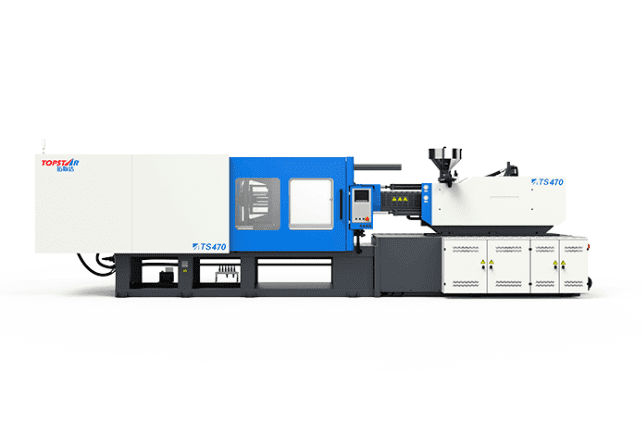

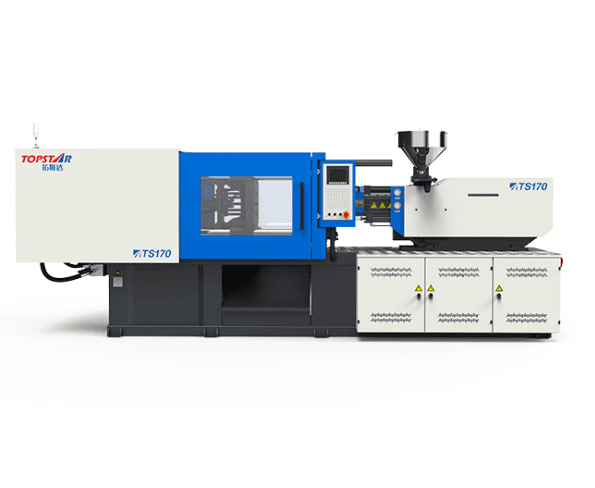

Exploring the Features of Toggle Hydraulic Injection Molding Machines

2024/02/23 By Topstar

Revolutionizing Plastic Manufacturing with Precision and Efficiency

In the ever-evolving landscape of plastic manufacturing, the Toggle Hydraulic Injection Molding Machine emerges as a technological marvel, promising to redefine industry standards. Our article today explores the characteristics that make toggle hydraulic injection molding machines a game changer. From its precision-forming capabilities to energy efficiency and environmental sustainability, we have embarked on a journey to unravel the complexity of this innovation.

Understanding the Essence of Toggle Hydraulic Injection Molding

The Fusion of Precision and Power

The Toggle Hydraulic Injection Molding Machine seamlessly integrates precision engineering and hydraulic power. This section overviews how the synergy between toggle mechanisms and hydraulic systems sets the stage for enhanced molding capabilities.

Breaking Away from Tradition: Advantages Over Conventional Hydraulic Molding

Delving into the limitations of traditional hydraulic molding, we explore how the Toggle Hydraulic Injection Molding Machine addresses these challenges, offering superior precision, speed, and energy efficiency.

Precision Redefined: High-Speed Toggle Mechanisms

Swift and Efficient Mold Opening and Closing

Its high-speed toggle mechanisms are at the heart of the Toggle Hydraulic Injection Molding Machine. This section dissects how these mechanisms facilitate rapid mold opening and closing, reducing cycle times and heightening overall efficiency.

Consistency in Every Mold: The Technology Behind Molding Precision

Precision is a hallmark of the Toggle Hydraulic Injection Molding Machine. Here, we analyze the technology that enables consistent control over the molding process, resulting in high-quality and uniform finished products.

Toggle Hydraulic Injection Molding Machines-Energy Efficiency and Sustainability

Optimized Hydraulic Systems

Toggle Hydraulic Machines optimize hydraulic systems for maximum energy efficiency. This segment explores the advancements in hydraulic technology that minimize energy consumption while maintaining peak performance, contributing to a more sustainable manufacturing process.

A Greener Approach: Reducing Environmental Impact

A crucial aspect of Toggle Hydraulic Injection Molding is its reduced environmental impact. We discuss how the technology aligns with eco-friendly practices, addressing concerns about energy consumption and waste generation in plastic manufacturing.

Flexibility in Action: Customization and Versatility

Adaptable Mold Configurations

Toggle Hydraulic Machines offer versatility in mold configurations. This section delves into the technology’s flexibility, allowing manufacturers to adapt swiftly to various production requirements.

Multi-Material Molding Capabilities

Exploring the applications and benefits of multi-material molding, we showcase how Toggle Hydraulic Machines accommodate diverse material requirements, opening up new possibilities for product designers and manufacturers.

Mastering Control: Advanced Control Systems

Real-time Monitoring and Adjustments

Integrating advanced control systems is a defining feature of Toggle Hydraulic Injection Molding Machines. We dissect the real-time monitoring and adjustment capabilities, showcasing how they enhance process stability and efficiency.

Predictive Maintenance for Seamless Operation

Toggle Hydraulic Machines often incorporate predictive maintenance features. This segment examines how these features minimize downtime, ensuring continuous operation and optimal machine performance.

Real-world Impact: Case Studies and Industry Applications

Driving Efficiency in the Automotive Industry

Examining how Toggle Hydraulic Injection Molding has revolutionized the automotive industry, we present real-world examples of increased efficiency, reduced waste, and improved product quality.

Beyond Automobiles: Success Stories in Consumer Goods and More

Highlighting success stories in producing consumer goods and diverse industries, we explore how Toggle Hydraulic Machines contribute to rapid, cost-effective manufacturing across various applications.

Overcoming Challenges and Embracing the Future

Navigating Initial Challenges

The adoption of Toggle Hydraulic Injection Molding faced initial challenges. We explore the hurdles manufacturers encountered and the strategies to overcome resistance, paving the way for widespread acceptance.

The Road Ahead: Future Technological Advancements

As technology continues to evolve, so do Toggle Hydraulic Injection Molding Machines. We discuss potential advancements on the horizon, from enhanced connectivity to artificial intelligence integration and their implications for the future of plastic manufacturing.

Toggle Hydraulic Injection Molding Machines-Unlimited innovation and potential

In conclusion, the Toggle Hydraulic Injection Molding Machine emerges as a transformative force in plastic manufacturing. This exploration of its features underscores its potential to reshape the landscape of modern manufacturing. As businesses seek increased productivity and reduced environmental impact, Toggle Hydraulic Injection Molding is a beacon of innovation, revolutionizing how we approach plastic manufacturing.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/02/23

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/02/23

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/02/23

- Topstar Special | National Science and Technology Workers Day 2024/02/23

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC