Provide integrated injection molding machine solutions for different customers

2024/11/01 By Topstar

With the rise of the auto parts, medical, and optical products industries, the corresponding manufacturing industry is facing intense competition, and the demand for injection molding machine efficiency, precision, and adaptability is higher than ever. In the face of different overseas countries, Topstar can know the challenges they face in injection molding and can provide customized integrated injection molding machine solutions to meet the specific needs of our different customers. It will combine core technology-driven control systems with industry expertise to ensure our customers achieve production goals while optimizing operational efficiency.

About integrated injection molding machine solutions

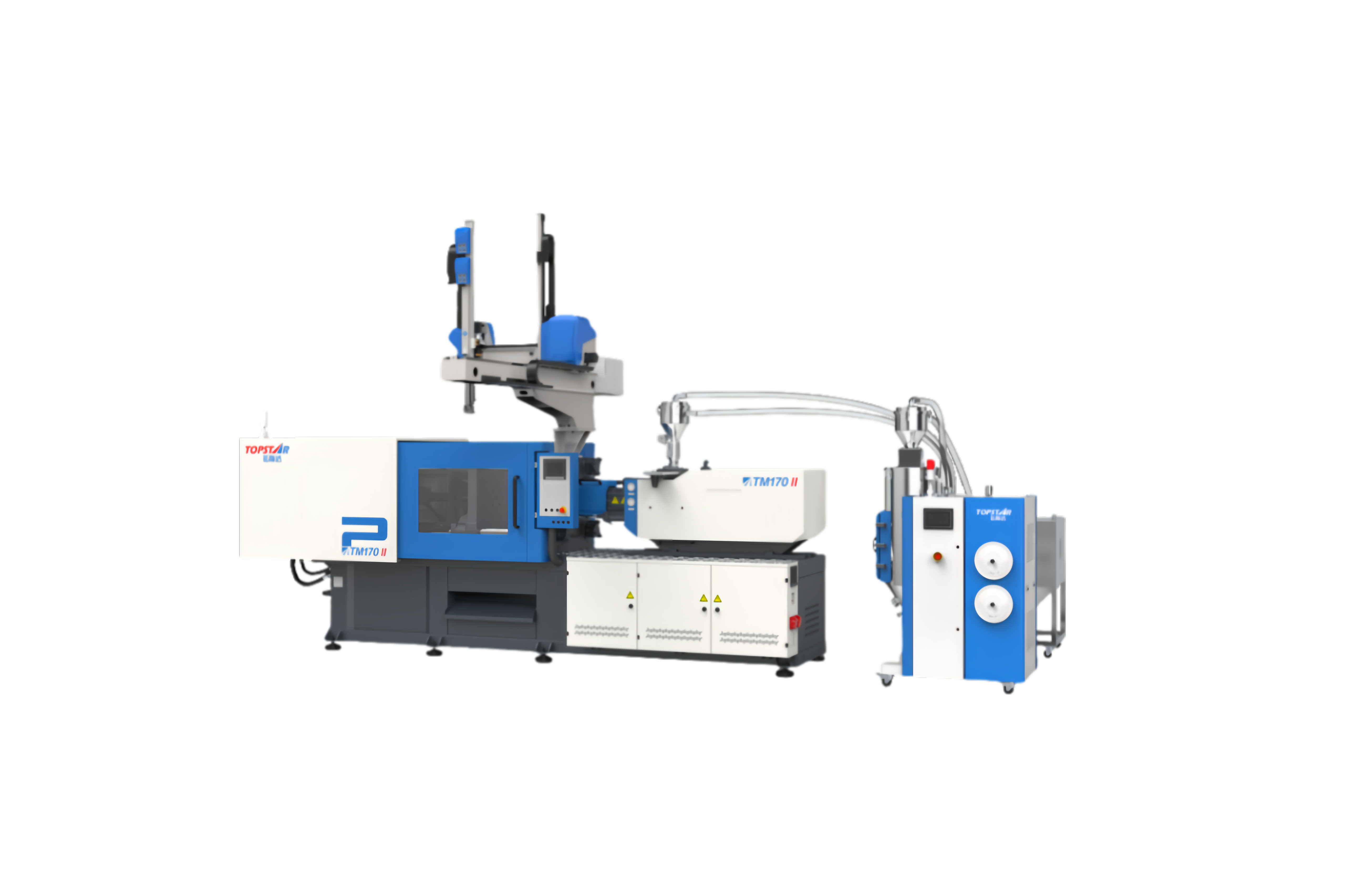

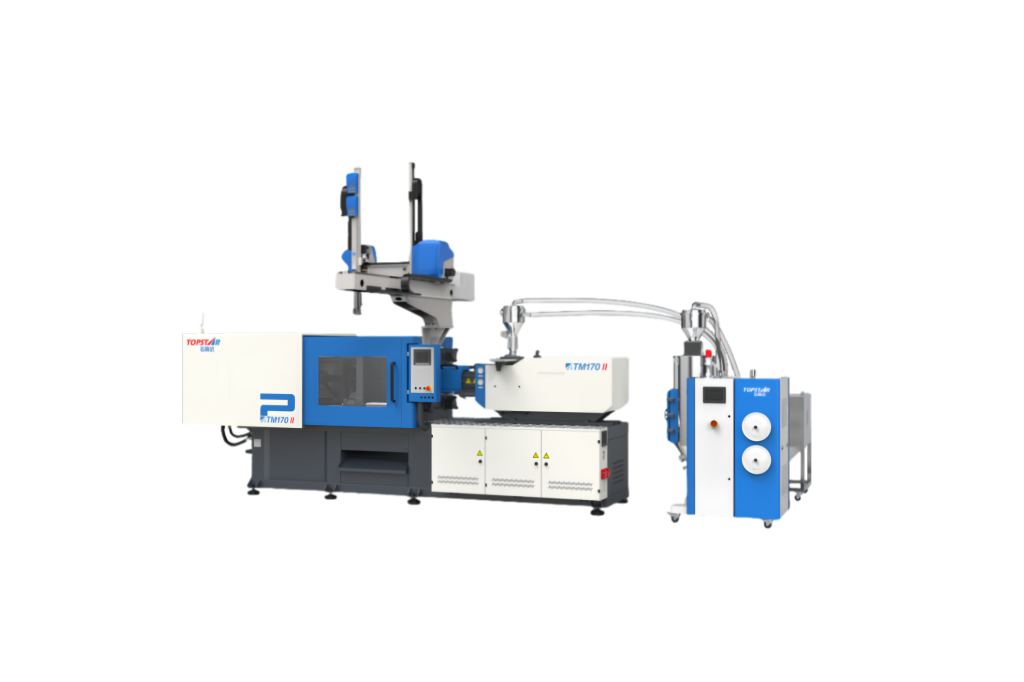

Integrated injection molding machine solutions refer to a seamless combination of machinery, processes, and support services that work together to improve production capabilities. Topstar will provide a range of injection molding machines based on your product needs and actual production conditions to meet the needs of various applications, from automotive parts to consumer products. This solution allows injection molding machines to integrate smoothly with existing production lines, minimizing downtime and maximizing production. Providing tailored solutions, including advanced control systems, automation technology, communication compatibility, etc., ensures that customers can efficiently produce high-quality products while reducing costs and resource consumption. Achieve a streamlined production process to increase productivity and maintain the highest quality standards.

