Advanced Control Systems for Swing Arm Robot in Injection Molding

2023/11/06 By Topstar

Swing arm robot play a key role in automating the injection molding process, improving precision and efficiency. However, what enables these robots to operate seamlessly is the advanced control system that manages them. These systems have evolved significantly, providing a rich set of capabilities that increase accuracy, efficiency, and productivity. We will delve into the complex world of advanced control systems for swing arm robots, examining their professional impact and technical capabilities in the injection molding industry. From innovative software solutions to real-time monitoring, various cutting-edge technologies are a vital component.

Improve accuracy and path planning

One of the most significant advances in swing arm robot control systems is the integration of sophisticated path-planning algorithms. These algorithms help optimize the robot’s movements, ensuring precise and efficient removal and placement of molded parts. These algorithms harness the power of 3D modeling and simulation to enable robots to visualize the workspace and determine the most efficient path to minimize cycle time. Factors such as part geometry, mold design, and end-effector functionality are carefully considered, improving accuracy and efficiency. Furthermore, these advanced path planning algorithms not only optimize the robot’s trajectory but also consider other parameters such as payload, reachability, and obstacles within the workspace.

Real-time monitoring and adaptive control

Modern swing arm robot control systems are equipped with real-time monitoring functions, ushering in the era of adaptive control. These systems have the flexibility to detect deviations or anomalies in the injection molding process and perform on-the-fly adjustments. For example, suppose a part fails to eject smoothly from the mold or encounters an unexpected obstacle. In that case, the robot can dynamically re-evaluate its approach and make necessary corrections to ensure uninterrupted operation. This adaptability not only reduces the likelihood of errors but also helps improve overall efficiency.

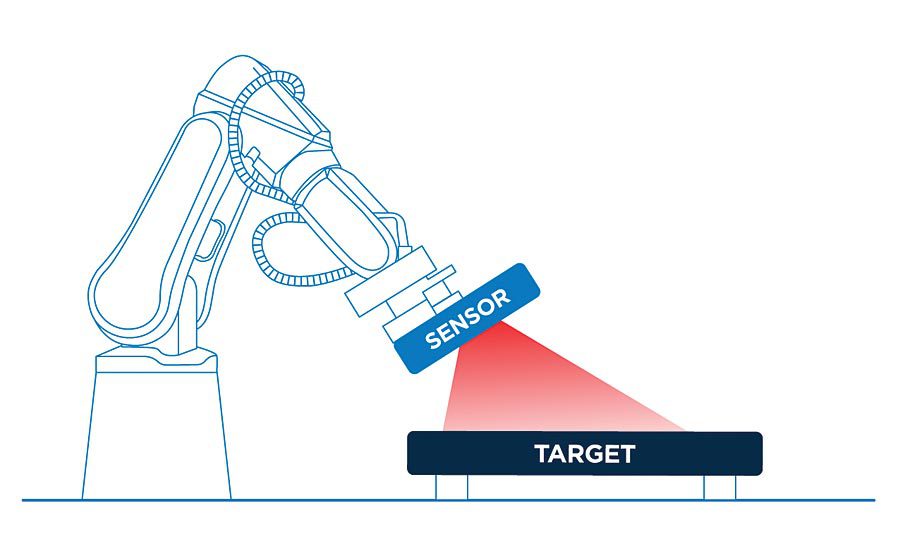

Swing arm robot intelligent vision system integration

Another significant advancement in swing arm robot control systems is the seamless integration of intelligent vision systems. These systems utilize cameras and sensors to provide visual feedback to the robot. This allows the robot to not only identify parts but also pinpoint the exact location of the part and even check for quality issues. Vision systems become especially invaluable when elements exhibit complex geometries or different orientations. The ability of robots to adapt to different part configurations without human intervention highlights the complexity of contemporary control systems. More than just part identification, these systems can perform quality control checks, identify defects, and ensure that each piece meets predetermined quality standards. This level of sophistication helps significantly reduce defects and waste in the manufacturing process.

Harmonious integration of swing arm robot and injection molding machine

The advanced swing arm robot control system is carefully designed to ensure harmonious integration with the injection molding machine. This symbiotic relationship ensures that the robot and the molding process operate in harmony, further increasing efficiency. Critical parameters such as cycle times, temperature profiles, and mold changes can be synchronized to optimize production. The result is a well-designed manufacturing system that minimizes downtime and maximizes productivity. This level of integration extends to data exchange between the robot and the injection molding machine. Data such as mold changes, production quotas, and part specifications are communicated seamlessly between the two systems, enabling streamlined and synchronized manufacturing processes.

Secure and comprehensive data logging

Advanced control systems prioritize safety and data logging. Implement user access controls to restrict unauthorized access to bot functionality and settings. In addition, these systems feature comprehensive data-logging capabilities that record essential information related to robot operations, such as cycle times, error logs, and performance metrics. Large amounts of captured data can be scrutinized to identify trends, optimize processes, and resolve issues, ultimately improving overall efficiency.

Safety is the most critical issue in modern manufacturing environments, and control systems have been developed to address these issues. Access control features ensure that only authorized personnel can interact with the robot’s control system, reducing the risk of unauthorized or malicious changes to the robot’s program. Additionally, these data logs can be used for predictive maintenance. By analyzing the data, operators can identify trends and patterns indicating potential problems or wear and tear on robot components. This proactive approach to care minimizes unplanned downtime and ensures the robot operates at peak efficiency.

In the end

These systems usher in an era of precision, adaptive control, intelligent vision, seamless integration with injection molding machines, and user-friendliness. At the same time, they have also strengthened security measures and established strong data logging practices to ensure operational efficiency and data-driven decision-making. These systems are essential for optimizing production processes, reducing errors, and increasing efficiency. If you want more related blog articles about the injection molding field, please visit our official website [https://www.topstarmachine.com/]!

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2023/11/06

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2023/11/06

- Star Case | Topstar helps Santong upgrade its intelligent plant 2023/11/06

- Topstar Special | National Science and Technology Workers Day 2023/11/06

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC