About what is a desktop injection molding machine? Topstar has a professional explanation

2021/12/24 By Topstar

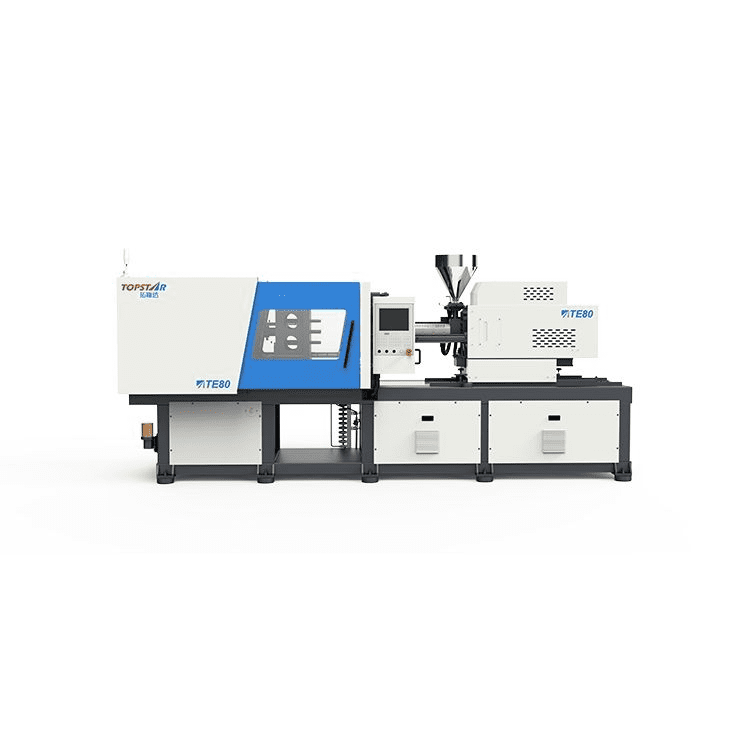

What is the benchtop injection molding machine?

Desktop injection molding machine is a mechanical process standard in various production cycles for permanently molding multiple materials, including plastics. Find out on this page what injection molding is, in which fields it is expected, the plastic components and objects manufactured, the mold production, and the precision molding of plastic materials.

What is Molding?

The term “molding” includes the most disparate industrial production processes, the lowest common denominator of which is molds, which are permanent forms necessary to model the product or components to be produced.

More specifically, it is a mechanical process for plastic deformation, hot or cold, which causes the material to fill the cavity between two metal matrices, the mold and the counter-mold.

WHAT IS PRECISION MOLDING?

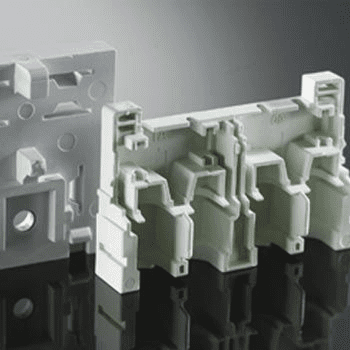

One type of molding is that of a desktop injection machine. The current technological development requires production techniques with an ever-higher degree of precision, through which it is possible to manufacture finished products, components, and micro-components with complex geometry for cars, computers, and other applications.

These components have dimensions of just a few millimeters and have weights of 0.2 g, requiring injection volumes of less than one granule and geometries of less than one millimeter (micro-molding).

How do these benchtop injection molding machine function?

Plastic injection molding consists of five main phases, which we can summarize as follows:

- The pellets are in preparation for injection.

- The material is compulsory through the nozzle of the injection unit and then ends up in the sprue and finally into the cavity of the mold evenly.

- Once the plastic material is excellent and hardened, the mold is open, and the molded part is homeless.

- Finally, the set piece is completed by cutting the sprue and sprue.

A few tricks for a perfect molding process

Although the molding, even with precision, is performed by special machines, there are some factors to take into consideration to obtain a more than-perfect result:

- First, the molten plastic material distributes uniformly in the mold.

