Injection molding equipment

Injection Molding Machine

To improve equipment performance and ensure production and operational efficiency, Topstar has developed an "integrated process machine," which combines the main machine, auxiliary equipment, and automated control, thereby increasing production efficiency. Our injection molding machine series has clamping forces ranging from 90 tons to 2800 tons, including servo-driven, hybrid, and all-electric injection molding machines. This results in more efficient and stable production.

Products

Injection Molding Machine

Products

Injection Molding Machine

- High Performance

- Reliability

- Durability

- Universally Applicable

What is an

"Injection molding process Integrated machine"?

The core competitive advantages of the “Integrated Injection Molding Process Machine”

The “Integrated Injection Molding Process Machine” achieves communication between the main machine, auxiliary equipment, and automation systems through a self-developed control system. The core is the integration of software systems, enabling a single control interface to manage multiple devices and optimize the entire injection molding process, including pre-processing of raw materials, plasticization, molding control, and part removal. Through system integration, the combination of main and auxiliary machines, and sensor technology, it achieves optimal control of injection molding factors such as temperature, speed, position, pressure, and time. This results in higher production efficiency and quality control, meeting customers’ comprehensive needs for production efficiency and management levels.

TEII Series Electric Injection Molding Machines

The TEII series of all-electric injection molding machines is divided into the TE II all-electric and h-TE II hybrid models, sharing a common platform. This series follows the concept of “integrated injection molding process,” allowing for real-time adjustment of multiple parameters to adapt to different materials and geometries. It achieves high-speed data transmission and coordinated control between various control units. The discrete intelligent drive control directly acts on the servo motor, minimizing communication delays during high-speed cycles and ensuring stable and precise molding in various applications.

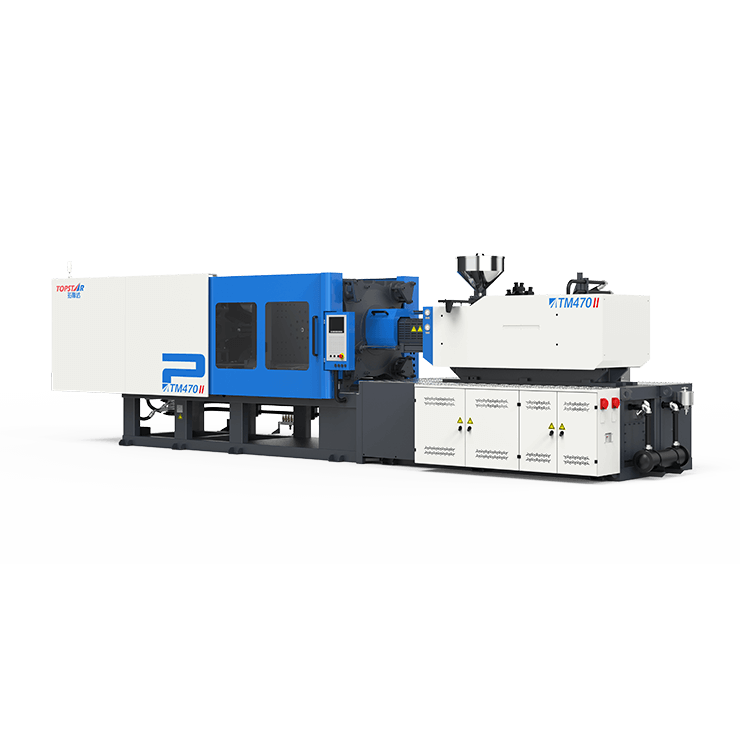

TMII Series Servo-Driven Injection Molding Machine

The TMⅡ series injection molding machines integrate the concept of “integrated injection molding process,” enabling linkage between multiple devices through a single control interface. They feature automatic mold opening position compensation and can work in conjunction with injection molding robots for precise handling. Real-time communication optimizes every step from material pretreatment and plasticization to molding and demolding, ensuring seamless coordination between all equipment. The upgraded hydraulic circuit utilizes a large-capacity oil system, enhancing the lubrication performance of the servo injection molding machine. As a result, it operates with lower noise, less leakage, and greater stability.

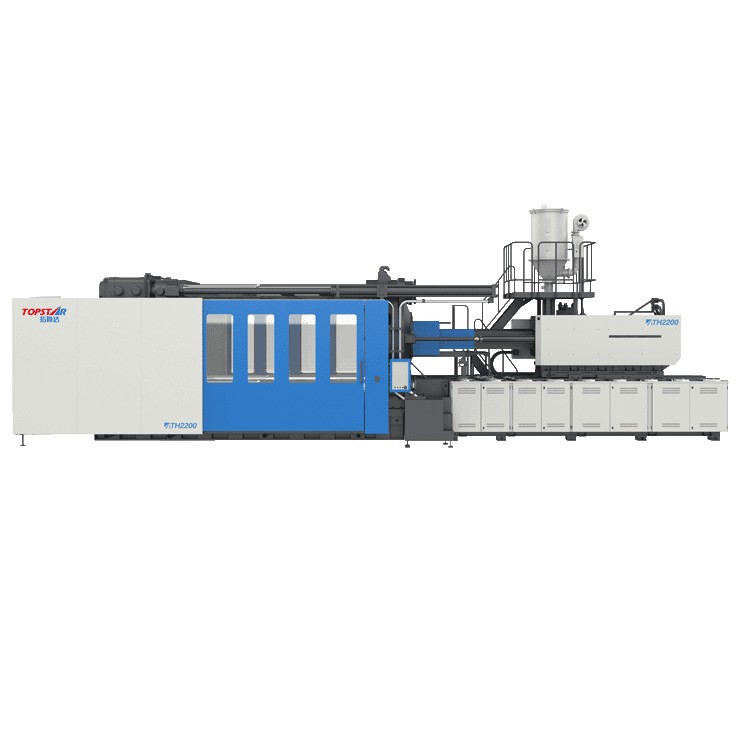

TH Series Direct Press Type Injection Molding Machine

The TH series of direct-pressure injection molding machines is divided into two series: small and medium-to-large. Both series utilize standardized clamping and injection platforms. These injection molding machines employ a double-platen direct-pressure central clamping structure, providing the maximum possible mold opening stroke. The small direct-pressure injection molding machines use a central direct-pressure clamping structure, significantly increasing mold clamping force and providing robust stability for each cycle. The multi-cylinder direct-pressure clamping design on the medium-to-large injection molding machines provides extremely high mold clamping force, enabling stable handling of large and complex molds. They are specifically designed for demanding applications such as automotive panels and thick-walled PMMA headlights.

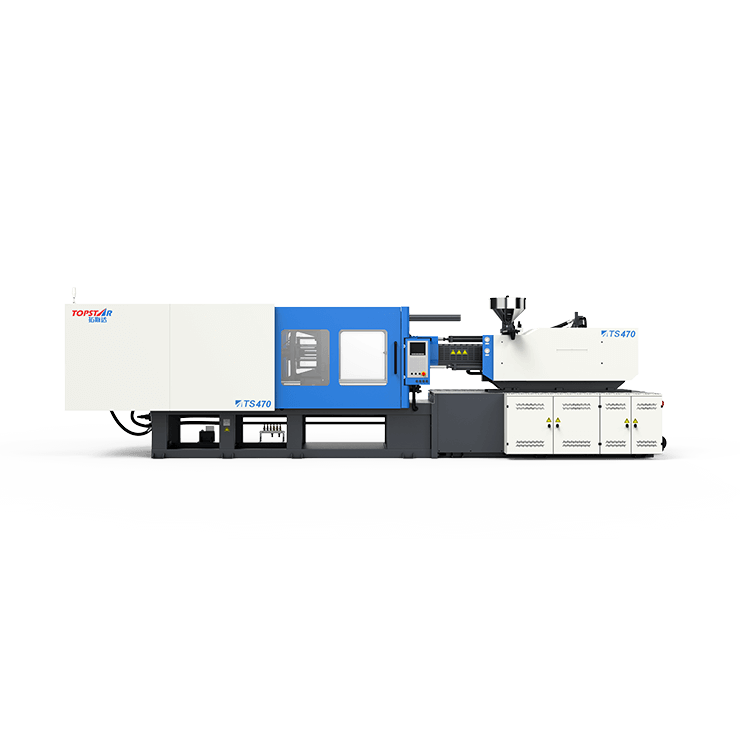

TS Series Toggle Hydraulic Injection Molding Machine

The TS series injection molding machines utilize an advanced hydraulic system design and are equipped with a professional controller, ensuring stable machine operation, high product yield, and fast response speed. Simultaneously, the use of inclined double injection cylinders and linear guides enables more precise and stable injection. Furthermore, ceramic heating elements and temperature control at the material inlet improve temperature accuracy and sensitivity, thereby increasing productivity. The reinforced platen in this series enhances its toughness, reducing platen deformation to 0.2 mm/meter. This rigidity ensures product precision, especially under high-speed and high-pressure operating conditions.

