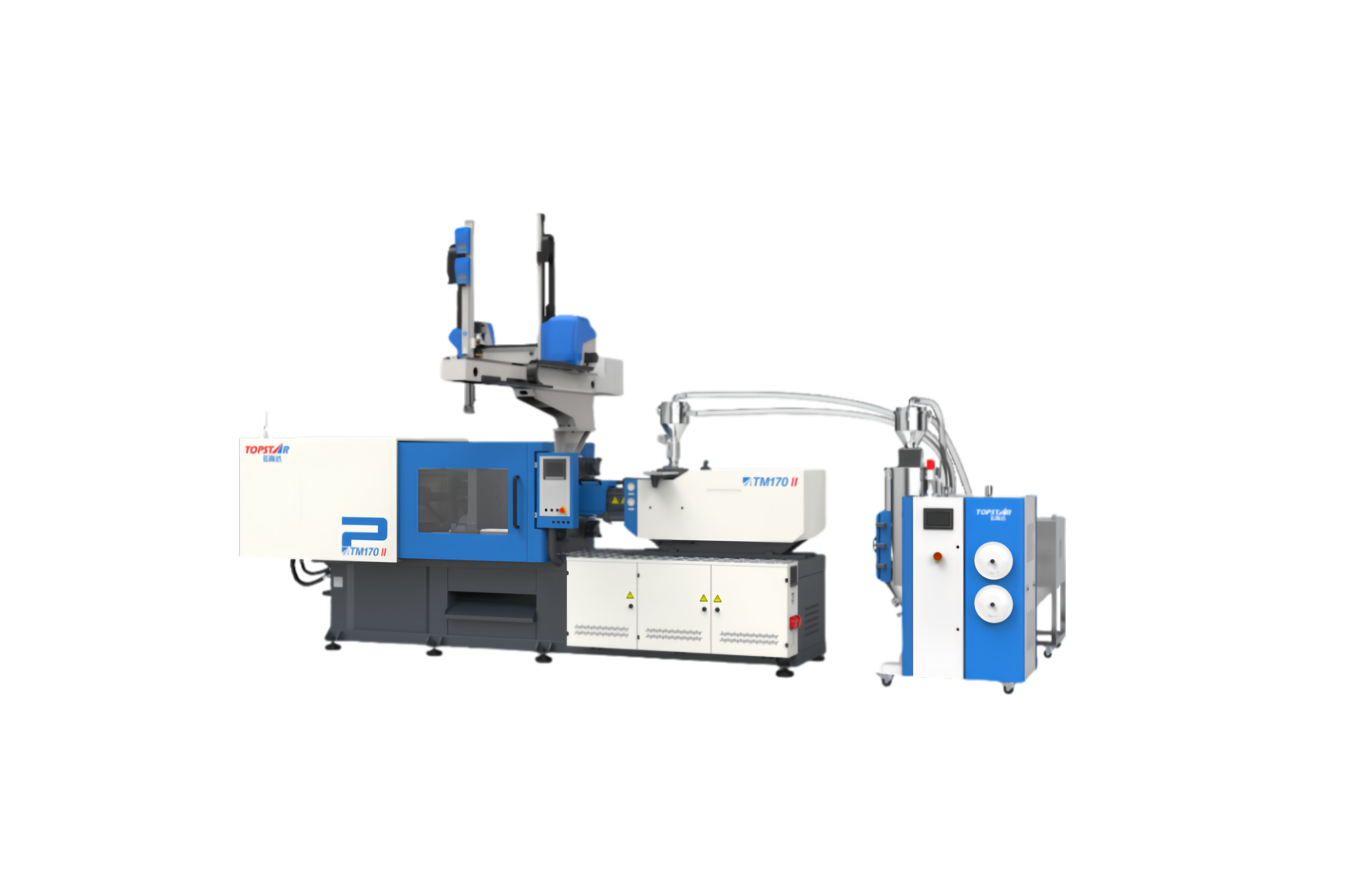

What are the benefits of equipment interconnection for horizontal injection molding machine?

In current injection molding production, the product line of peripheral auxiliary machines is very long. Technical upgrades can provide customers with excellent equipment, but they do not necessarily guarantee customers’ production results. Topstar proposed the “injection molding process machine” concept based on existing technology to simplify customer production, management, and operation. It pays more attention… Continue reading What are the benefits of equipment interconnection for horizontal injection molding machine?

-

2024/11/20 By: Topstar

Three types of injection molding machines that meet the needs of most companies

With thousands of different types and functions of injection molding machine available on the market, companies in various industries need help knowing where to start when choosing an injection molding machine that is suitable for them and can efficiently produce precise, high-quality plastic parts. Topstar supplies injection molding solutions with three self-developed core systems that… Continue reading Three types of injection molding machines that meet the needs of most companies

-

2024/11/18 By: Topstar

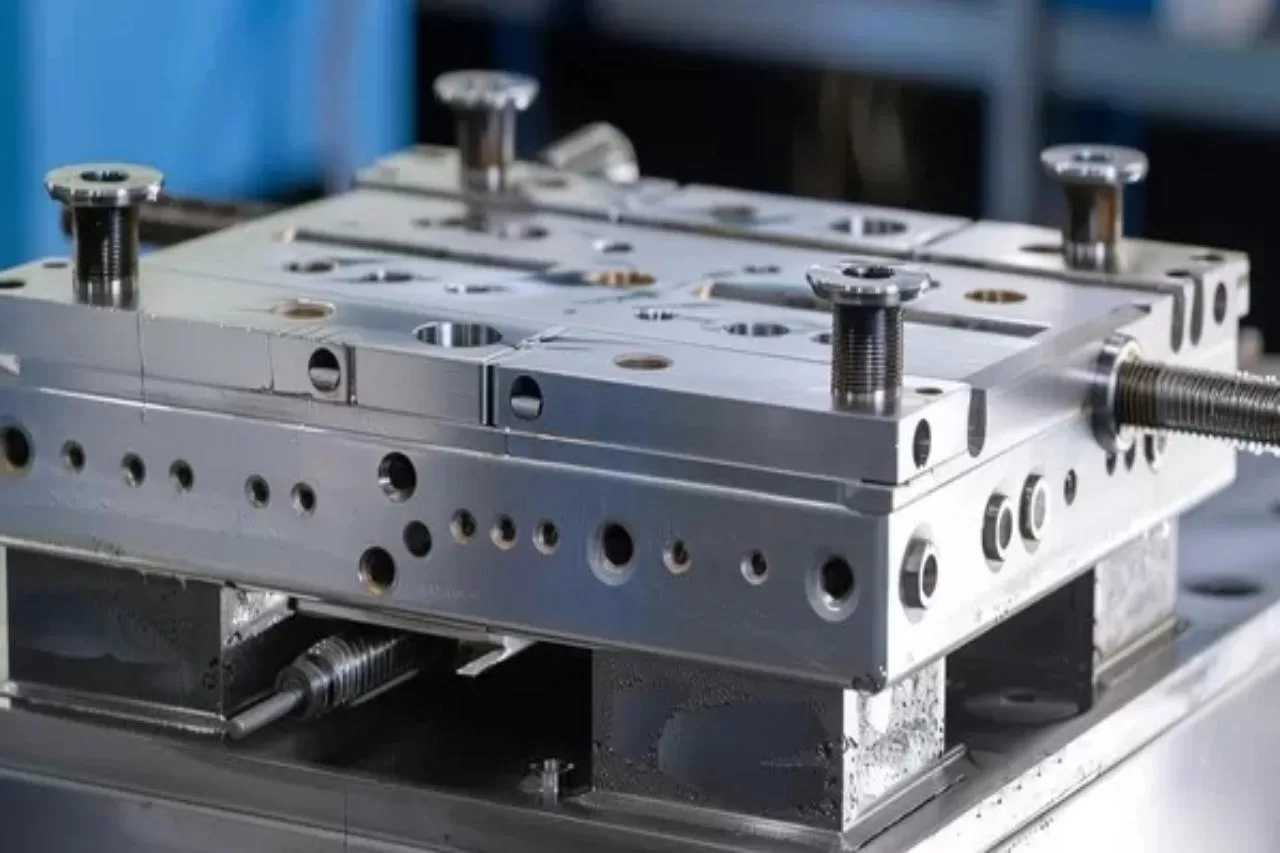

How do I prevent scaling and corrosion in mould temperature controller?

A mould temperature controller is essential equipment in injection moulding, helping to maintain consistent mould temperature to ensure part quality and operating efficiency. Most products are injected using water-type mould temperature controllers, often the most prone to common problems such as scaling and corrosion when used. It affects the performance of the equipment, resulting in… Continue reading How do I prevent scaling and corrosion in mould temperature controller?

-

2024/11/15 By: Topstar

How is the screw design of a all electric injection molding machine different from that of other machines?

In the injection molding industry, the design of the screw in the injection molding machine plays a vital role. It has a certain impact on the quality and efficiency of the molding process. The current injection molding machine market is almost all electric injection molding machines for injection molding. Their precision, energy-saving, and control capabilities… Continue reading How is the screw design of a all electric injection molding machine different from that of other machines?

-

2024/11/13 By: Topstar

How do injection molding machine manufacturer deal with high precision requirements?

In pursuit of higher precision, electric injection molding machines have gradually replaced hydraulic presses, but traditional electric injection molding machines still have a communication delay of several milliseconds. This will lead to uneven quality control when pursuing precision injection molding products. This is a problem that many customers involved in the precision industry need help… Continue reading How do injection molding machine manufacturer deal with high precision requirements?

-

2024/11/11 By: Topstar

How do mould temperature controllers manage rapid temperature changes?

During the injection molding process, the mold’s temperature change will affect the product’s quality, thereby affecting precision, especially when there is a rapid temperature change. If this situation is not managed well, it will have an adverse effect. This is a problem that many customers often need help with. After the upgrade, Topstar’s fourth-generation mould… Continue reading How do mould temperature controllers manage rapid temperature changes?