News and articles from Topstar

We are committed to the innovation and application of industrial manufacturing automation.

-

2026/03/04 By: le zhan

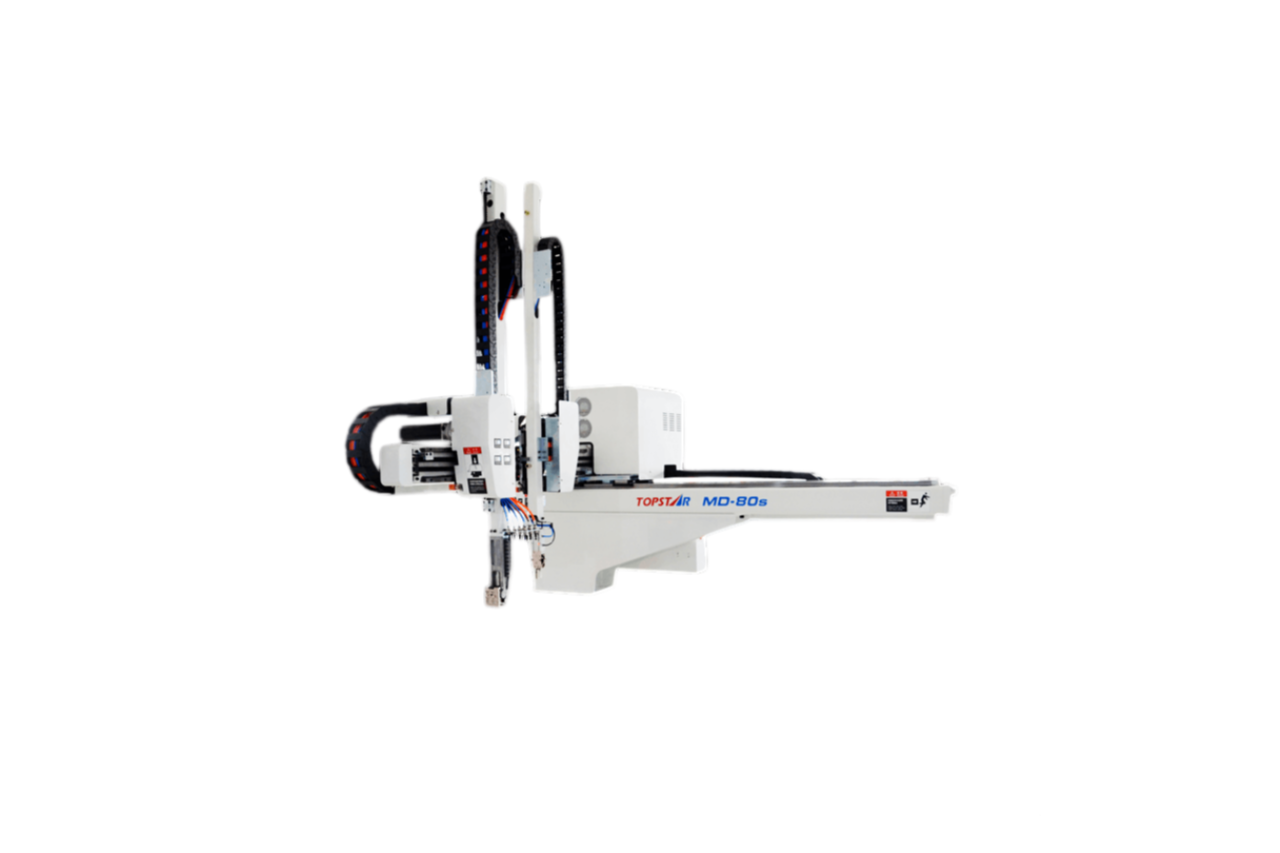

Advantages of Q235 steel arm: Enables injection molding robots to perform various non-standard insert motions

When performing non-standard insert movements, such as angular insertion, deep cavity placement, multi-step orientation, or combined handling and assembly, the mechanical structure and control system of injection molding robots require extremely high precision. In Topstar’s MDE series of robotic arms, the AC servo injection molding robot combines a servo drive platform with a main arm… Continue reading Advantages of Q235 steel arm: Enables injection molding robots to perform various non-standard insert motions

-

2026/03/02 By: le zhan

How to Calibrate the PID Controller of Topstar Injection Moulding Dryer for 1℃ Temperature Accuracy?