Case: Meeting Egypt’s unique customer injection molding machine needs

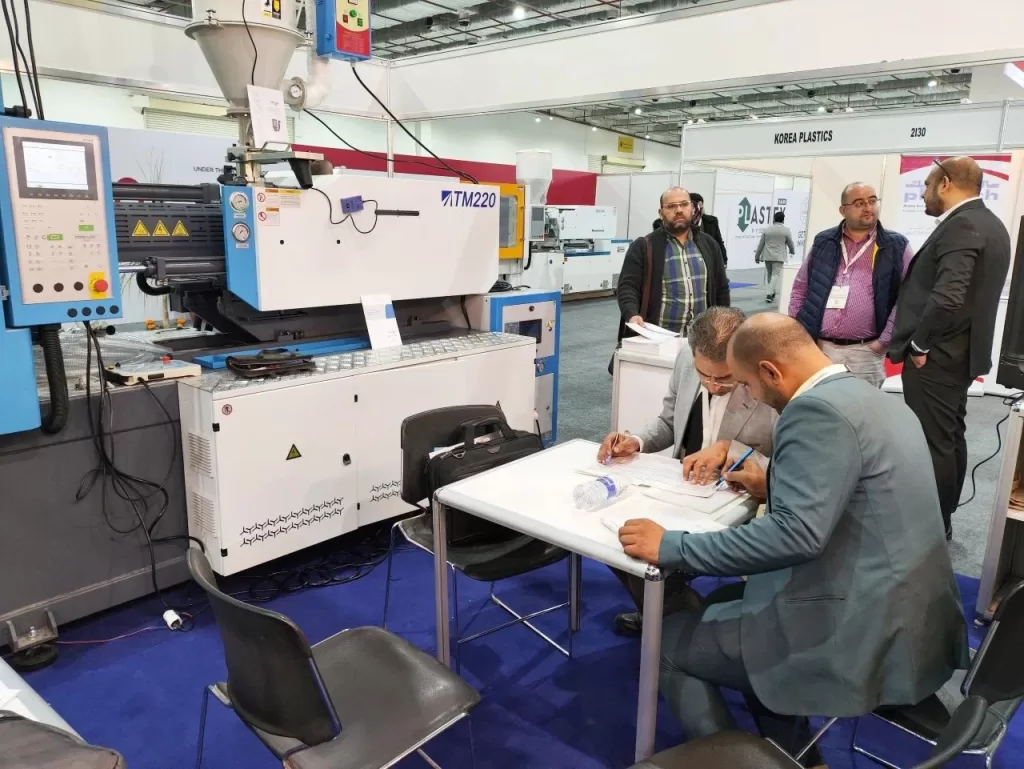

Topstar participated in the Egyptian Plastics and Rubber Exhibition PLASTEX in January this year. Together with local partners, we exhibited the TM220 injection molding process all-in-one machine, which is based on the injection molding needs of Egyptian customers for auto parts and product packaging.

In recent years, Egypt’s auto parts industry has experienced huge market demand. According to statistics, Egyptian auto manufacturers’ production capacity has reached 100,000 vehicles per year, while Egypt’s annual car sales are about 200,000. Local and international manufacturers mainly compose the auto parts market. In the Egyptian market environment, local customers have high participation and hope to serve the market by introducing high-end equipment.

Topstar focuses on customer demand, develops equipment that meets customers’ participation in emerging markets through three core technologies, and provides directional solutions. The TM series injection molding process all-in-one machine we exhibited is a control system driven by core technology, which realizes the signal connection between the primary and auxiliary equipment. This equipment’s integrated control, linkage, and compensation characteristics can help customers improve the yield of industry products during production.

Control system driven by core technology

In the TM series injection molding machine, the control system driven by core technology can achieve high-speed and high-precision motion control and complex logic control, and multiple technologies can ensure that the injection molding machine runs faster and more smoothly. The use of advanced algorithms can enhance process automation. This includes automatically adjusting molding parameters based on real-time feedback so that the parameter setting and working condition monitoring of peripheral equipment are integrated into the injection molding machine controller, ensuring that each cycle meets the precise specifications required for high-quality output. Therefore, this holistic approach ensures that every aspect of the operation meets the exact specifications for high-quality output, reducing differences and improving consistency. In addition, the system supports advanced communication protocols for seamless integration with other manufacturing systems.

Unique automatic mold opening position compensation function

The injection molding machine control system communicates with the injection molding robot through the bus, sending the deviation position to the injection molding robot, and the injection molding robot tracks the position. This difference can save 50-70% in energy, depending on the production environment and the type of parts manufactured. This active tracking and compensation mechanism enables the robot to “actively” correct any differences in the mold opening and closing cycle. This adaptability is critical to achieving faster cycle times, which is essential in mass-production environments. By minimizing the risk of misalignment, it can accurately grasp and handle the injection molded products, reducing the possibility of defects caused by improper handling. This can improve product quality and increase the overall efficiency of the production line. At the same time, this feature also supports complex manufacturing requirements, using multi-cavity molds or complex designs that require precise handling.

More environmentally friendly injection molding solutions

Choose global awareness of environmental issues is increasing, not just in Egypt. Manufacturers in different parts of the world are increasingly seeking sustainable practices to minimize their ecological footprint. Topstar also prioritizes sustainability in integrated injection molding machine solutions. The machines we design are energy-efficient and efficient, reducing power consumption and operating costs while maintaining high-performance levels. Our environmental protection is not limited to improving energy efficiency. We also focus on optimizing material use and reducing waste throughout production. We help customers align their operations with sustainable development goals by implementing recycling systems and promoting biodegradable materials.

Meet your different needs

Topstar is committed to providing integrated injection molding machine solutions to meet the unique needs of our different customers. By focusing on customization, advanced technology, and comprehensive support, we help customers achieve production goals efficiently and effectively. No matter what type of company you are, Topstar will support you in achieving operational excellence.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/11/01

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/11/01

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/11/01

- Topstar Special | National Science and Technology Workers Day 2024/11/01

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC