How to Ensure Scale-Free Operation in Hard Water Areas with Water-Type Mould Temperature Controllers?

2025/06/27 By Topstar

Using a mould temperature controller in areas with poor water quality can cause scaling on heaters and internal channels, significantly reducing heat transfer efficiency and resulting in uneven mould temperatures, extended cycle times, and costly downtime. Therefore, achieving scale-free operation in these areas is not only an added advantage but also a prerequisite for continuous, high-precision manufacturing. To address such issues and ensure scale-free operation in areas with hard water, we offer the Pure Water series of water-type mould temperature controllers, as well as methods such as utilising Teflon floats, upgrading copper heaters, and enhancing circulation efficiency to ensure scale-free operation.

Water-Type Mould Temperature Controllers using pure water closed loop circulation

To prevent scaling, the Pure Water series of water-type mould temperature controllers utilises a fully closed circulation system, which is filled with pure deionised water during the circulation process. First, technicians inject deionized water into a sealed container to eliminate mineral ions. Then, the system circulates this clean medium through the mould, heat exchanger, and finally back to the integrated water tank without exposing the internal channels to untreated tap water. By isolating the circulation from the external water source, we can protect the mould from metal ion corrosion, eliminate scaling, and maintain clean flow channels. At the same time, during the installation, we will insist that all installations follow this protocol to ensure that the moulds and controllers remain rust-free and scale-free, thereby eliminating temperature drift and pressure loss during long-term production.

Add Teflon floats to adapt to poor water quality.

In the mould temperature controller, we have added a liquid-level detection function. The use of Teflon floats can prevent oil, water, iron filings and liquids containing sediment from adhering to the floats by using its non-stick properties, thereby ensuring accurate liquid level sensing without causing mechanical wear. In addition, the chemical inertness of Teflon enables it to operate in chemically corrosive or contaminated water without any degradation or reaction with additives. Customers in areas with poor water quality, such as the UK, will opt for mould temperature controllers equipped with Teflon floats to ensure that the floats remain reliable even in challenging water supply conditions, thereby preventing pumps from running dry or overflowing. This simple and effective solution significantly reduces maintenance interventions and extends maintenance intervals.

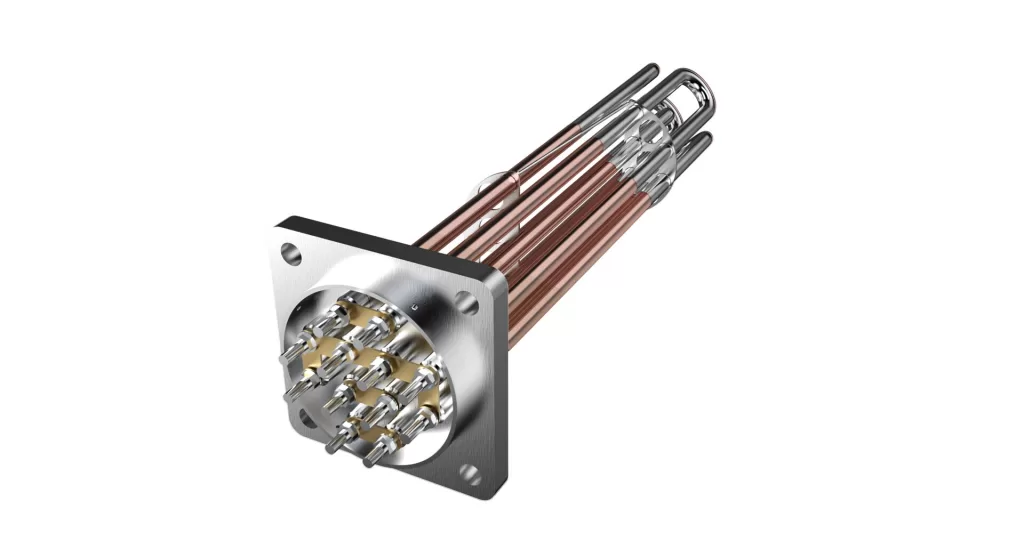

Upgrade the copper heater of the water-type mould temperature controllers to improve circulation efficiency.

In the water-type mould temperature controller, we have also upgraded the copper heating elements with a special anti-fouling surface treatment. Copper’s excellent ductility and high thermal conductivity ensure that heat is transferred quickly and evenly to the circulating medium. As a result, the system can reach the temperature setpoint faster, reducing preheating time by 15% and improving cycle consistency. Impurities in hard water are less likely to adhere to treated copper than to stainless steel, thereby minimising scale formation. In production R&D experiments, this copper heater has been proven to extend service life by 40% in a 1,000-hour accelerated ageing test and maintain a 10% higher heating efficiency, demonstrating its advantages in demanding moulding processes where temperature accuracy is critical.

Integrated water tank reduces water quality requirements.

A key design feature of the Topstar water-type mould temperature controller is the built-in water tank that holds precisely metered pure water. In addition to simplifying installation without the need for external water supply pipes, the integrated water tank stabilises the circulation pressure and water volume, ensuring that the coolant continues to flow through the mould consistently. Therefore, since the sealed system eliminates hard water replenishment, it dramatically lowers on-site water quality requirements. Meanwhile, I configured an automatic water replenishment loop for our mould temperature controllers, introducing pre-filtered water only when necessary, thus maintaining water purity at all times and reducing maintenance burdens. This design choice prevents air entrapment, stabilizes thermal response, and prolongs pump life.

Maintenance Ensures Reliability at the Production Site

Proactive maintenance also improves the reliability of mould temperature controllers. Operators should inspect water tanks quarterly for discolouration, microbial growth, or conductivity spikes. Additionally, technicians replace filters on a strict schedule, and conductivity probes verify water integrity. Our training services team utilises hardness testers and digital conductivity testers to verify water quality, recording each measurement in our centralised maintenance database. This rigorous approach ensures that each controller operates to specification, prevents unexpected thermal cutouts or pump failures due to scaling or corrosion, and supports uninterrupted production in remote or challenging environments.

Ensure scale-free operation in areas with hard water

Teflon floats in the temperature controller for reliable level sensing, upgraded copper heaters for superior heat transfer, sealed deionised water circuits to prevent mineral deposits, integrated water tanks in water-type mould temperature controllers to stabilise water volume, and a strict maintenance regimen for continued protection. By implementing these combined solutions, you can prevent mould and rust, maintain precise thermal stability, and mitigate the effects of poor water quality.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2025/06/27

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2025/06/27

- Star Case | Topstar helps Santong upgrade its intelligent plant 2025/06/27

- Topstar Special | National Science and Technology Workers Day 2025/06/27

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC