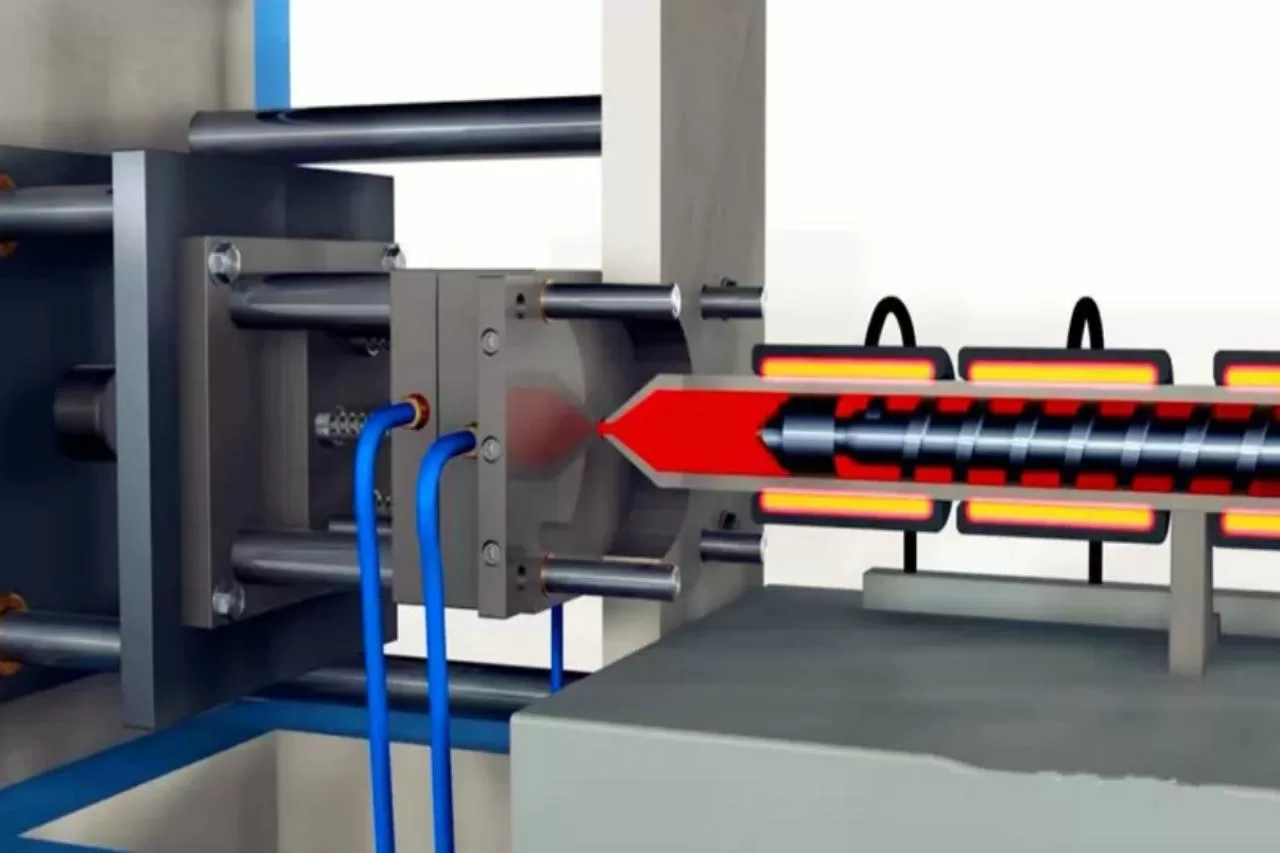

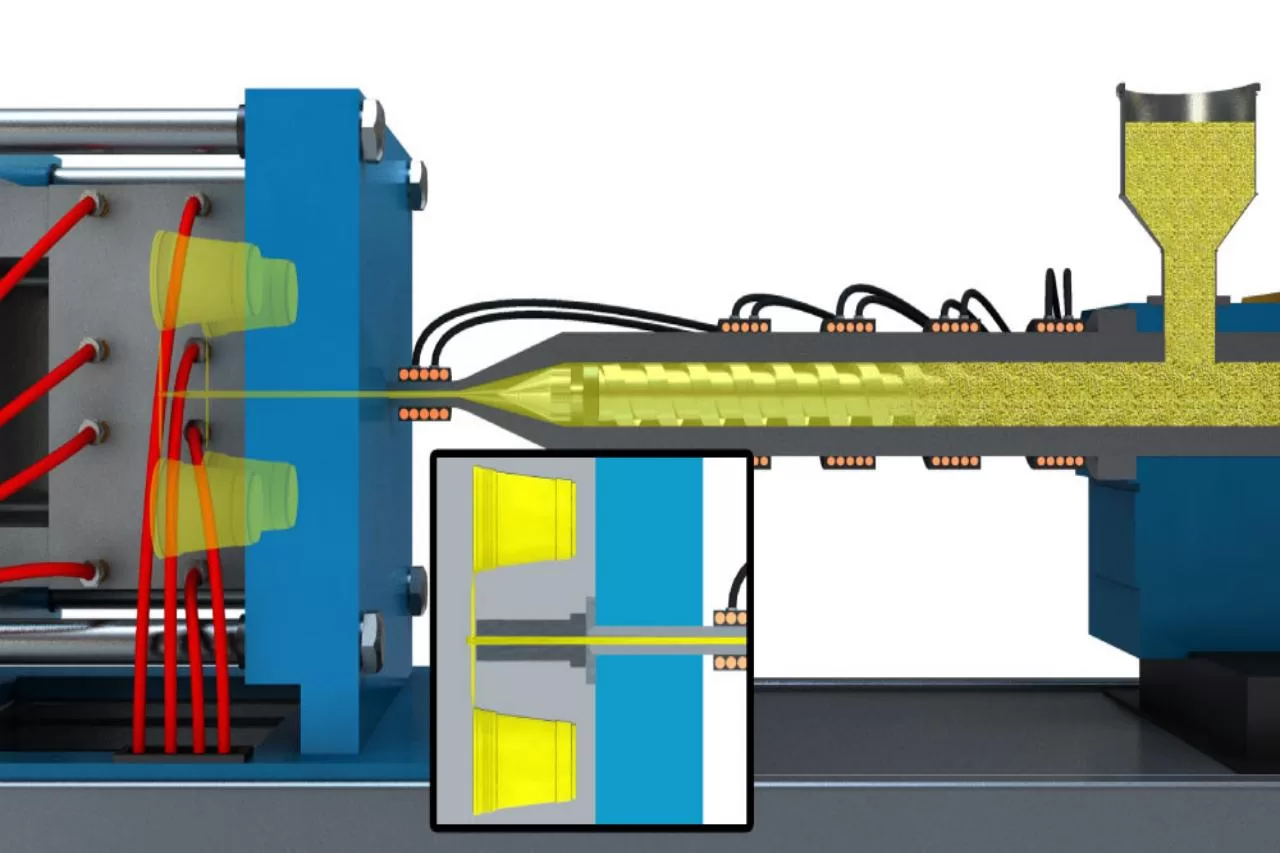

Two common mistakes are easily made when injection molding TPU/TPE: using injection pressures below 1400 kgf/cm² and using standard (non-nitrided) screws and barrels. TPU and TPE offer unparalleled flexibility and durability, but their unique flowability and abrasion resistance require specialized process control to achieve optimal results. Therefore, several key considerations must be taken into account… Continue reading Injection Molding of Flexible Materials: Precautions for TPU/TPE Processes

Injection Molding of Flexible Materials: Precautions for TPU/TPE Processes