injection molding auxiliary equipment

Auxiliary Equipment

Auxiliary equipments include TDB series (3 in 1 Compacts), mold temperature controller, automatic feeding system, and other series. The main uses cover dehumidification and drying of raw materials, raw material transportation, mold temperature control, injection molding production, secondary processing of products, etc. Use imported components to improve product performance. The machine adopts microcomputer control, which consumes less energy and is easier to operate.

Products

Auxiliary Equipment

Products

Auxiliary Equipment

- High Performance

- Reliability

- Durability

- Universally Applicable

Highly integrated

Precise and Efficient

Under a unified control system, Topstar’s auxiliary equipment is highly integrated and can be interconnected with injection molding machines. Users can directly access auxiliary equipment operating data on the injection molding machine, making the operation more convenient.

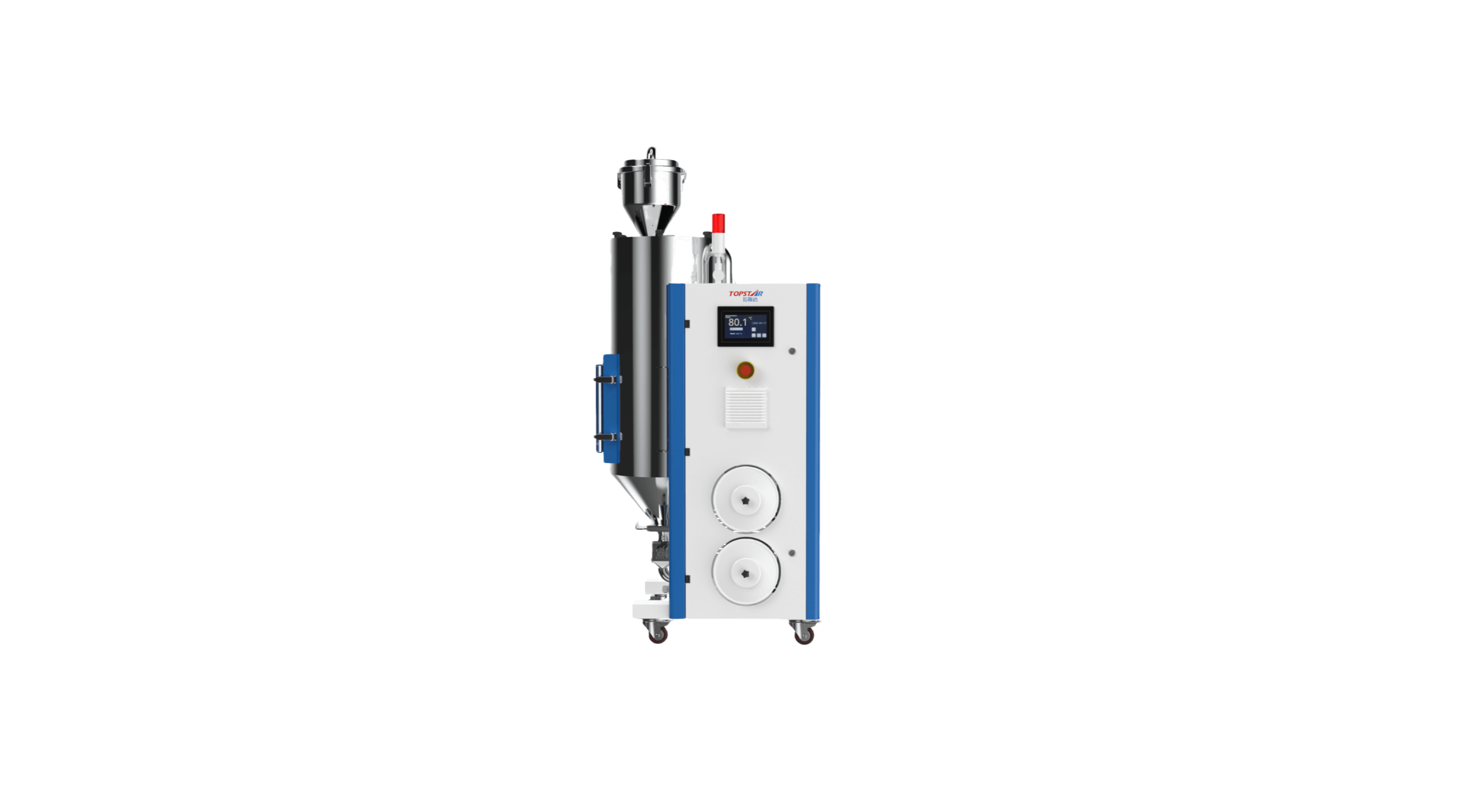

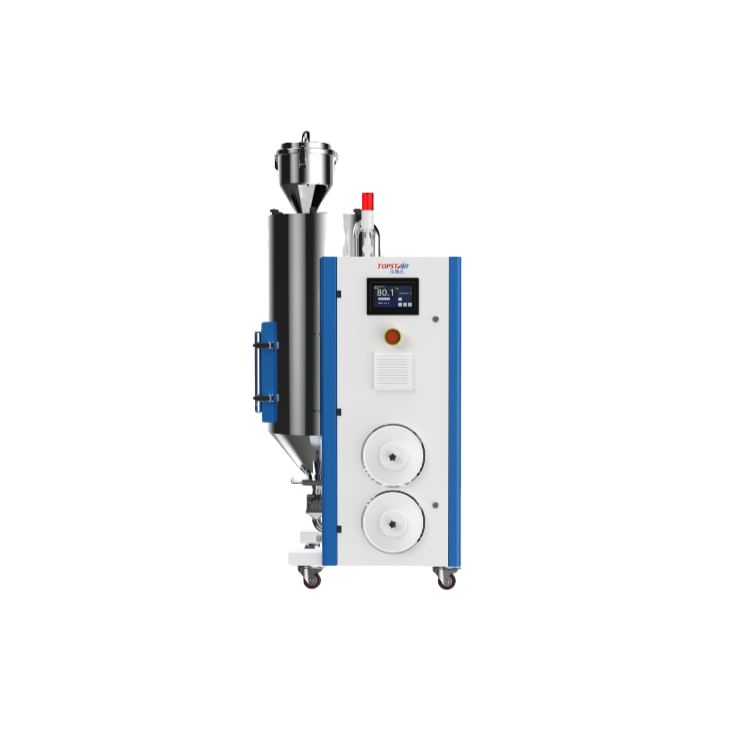

Drying and Dehumidifying System

Designed specifically for injection molding and plastics processing applications, our dehumidifying dryers provide stable humidity control, efficient drying performance, and contamination-free material handling. All Topstar dehumidifying dryer series feature the following core characteristics:

- Precise Temperature and Humidity Control:

Most models utilize a PID temperature control system to ensure precise drying temperature and stable dew point performance, improving molding consistency and product quality.

- Efficient Drying and Energy-Saving Design:

Optimized hot-air circulation, honeycomb-rotor dehumidification, a closed-loop air system, and insulated drying hoppers significantly reduce energy consumption while accelerating drying speed.

- Integrated Safety Protection System:

Comprehensive protection measures—including over-temperature protection, motor overload protection, phase loss protection, pressure monitoring, and intelligent alarms—ensure safe, reliable, and continuous operation.

- Modular, Compact, and Space-Saving Structure:

Many models feature a 3-in-1 integrated design (dehumidification, drying, and conveying) or a compact layout, saving floor space and simplifying installation and maintenance.

- User-Friendly Operation and Intelligent Control:

Clear digital displays, alarm codes, timer scheduling, recipe memory, and optional communication interfaces support easy operation and smart factory integration.