Precise temperature control in the injection moulding dryer ensures stable part quality and reduces scrap rates. For materials such as PA, PET, and PBT, the ±1℃ temperature control range in injection moulding dryers often determines whether dimensional tolerances or product mechanical properties meet standards. For users new to our dryers, we will explain here how… Continue reading How to Calibrate the PID Controller of Topstar Injection Moulding Dryer for 1℃ Temperature Accuracy?

-

2026/02/28 By: le zhan

How to solve the problem of blockage in the mould temperature controllers’ pipeline?

In most manufacturing plants, water contains high concentrations of calcium and magnesium ions. When these dissolved minerals are heated within the mould temperature controllers, they precipitate and gradually form scale on the heater surface, pipe walls, and mould channels. Over time, scale buildup narrows pipe diameters, reduces heat transfer efficiency, increases pump load, and ultimately… Continue reading How to solve the problem of blockage in the mould temperature controllers’ pipeline?

-

2026/02/27 By: le zhan

How can injection robots achieve automatic tracking to solve the problem of positional deviation?

Even minor positional deviations during demolding in injection robots can trigger alarms, interrupt production cycles, damage molds, or reduce part quality. These problems typically stem from inconsistent ejector positions, mismatched gripping timing, or mechanical tolerances accumulated over long production cycles. Traditional injection molding robot systems heavily rely on preset positions and fixed times, making them… Continue reading How can injection robots achieve automatic tracking to solve the problem of positional deviation?

-

2026/02/25 By: le zhan

24-hour timer function: Topstar cabinet dryer can achieve timed drying

Residual trace moisture in hygroscopic raw materials such as nylon, PET, or PBT can reduce melt quality, shorten plastic mold life, and increase waste. Topstar’s cabinet dryer solves this problem through intelligent timing, robust safety features, and precise temperature control. With a built-in 24-hour timer, adjustable airflow, PID temperature control, and a multi-layer protection system,… Continue reading 24-hour timer function: Topstar cabinet dryer can achieve timed drying