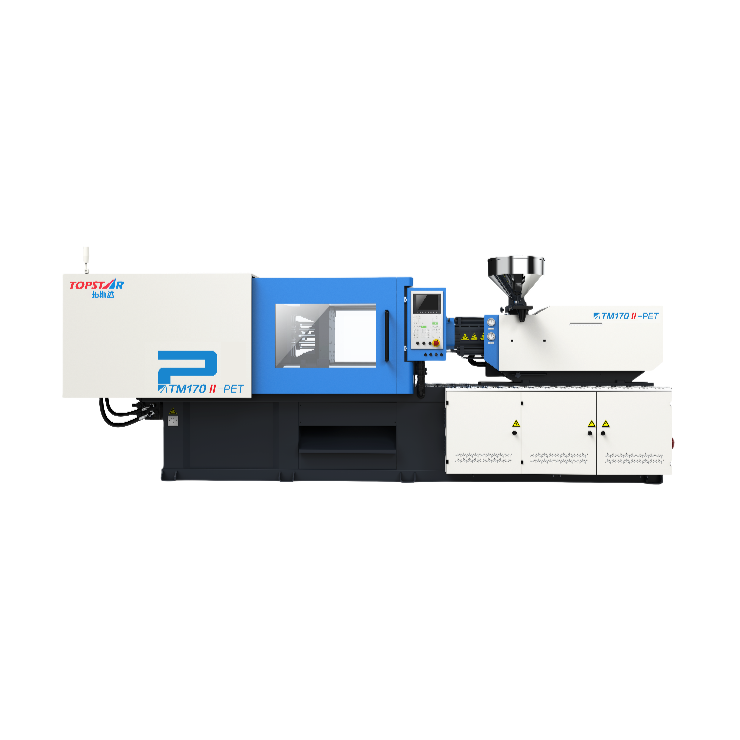

TMⅡ-PET Series Injection Molding Machine

The TMII-PET series injection molding machines are designed for high-precision, high-efficiency production of high-quality preforms. This series of preform injection molding machines excels in speed, professionalism, and efficiency, offering a high-rigidity, high-efficiency, energy-saving, and integrated injection molding solution. The entire machine frame features a targeted oil-resistant design, resulting in a more compact overall size and making it more suitable for clean workshop environments. It also utilizes a PET-specific screw assembly, ensuring excellent plasticization quality and high efficiency. This reduces plasticization temperature and acetaldehyde (AA) levels, effectively improving product shrinkage, increasing transparency, reducing energy consumption, and boosting production efficiency.

Training for Installation and Operation Correctly

Topstar Service

We have a comprehensive after-sales training system. To address potential issues and ensure optimal operation, we provide you with the necessary training resources for installing and operating the packaging machine.

- Instructions for Use – Installation Steps and Operating Precautions

- Video demonstration of installation and debugging

- On-site training – additional service fee required

Technical Support

Whether your business is located in Europe, North America, or the Middle East, we provide global services, and our experts are on call to provide technical support services through video calls or on-site assistance. Services include:

- First installation and debugging of equipment

- Daily debugging and maintenance

- Emergency fault assistance

- Equipment optimization services

The Machinery Industry Professionals

- Customized Requirements

- Solutions

- Professional Packaging

- Delivery & Installation

- 24H Technical Support

The Topstar team delivered the Water & Electric Engineering project efficiently and perfectly in a complex environment with an urgent delivery schedule.

LUXSHAREICE

From EEA series to TE series, we see the continuous pioneering and innovative spirit of Topstar in the field of injection molding machines.

Dme Udaykumar

The robotic arms were installed and ran smoothly, which greatly improved our production efficiency!

Thai A-Tech

Listen To The True Voice Of Customers

We sincerely appreciate that more than 15,000 customers have witnessed the TOPSTAR growth and long-term supports.