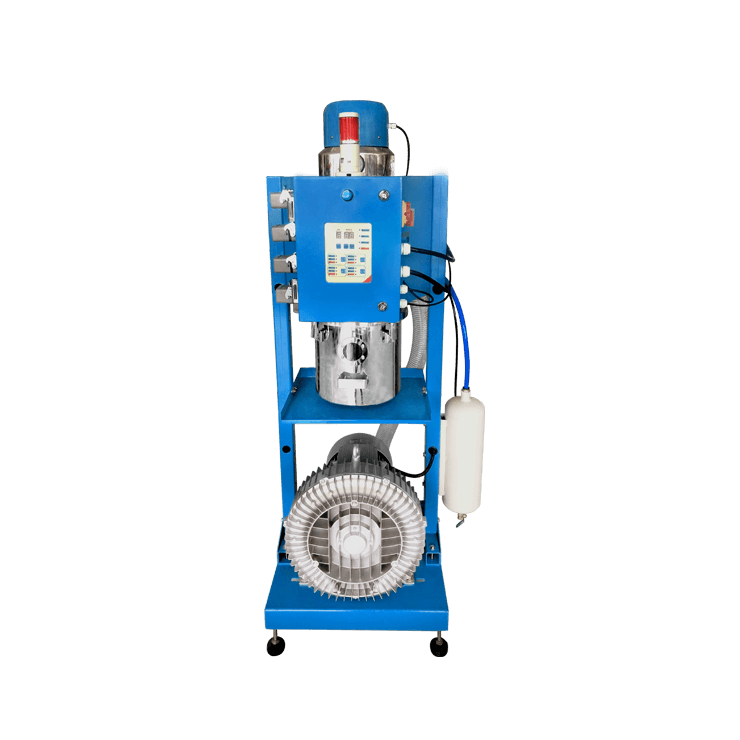

Feeding and Conveying System

Material conveyors provide clean, stable, and efficient material handling in injection molding. These conveyors feature stainless steel construction, intelligent control systems, reliable motor protection, and efficient filtration, ensuring contamination-free feeding, reduced downtime, and consistent molding quality, while offering flexible configurations and strong compatibility.

- Clean and Contamination-Free Material Handling:

Stainless steel contact parts ensure no material contamination, sealed conveying and efficient filtration reduce dust and impurities, and maintain the stability of injection molding material quality.

- Reliable Motor Protection and Long Service Life:

Built-in motor protection and overload protection ensure stable operation under continuous production conditions, reducing downtime and maintenance costs.

- Intelligent Control and Safety Alarms:

Equipped with a material shortage alarm device to ensure uninterrupted production, fault and overload indicators provide real-time status feedback, and microprocessor or microcomputer control ensures precise operation.

- Efficient Dust Removal and Easy Maintenance:

High-efficiency filters, with dust-removal functionality or cyclone-assisted design, feature independent or detachable dust-collection structures that are easy to disassemble for quick cleaning and daily maintenance.

- Flexible Configuration and Strong Compatibility:

Compatible with different hoppers and injection molding machines, with optional configurations for long-distance conveying, recycled materials, or mixed materials, suitable for new materials, recycled materials, and mixed material applications.

Metering and Mixing Machines

Metering and mixing machines provide precise material metering, uniform mixing, and stable feeding for injection molding processes. Topstar’s metering and mixing solutions are compatible with a wide range of applications, including virgin and recycled materials and color masterbatches, helping manufacturers improve efficiency, reduce costs, and achieve reliable, repeatable production.

- High-Precision Material Control:

Enables precise metering and mixing of virgin resins, recycled materials, masterbatches, and additives to ensure consistent product quality.

- Stable and Reliable Operation:

Designed for continuous industrial use, equipped with intelligent control systems, motor protection, and alarm functions to minimize downtime.

- Stainless Steel Material Contact Design:

All material contact parts are made of stainless steel to prevent contamination and meet high cleanliness requirements.

- Modular and User-Friendly Structure:

Modular, detachable design facilitates cleaning, quick material changes, and simplified maintenance.

- Flexible Configuration and Strong Compatibility:

It can be integrated with injection molding machines, extruders, automatic feeders, and centralized feeding systems.

- Cost-Effective and Material Saving:

Precise proportion control reduces material waste, supports the controlled use of recycled materials, and lowers overall production costs.

Water chillers

Water chillers used in injection molding provide stable and precise temperature control from 5°C to 35°C. All models feature high-quality compressors, advanced heat-exchange designs, and intelligent temperature-control systems for rapid cooling, low energy consumption, and long-term, reliable operation.

- Precise and Stable Temperature Control:

All Topstar water chillers offer a wide, stable temperature control range of 5°C–35°C, ensuring consistent cooling performance for injection molding machines, molds, and auxiliary equipment.

- High-Efficiency and Energy-Saving Design:

Equipped with high-quality compressors, optimized evaporators and condensers, and intelligent control systems, Topstar chillers maximize heat exchange while minimizing energy consumption.

- Reliable Industrial-Grade Components:

All models utilize high-quality brand compressors, durable water pumps, and corrosion-resistant materials, ensuring a long service life, stable operation, and reduced maintenance costs in continuous industrial use.

- Advanced Heat Exchange Technology:

Optimized condenser and evaporator designs, such as shell-and-tube, microchannel, or coil structures, improve heat transfer efficiency and enhance overall cooling performance.

