What Is an Injection Manipulator and How Does It Help You?

2023/05/22 By Topstar

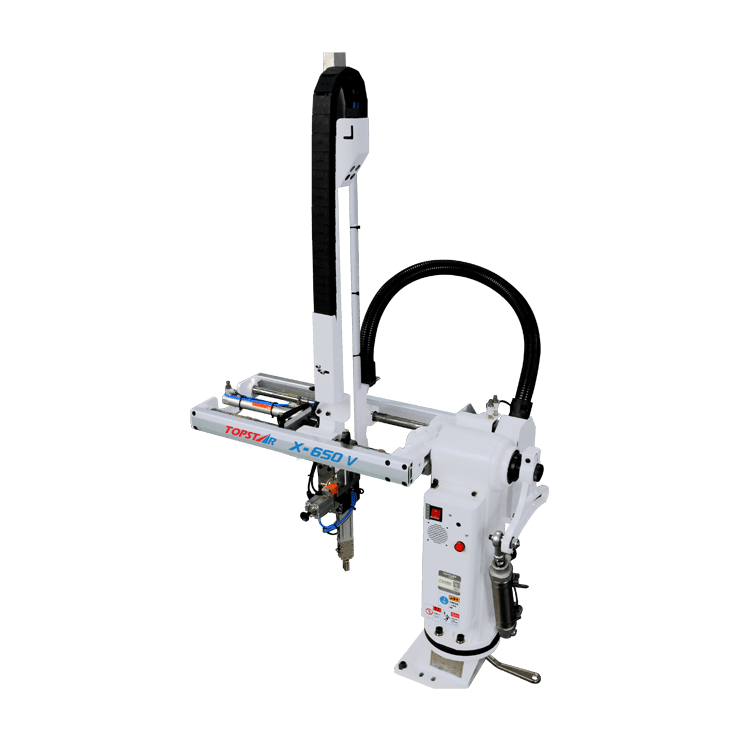

An injection manipulator is a great tool to have on hand if you do any manufacturing. These devices help you control the flow of liquids and gases, increasing productivity and quality. So what is an injection molding robot? An injection manipulator is a tool that helps control the flow of liquids and gases. When using an injection robot, it is essential to remember that it cannot compensate for poor design or materials in your product. Investing in quality manufacturing equipment like this is a must to manufacture flawless, quality plastic parts!

This is a tool that helps control the flow of liquids and gases!

An injection manipulator is a tool that helps to control the flow of liquids and gases. It is suitable for injection molding, where molten plastic is injected into molds to create parts. The injection manipulator controls the rate of injecting said plastic into your mold, ensuring you don’t overfill or underfill your molds with the material.

The equipment also facilitates industrial processes that mix several materials into one product. For example, if you make paint at home using multiple ingredients, the injection robot will ensure that each color is evenly distributed. Work overall coats of paint before the paint dries on its own so you don’t leave any streaks when you’re done!

An injection manipulator is a helpful device for handling liquids or gases during industrial processes!

An injection manipulator is a device that helps you control liquid or gas flow during industrial processes. Injection manipulators come in many different types, suitable for other purposes. For example, if you’re manufacturing electronics, an injection robot can help you perform tasks like soldering wires without wetting them. It would typically be difficult because liquids tend not to stay in one place (they move).

Injection molding robots also make it easier for workers on production lines that involve multiple steps to increase productivity and quality. Instead of having each worker manually handle each product in their section along their line, the injection robot allows them to load all the material into one place at a time. This way, they are not exposed to harmful chemicals that could endanger their health while working.

How Does an Injection Manipulator Work?

Injection manipulators control the flow of liquids and gases during the injection molding. They are also suitable for other manufacturing processes, but we will focus on their use in injection molding. In this case, an injection manipulator consists of a flow controller and an electronic valve (or “gate”). The flow controller allows you to control the temperature of the liquid or gas injected into your mold–and some models come with both functions built in! Other models only have one or the other, so if you want to adjust both parameters simultaneously, look for one with both capabilities built in.

The electronic gate controls how much material enters each cavity at any given time throughout each cycle (called “injection pressure”). You can adjust these settings depending on the type of material you are using; if something doesn’t come out immediately after being injected into the cavity, try changing these values until everything returns to normal.

An injection manipulator is a great tool to have on hand if you do any manufacturing!

An injection manipulator is a great tool to have on hand if you do any manufacturing. It helps control the flow of liquids and gases during industrial processes, making it easier to handle liquids or gases during industrial processes. You can use an injection manipulator to move liquids from one place to another without spillage or contamination.

The injection manipulator looks like a syringe but without a needle at the end. Instead, the two tubes are connected by valves that allow fluid to flow between them as needed. One box contains pressurized gas, while the other contains liquid under pressure (usually water). When the two fluids meet inside your product container, they mix seamlessly without turbulence caused by air bubbles entering your mixture before the injection point. This results in better consistency when mixing batches, as there won’t be any streaks remaining on the top surface area.

Injection Manipulators Improve Productivity and Quality of Plastic Parts

An injection manipulator is a device to improve the quality and productivity of plastic products. They do this by dispensing the correct material and ensuring that each piece is produced precisely as intended. This helps manufacturers save money by reducing waste and increasing their profit margins by providing a high-quality product at a competitive price.

In addition to improving these two areas, injection manipulators offer other benefits, such as increased worker safety and reduced production time, as they can perform tasks faster than a human could achieve alone. These factors make them an attractive option for many industries, from automakers wanting to fit better parts on their cars to construction companies looking for more robust building materials.

To sum up

An injection manipulator is a handy tool to help you make injection molding easier and more accurate. The above descriptions let you know more intuitively about the injection manipulator, how it works, etc. You can contact us if you have other questions about the injection manipulator!

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2023/05/22

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2023/05/22

- Star Case | Topstar helps Santong upgrade its intelligent plant 2023/05/22

- Topstar Special | National Science and Technology Workers Day 2023/05/22

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC