Industry tends to be intelligent, Topstar helps Zhongtuo Precision to build an injection molding intelligent factory

2022/04/29 By topstar

Injection Molding Intelligent Factory

Nowadays, with the continuous improvement of national living standards, consumers’ pursuit of product performance has also been enhanced. 3C electronic products such as intelligent wear, wireless headphones, and audio are constantly updated and iterated, driving the growing market demand for the injection molding processing industry. When the rising labor cost pressures the business operation, more and more enterprises in the 3C industry choose intelligent upgrades and transformation. Dongguan Zhongtuo Precision Technology Co., Ltd. (referred to as “Zhongguo Precision”) is one of them.

“We choose the Topstar injection molding intelligent whole factory solution – TM series injection molding machines with robots, while equipped with ‘Topstar Link’ digital management system.” Tang Yangchun, chairman of Zhongtuo Precision, said, “After the intelligent upgrade, our labor cost is reduced by 50%, and production efficiency is increased by more than 40%.”

01 Intelligent upgrade, help production efficiency by 40%

As an essential partner of Topstar in the 3C industry, Zhongtuo Precision is a wholly-owned subsidiary of Jinleida, which has been deeply involved in audio-visual and digital electronic products for more than ten years. It mainly operates in designing, developing, producing, and selling 3C electronic products, such as audio, cell phones, and computers.

“Previously, our injection molding production part was outsourced. Not only was it difficult to control the product delivery time, but also the lack of quality assurance brought great resistance to the company’s development. So from 2021, we started to produce injection molding, hoping to achieve cost reduction and efficiency increase by creating an intelligent workshop.” Tang Yangchun said, “After multiple assessments, we finally chose Topstar to build an intelligent workshop for us.”

02 Get a good reputation with products and services

Topstar provided the then-latest TM series injection molding machine for Zhongtuo Precision in this solution. In 2020, Topstar entered the injection molding machine industry. Based on 30 years of injection molding machine technology in the original factory, the first TM series precision injection molding machine was developed independently. The clamping force of the TM series is 90-470 tons, with features of versatility, high performance, easy operation, digitalization, etc. A Servo motor is used, which can save more than 50% of energy. Moreover, the TM series has high response performance and can adapt to high-precision product manufacturing. The system is compatible with peripheral auxiliary machines and automation, which can realize integrated control and applies to many application scenarios such as 3C, home appliances, optoelectronics, auto parts, and medical and daily chemicals.

Reasons for choosing Topstar

Talking about the reasons for choosing Topstar, Tang Yangchun said, “First of all, Topstar has been deeply involved in the injection molding industry for more than ten years; not only has the injection molding machine and its supporting equipment and other hardware equipment, and digital solutions, can provide injection molding whole plant solutions and one-stop service, with high advantages in service and price. Secondly, I used to use the predecessor of the Topstar injection molding machine, the Elite machine; the performance and technology of this machine are very well understood, and I am a fan of it.”

“The more important point is the after-sales service. Buy equipment, after-sales service is essential. Topstar’s after-sales service is the most in place, so I feel excellent. Whenever the equipment encounters small problems, Topstar after-sales staff can always solve them for us in time to protect the production schedule. The sales responsible for this project is also very hard and dedicated.” Tang Yangchun said so. He recalled that after the equipment arrived at the factory, the production was urgent. Topstar’s sales and after-sales personnel rushed to the workshop to debug and install the equipment. Finally, he was very touched by the smooth start of production.

03 Digital transformation for more efficient management

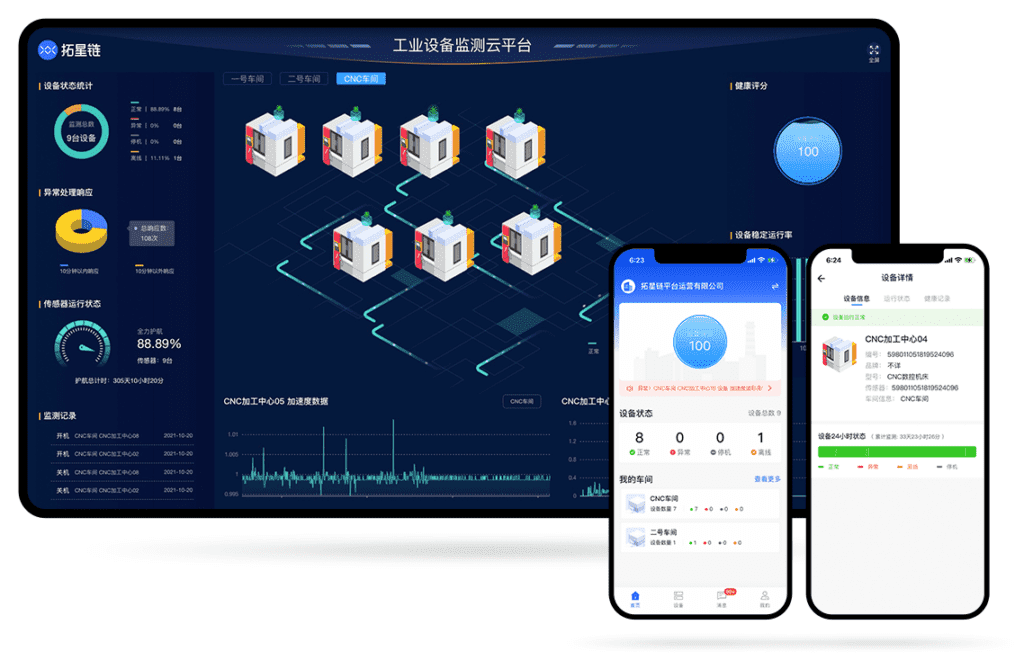

The focus of intelligent factory upgrading is not only the upgrading of hardware and equipment used in production. It also includes the factory’s digital capabilities. To improve the digital management level of small and medium-sized enterprise workshops and realize intelligent production. Topstar provides ZTO with a convenient digital factory solution, “Topstar Link.”

As a data product created by Topstar, the “Topstar Link” digital management system monitors vibration and other physical signals generated by equipment through an AI algorithm. To establish the equipment operation model and realize the all-weather seamless monitoring of equipment. And it has the functions of fault warning and record, one key to report repair. It makes equipment management more accessible and helps manufacturing companies avoid the secondary risk of equipment and reduce company loss.

More efficient and convenient management

“Now, no matter where I am, I can check the operation of each machine in the factory and the production situation through my phone. And the data is clear and crisp, so it is more efficient and convenient to manage.” Tang Yangchun feels very satisfied with this. The upgrading of intelligent factories has not only played a positive role in the production efficiency of ZTO Precision. It also brings more development opportunities. Tang Yangchun said that their software and hardware facilities had been completed. This will provide a strong guarantee for products to enter the overseas high-end market in the future.

At present, Topstar has formed a technically advanced, stable quality. Wide range of applications of injection molding overall factory solutions. Topstar will help more manufacturing enterprises achieve intelligent transformation and upgrading. Including 3C, home appliances, medical, new energy, daily chemicals, packaging, and many other fields.

This year is the fifteenth anniversary of the establishment of Topstar. Tang Yangchun to Topstar sent thanks and blessings. He smiled, “We are also fans of Topstar now.”He expects Topstar to develop more efficient, accurate, stable, and intelligent equipment to the industrial process requirements. And work together in the future to achieve mutual benefits and win-win results.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2022/04/29

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2022/04/29

- Star Case | Topstar helps Santong upgrade its intelligent plant 2022/04/29

- Topstar Special | National Science and Technology Workers Day 2022/04/29

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC