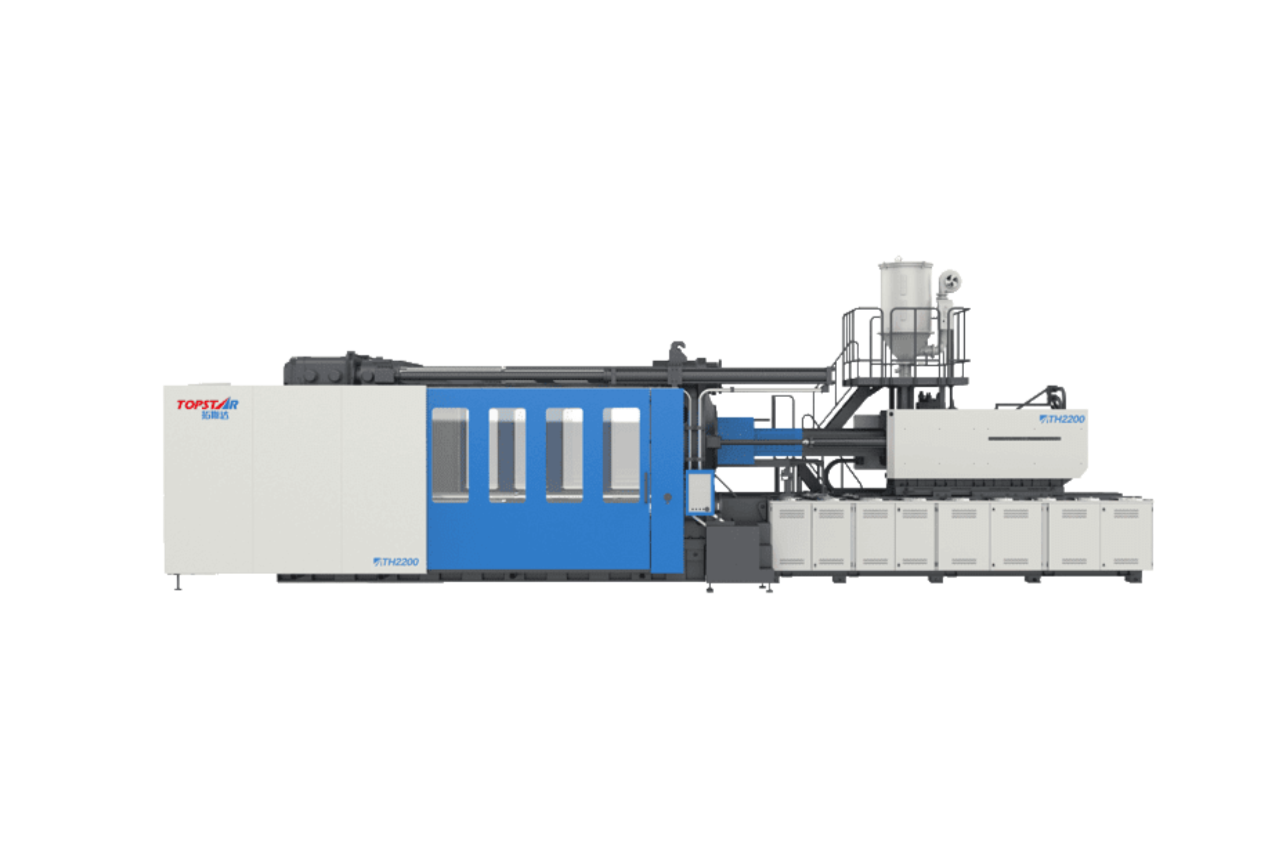

For the large injection molding machine that require high clamping forces, the clamping system has a significant impact on production accuracy, uptime, and safety. In fact, for large-tonnage, high-clamping-force injection molding machines, we utilize a multi-cylinder direct pressure clamping design. This approach expands clamping capacity without concentrating the load on a single actuator. It improves… Continue reading What kind of clamping system is needed for large injection molding machine with high clamping force?

What kind of clamping system is needed for large injection molding machine with high clamping force?