- High-Performance Water Circulation System:

Built-in high-flow, high-pressure centrifugal water pumps ensure a stable water supply, strong cooling capacity, and reliable circulation for molds and injection molding equipment.

- Comprehensive Safety Protection System:

All chillers are equipped with multiple safety protection devices, including over-temperature protection, high- and low-pressure protection, overload protection, phase-sequence protection, and anti-freeze protection, ensuring safe and uninterrupted operation.

Granulating and Recycling System

Topstar granulation and recycling systems are high-efficiency plastic granulators specifically designed for injection molding recycling applications, enabling the rapid, clean, and cost-effective reuse of sprues, runners, defective parts, and plastic scraps. Designed for materials such as PC, ABS, nylon, PBT, and other engineering plastics, Topstar granulators provide uniform regrind quality, reduce material oxidation, and improve recycling efficiency.

- High-Efficiency Plastic Recycling:

These plastic granulators are designed specifically for injection molding applications, efficiently recycling sprues, runners, rejects, and plastic scraps, significantly reducing raw material waste and production costs.

- Wide Material Compatibility:

Suitable for a variety of plastics, including PC, ABS, nylon, PBT, and other engineering plastics, ensuring stable recycling performance across different injection molding applications.

- Uniform Regrind Quality:

Optimized cutting structure and precision blade alignment technology ensure uniform particle size and low dust content, guaranteeing reliable regrind quality suitable for injection molding.

- Durable Industrial-Grade Blade Design:

Equipped with high-quality alloy or tool steel blades, offering excellent wear resistance, longer service life, and lower maintenance frequency.

- Low Noise and Energy-Efficient Operation:

Low-speed or optimized-speed granulation design minimizes noise, vibration, and energy consumption, creating a safer and more efficient production environment.

Mold temperature controller

Topstar mold temperature controllers feature standard functions such as rapid heating, stable temperature control, and low leakage rates, meeting the industry’s demand for intelligent, digital upgrades. They effectively solve temperature control problems in injection molding production, achieving temperature control accuracy of ±0.1℃, a 10% improvement in temperature control efficiency, and a 40% increase in service life.

- Wide Temperature Control Range:

Supports both water-based (120°C–180°C) and oil-based (160°C–320°C) mold temperature controllers, meeting a wide range of injection molding and high-temperature processing requirements.

- High-Precision Temperature Control:

Equipped with advanced PID control algorithms and high-resolution sensors, ensuring stable and accurate mold temperature control, thus guaranteeing consistent molding quality.

- 7-Inch Touchscreen Control System:

Most models are equipped with an intuitive 7-inch HMI touchscreen, providing real-time temperature, pressure, and flow monitoring, easy operation, and clear data visualization.

- Higher Production Efficiency:

Rapid heating, stable circulation, and intelligent temperature control help shorten cycle times and improve overall molding productivity.

- Suitable for Intelligent and Digital Manufacturing:

Advanced monitoring functions and intelligent control systems support smart factory integration and modern injection molding automation.

Training for Installation and Operation Correctly

Topstar Service

We have a comprehensive after-sales training system. To address potential issues and ensure optimal operation, we provide you with the necessary training resources for installing and operating the packaging machine.

- Instructions for Use – Installation Steps and Operating Precautions

- Video demonstration of installation and debugging

- On-site training – additional service fee required

Technical Support

Whether your business is located in Europe, North America, or the Middle East, we provide global services, and our experts are on call to provide technical support services through video calls or on-site assistance. Services include:

- First installation and debugging of equipment

- Daily debugging and maintenance

- Emergency fault assistance

- Equipment optimization services

The Machinery Industry Professionals

- Customized Requirements

- Solutions

- Professional Packaging

- Delivery & Installation

- 24H Technical Support

The Topstar team delivered the Water & Electric Engineering project efficiently and perfectly in a complex environment with an urgent delivery schedule.

LUXSHAREICE

From EEA series to TE series, we see the continuous pioneering and innovative spirit of Topstar in the field of injection molding machines.

Dme Udaykumar

The robotic arms were installed and ran smoothly, which greatly improved our production efficiency!

Thai A-Tech

Listen To The True Voice Of Customers

We sincerely appreciate that more than 15,000 customers have witnessed the TOPSTAR growth and long-term supports.