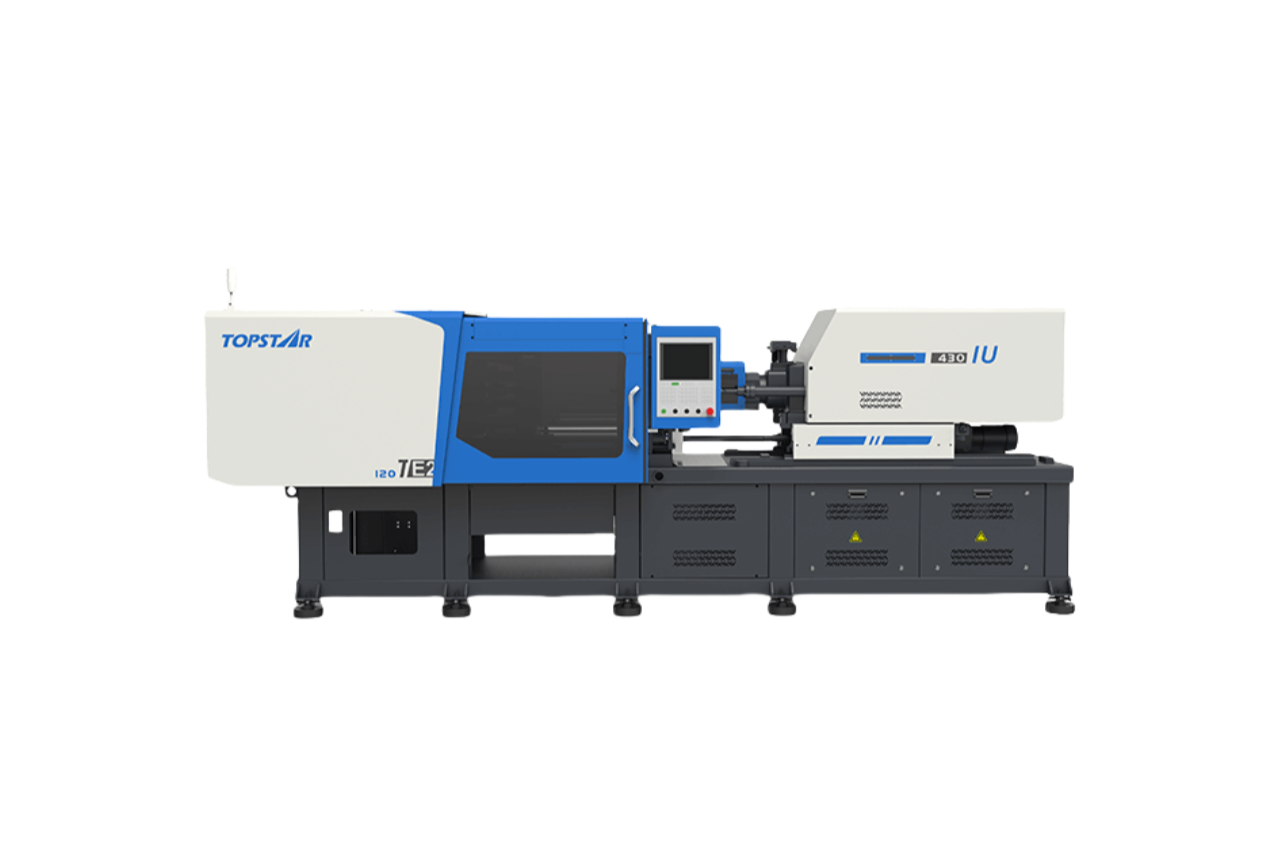

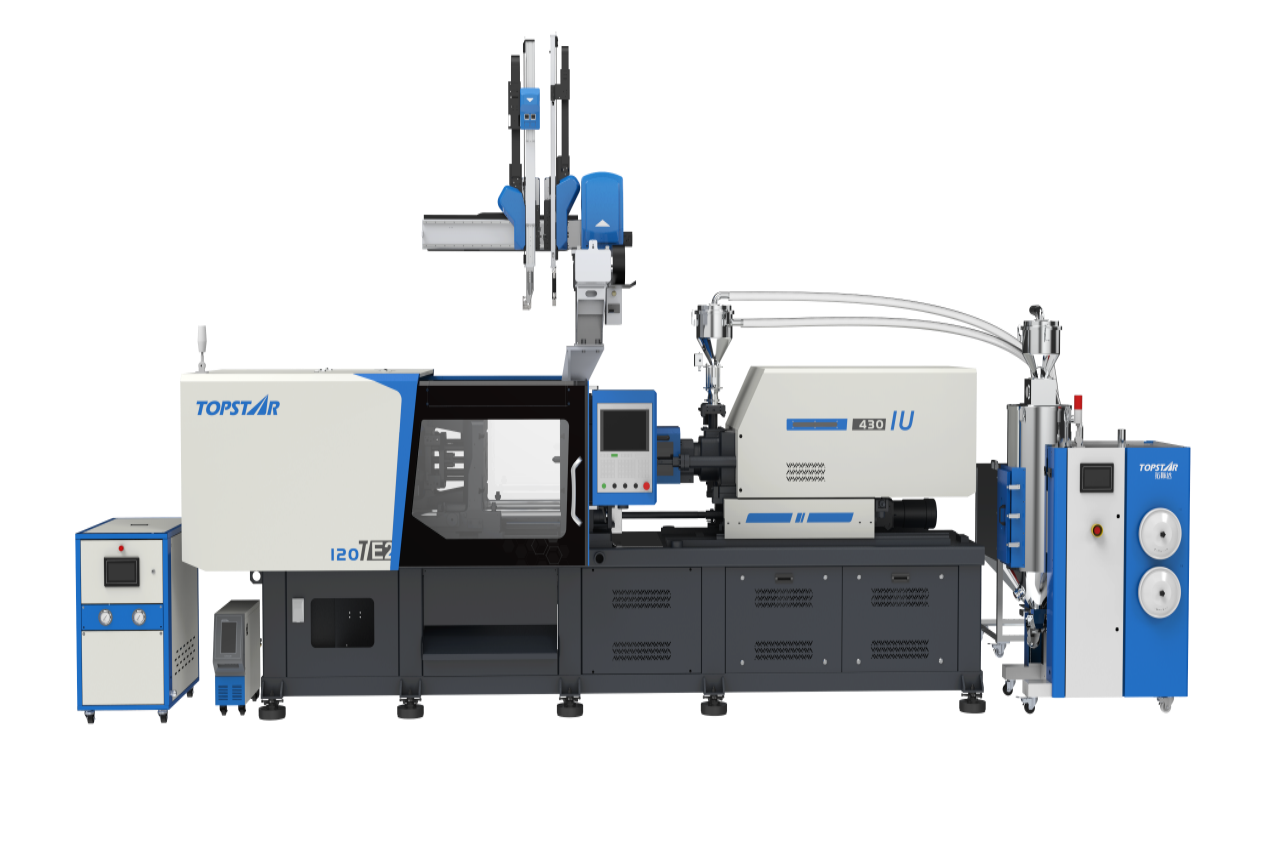

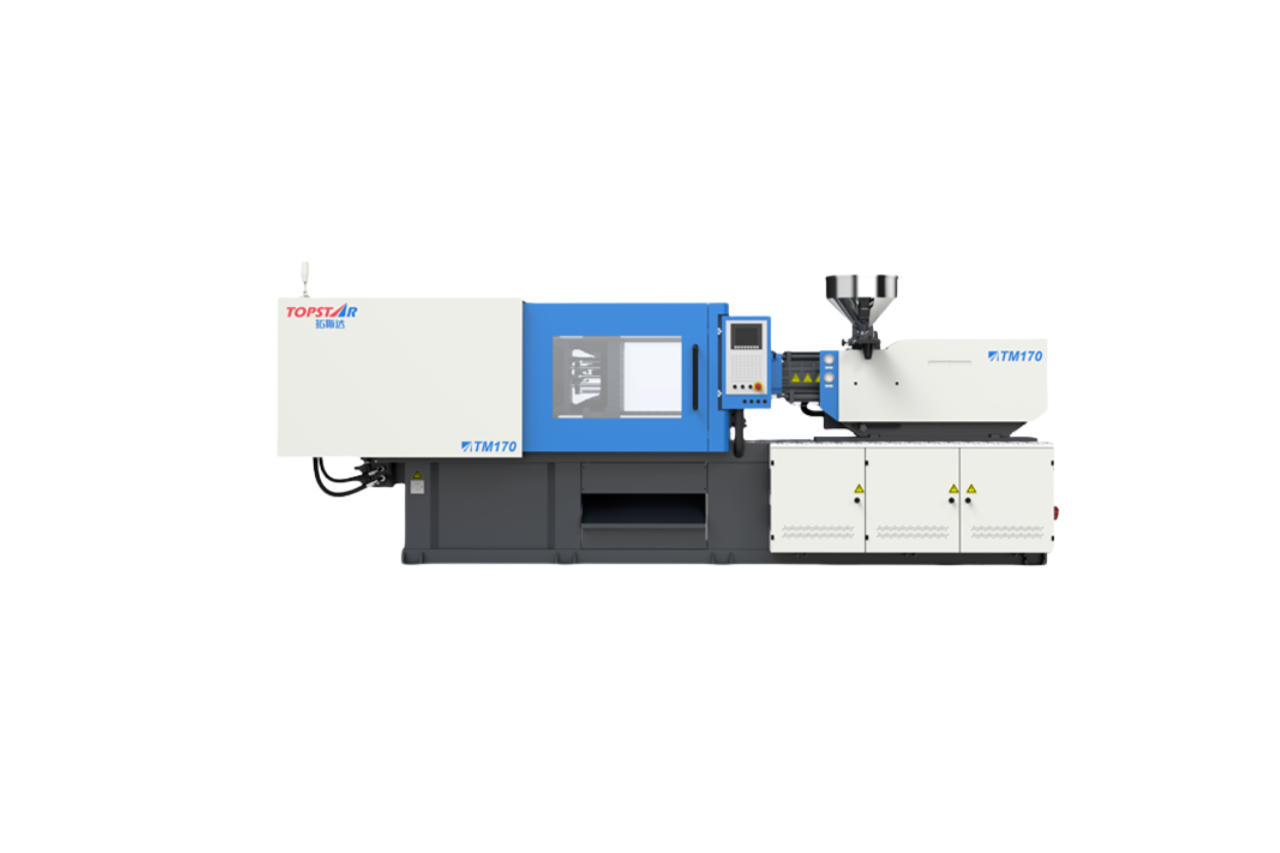

India is one of the fastest-growing economies in the world, and its strong market demand for plastic products has also attracted the attention and participation of many global plastic machinery companies. At the same time, for many Indian plastic product manufacturers, production still faces problems such as unstable regional voltage, high demand for energy-saving Injection… Continue reading Using Topstar’s plastic injection molding machines to solve production problems for Indian users

Using Topstar’s plastic injection molding machines to solve production problems for Indian users