-

2026/02/20 By: le zhan

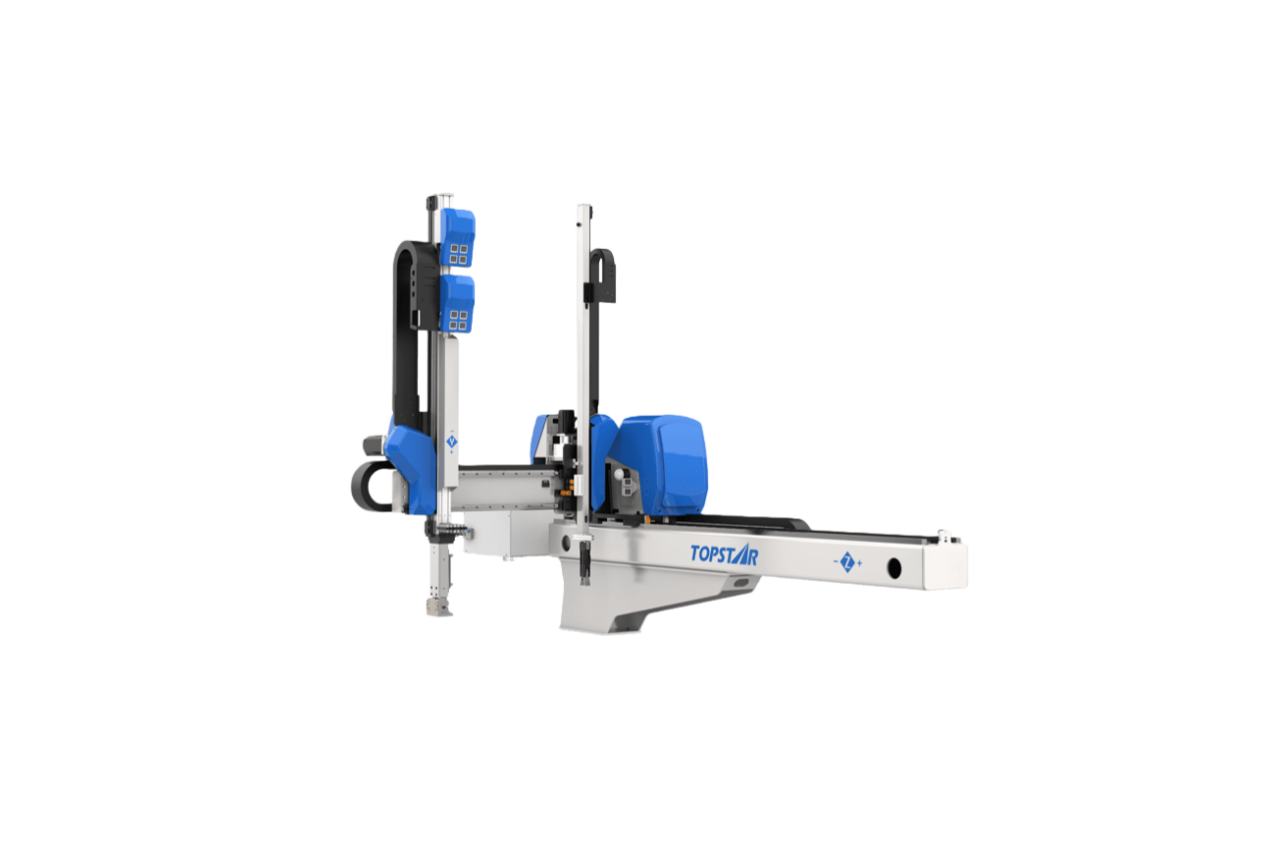

Why can Topstar’s EU series injection molding robots improve overall production efficiency?

In Topstar’s injection molding robots series, the EU series is not simply an injection molding robot, but rather a system designed to improve molding efficiency throughout the entire injection molding production process. It shortens cycle times, stabilizes downstream operations, and reduces energy consumption per part. Topstar optimizes motion control and mechanical dynamics by combining AC… Continue reading Why can Topstar’s EU series injection molding robots improve overall production efficiency?

-

2026/02/17 By: le zhan

Why can Topstar dehumidifying dryer provide a stable low dew point for injection molding?

Even trace amounts of moisture in hygroscopic resins can lead to hydrolysis, bubbles, and short shots, thus reducing the first-pass yield. Dehumidifying dryer address this problem by providing reliably low dew point drying air, ensuring that the polymer entering the injection molding machine is stable and its performance is predictable. Topstar’s dehumidifying drying solutions stand… Continue reading Why can Topstar dehumidifying dryer provide a stable low dew point for injection molding?

-

2026/02/13 By: le zhan

Stainless steel hopper: Enables contamination-free feeding for the plastic auto loader

The plastic auto loader is responsible for the physical movement, metering, and processing of plastic granules before they reach the injection molding machine. Because raw material purity directly affects melt quality, cycle stability, and finished product appearance, the design and material selection of single auto loaders are crucial. Topstar’s TAL series single auto loaders take… Continue reading Stainless steel hopper: Enables contamination-free feeding for the plastic auto loader

-

2026/02/11 By: le zhan

Molding Machine Buying Guide: Key Parameters for Precision Plastic Parts Production

The manufacturing tolerance for errors in precision plastic parts is exceptionally low. Even a deviation of a few micrometers can lead to the scrapping of an entire batch of parts and unstable assembly. Unlike traditional product manufacturing and the production of other precision plastic parts, the requirements for dimensional tolerances, repeatability, and melt behavior stability… Continue reading Molding Machine Buying Guide: Key Parameters for Precision Plastic Parts Production

-

2026/02/09 By: le zhan

Why do plastic granulators produce plastic granules of varying sizes?

In plastic recycling and injection molding, particle size affects melt uniformity, metering accuracy, drying performance, filtration performance, and ultimately, part quality. Plastic granulators produce particles of varying sizes because a multitude of interacting factors, from material properties to machine geometry and operating parameters, collectively determine particle breakage behavior during the grinding process. For plastic product… Continue reading Why do plastic granulators produce plastic granules of varying sizes?