- Moreover, the resinous material must be chosen according to the product to be manufactured, considering its chemical-physical and aesthetic characteristics.

- Last – but not least -, the mold must be designed and produced with the utmost precision to prevent errors or smudges that waste time and costs.

Types of benchtop injection molding machines

- Motorized,

- hydraulic,

- servo-driven,

- hybrid,

- CNC machines:

Many kinds of devices and presses can be suitable for molding.

In general, however, we can say that a molding machine is made up of two main parts: a desktop injection machine unit that sends the molten material inside the mold and a closing unit that, on the other hand, manages the mold.

The materials common in the desktop injection machine

The Thermopolymers are the plastics which is common mainly in injection molding because they possess various competitive advantages:

- They are easily workable

- They have excellent dimensional stability.

- withstand dynamic loads and aging

- They maintain good mechanical properties even above 100 ° C

The most common techno polymers in desktop injection machine, including precision ones, are

- PMMA,

- PEI,

- Also, PPS,

- Moreover, PC,

- Furthermore, PBT,

- PPO,

- In addition, POM,

- Also, ABS,

- PC / ABS,

- PPA,

- PA6-PA66,

- PP,

Structure or resistance to temperature can be classified into:

- amorphous or semi-crystalline, i.e., transparent or opaque

- standard – common at temperatures below 100 ° C – or technopolymers – usable at temperatures between 100 ° C and 150 ° C

WHEN IS THE PLASTIC MOLDING PROCESS REQUIRED?

Precision, production speed, and relatively low costs are undoubtedly the reasons why, to date, plastic molding is increasingly applied in the most diverse sectors to produce:

- Automotive components and accessories

- Consumer electronics

- Medical and orthodontic supplies

- everyday products

- components for gates and industrial automation

Rapid development in the desktop injection machine

The relatively rapid development and the ever-higher precision of the technique have meant that many companies resort to desktop injection molding machines of plastic to produce components – especially electronic ones – with tiny dimensions and complex geometry, difficult to reproduce with other techniques.

desktop injection machine Sectors of application

The versatility of plastic polymers and their physical, chemical, and mechanical characteristics allow them to be expected in numerous sectors, so much so that they can also be common to manufacture objects or components we use daily.

The sectors that, more than others, use molding or precision molding are:

- Building and Housing

- Also, electrical, electromechanical, and electronic

- Moreover, household appliance heating

- Furthermore, food and personal care

- In addition, industrial automation

- medical

What are the benefits of a desktop injection machine?

Plastic injection molding is a highly versatile technique that meets almost any need of companies that manufacture plastic products and components in large volumes and a few dozen pieces.

Here, in brief, are the advantages of the desktop injection machine of plastics:

- High productivity and speed – This technique allows obtaining large quantities of plastic parts in a short time, guaranteeing dimensional repeatability

- possibility of getting shapes in disarray and complex geometries, impossible to obtain otherwise

- A very high degree of precision, to which we also resort to the technique of microinjection molding

- reduction of production costs through the automation of the entire injection molding process

desktop injection machine support system

In the injection molding support system, four subsystems perform their functions.

• Body: Link the systems of the machine together

• Power system: is the place to provide power for the motor to operate. The design of the machine’s electrical system focuses on operator safety. The electrical system consists of an electrical cabinet and a wiring system.

Desktop injection machine Hydraulic system:

Including pump, valve, pipe system, and motor. It is the place to generate resources such as creating force to open and close the mold, maintaining clamping force, making the screw rotate, and developing staff. For the pushpin and the slide of the surface core.

• Cooling system: Provide water or Ethylene glycol solution… to cool the mold and harden the plastic into shape before pushing it out of the mold.

Conclusion

We offer our customers various services ranging from mold design to molding of plastic components. Depending on some characteristics such as, for example, the type of product made, the material of the mold, and the compulsory geometry.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2021/12/24

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2021/12/24

- Star Case | Topstar helps Santong upgrade its intelligent plant 2021/12/24

- Topstar Special | National Science and Technology Workers Day 2021/12/24

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC