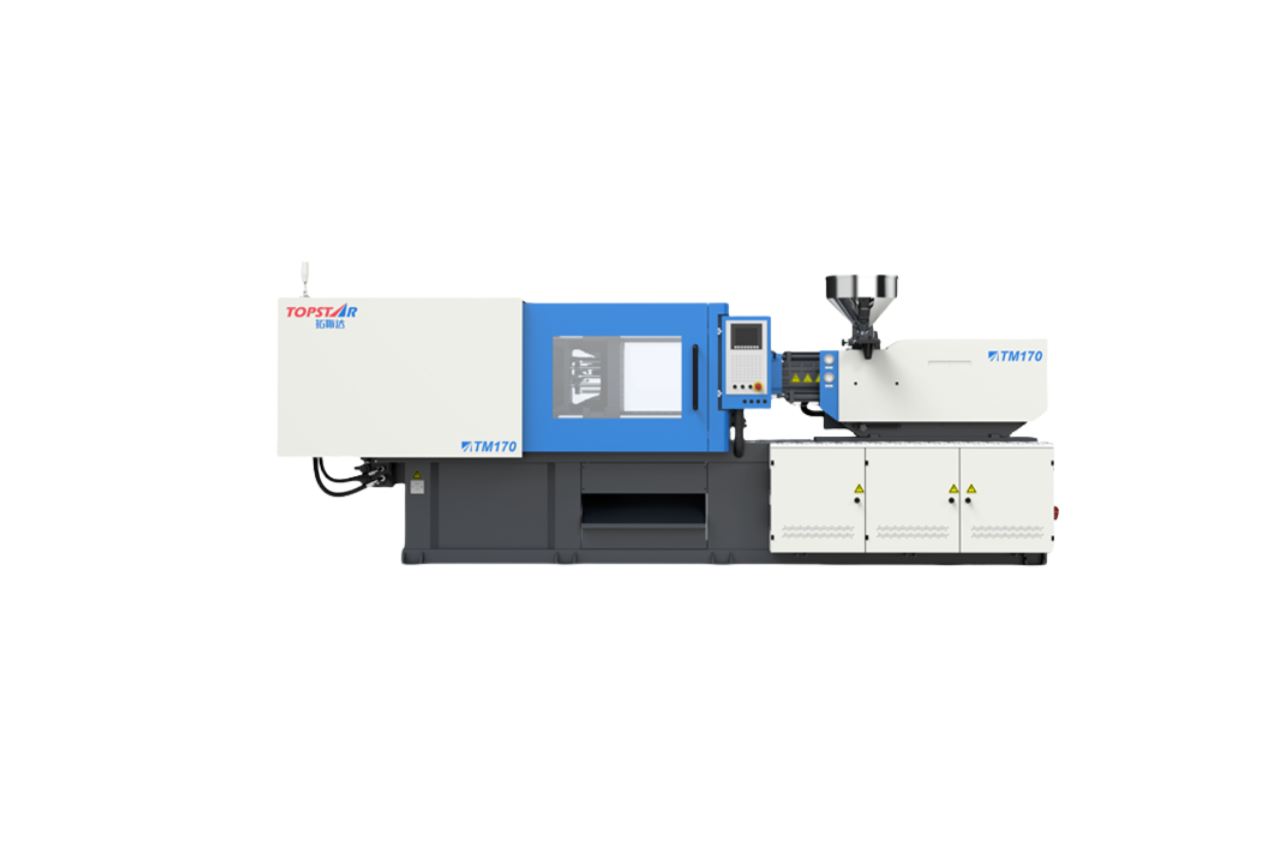

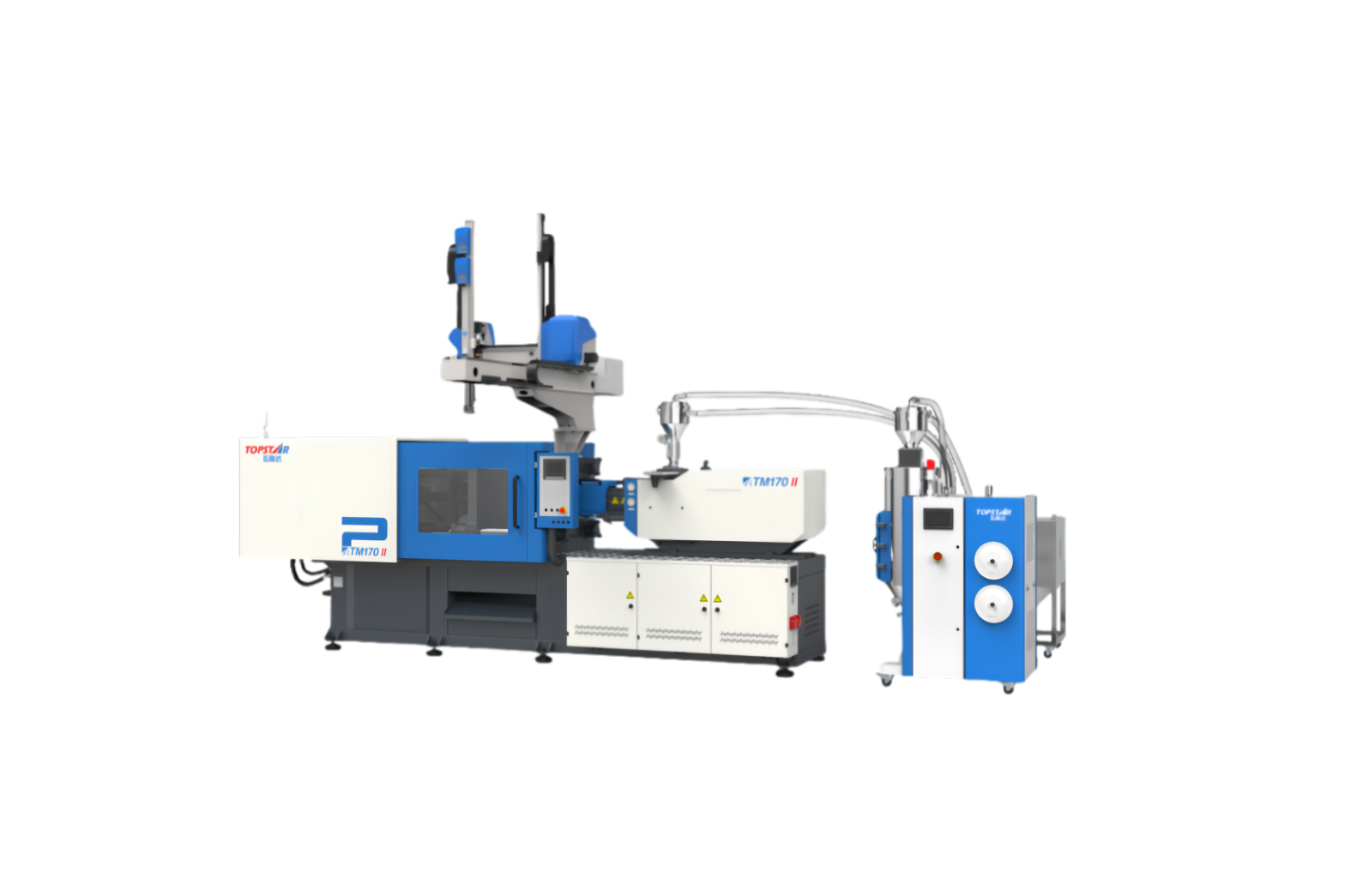

In the injection molding industry, the design of the screw in the injection molding machine plays a vital role. It has a certain impact on the quality and efficiency of the molding process. The current injection molding machine market is almost all electric injection molding machines for injection molding. Their precision, energy-saving, and control capabilities… Continue reading How is the screw design of a all electric injection molding machine different from that of other machines?

How is the screw design of a all electric injection molding machine different from that of other machines?