-

2026/02/07 By: le zhan

Wide material compatibility: Screw Dosers are suitable for virgin, regrind materials, and masterbatch

For modern processors requiring precise and repeatable metering of various raw materials, Screw dosers offer a practical solution. Whether the production line is conveying virgin granules, screened regrind, masterbatch, or functional additives, a well-configured screw feeder can achieve proportional mixing with minimal operator intervention. Simply put, the device transforms the variability of the raw material… Continue reading Wide material compatibility: Screw Dosers are suitable for virgin, regrind materials, and masterbatch

-

2026/02/06 By: le zhan

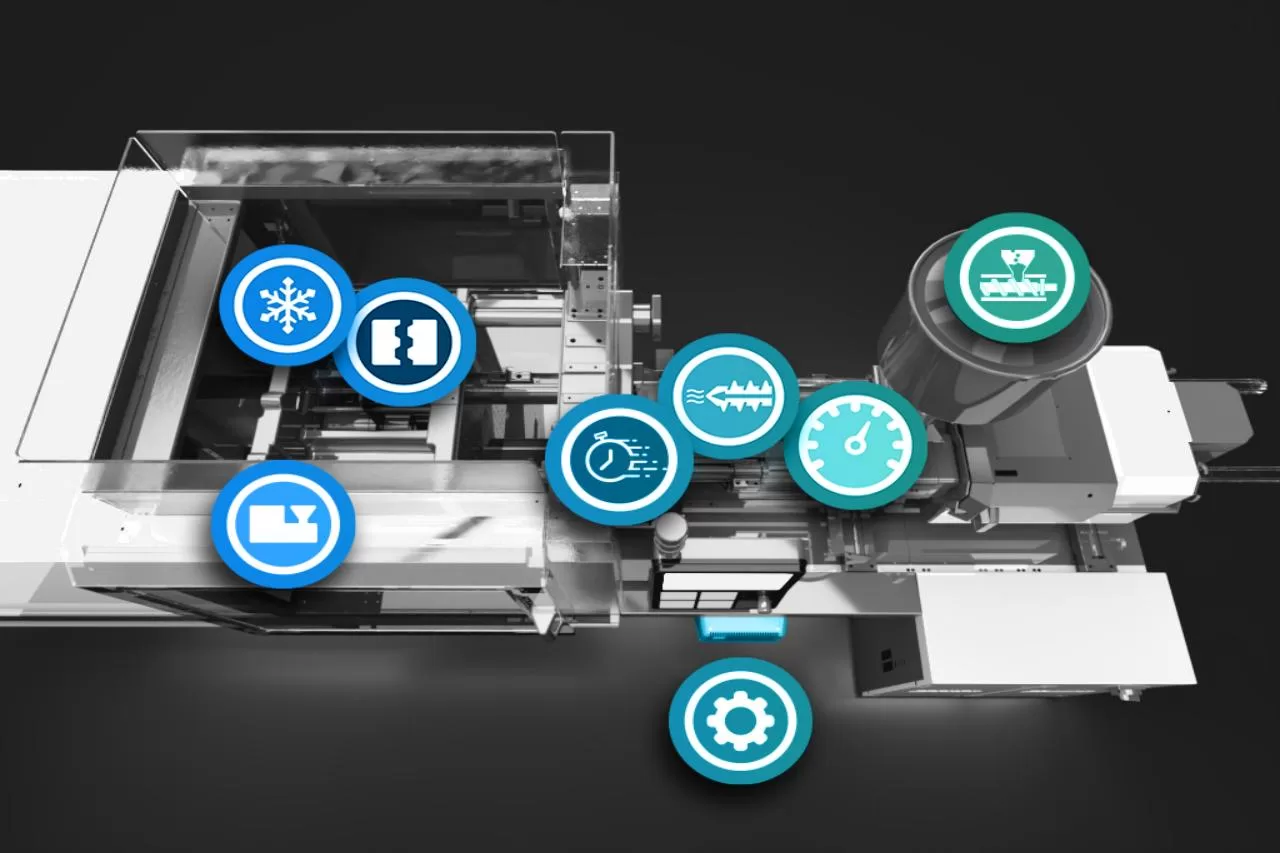

6 Essential Parameters Affecting Injection Molding Efficiency of Plastic Molding Machines

Injection molding efficiency determines a company’s competitiveness; shorter cycle times, higher first-pass yields, and predictable production efficiency directly reduce product costs. In any injection molding plant, the plastic molding machines are the core equipment, and injection molding efficiency depends on six controllable parameters that govern the physical processes of melting, filling, holding pressure, cooling, and… Continue reading 6 Essential Parameters Affecting Injection Molding Efficiency of Plastic Molding Machines