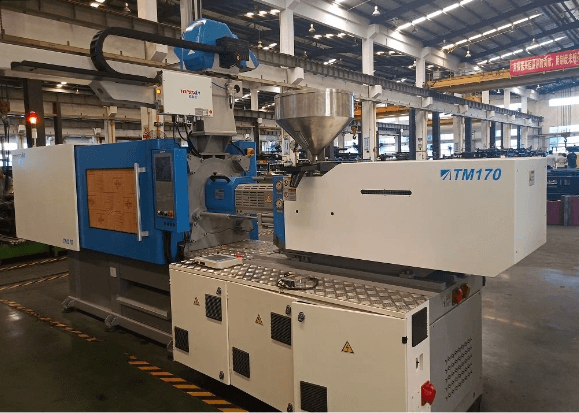

Plastic Injection Machine – The Choice for Efficiency and Flexibility

2023/09/08 By Topstar

In many manufacturing industries, people generally choose a plastic injection machine to produce plastic products for them because they maintain efficiency and flexibility, which is an excellent way to make high-quality products. Today, we will discuss their features besides efficiency and flexibility and why so many people like them.

Plastic injection machines are built for efficiency!

Plastic injection machines can significantly increase efficiency. These machines are designed to produce large quantities of high-quality products and do so in a way that ensures your production runs are as smooth and consistent as possible. This reliability is critical when thousands or even millions of products are manufactured yearly, which is why many manufacturers invest in plastic injection molding.

Because plastic injection machines produce parts so efficiently, their maintenance requirements are also accessible. Most pieces are easily replaced, making it easier for less experienced workers to keep the job running smoothly without having to do anything. Plus, there’s no need for expensive equipment upgrades!

Choose Plastic Injection Machines for Flexible Production Lines!

Choosing an injection molding machine as the core equipment of the production line can significantly improve production efficiency. The injection molding machine has the capability of rapid injection and cooling, which shortens the product’s production cycle, thus increasing output and production efficiency. Their ability to change molds enables them to adapt to producing products of different shapes, sizes, and materials. They can also adjust the injection machine parameters and decays as needed to meet the production needs of other products. They are also easy to change, so even those without much experience will find them easy to manage. Many companies choose this type of equipment, and these factors make your production line more flexible.

Plastic injection machines respond quickly to demand!

Plastic injection machines can respond quickly to demand. They can produce many products, including bottles, tubes, and more. Plastic injection machines can also create various shapes and sizes, from small containers to large storage tanks. The machine’s ability to create different colors allows manufacturers to offer customers unlimited options when choosing the product that best suits their needs. You can customize different product designs and specifications and take advantage of the flexibility of your injection molding machine for rapid production. This enables you to meet your customers’ individual needs, improving customer satisfaction and market competitiveness. Their versatility makes them more cost-effective than other manufacturing methods because they require less equipment or labor costs than other processes.

Plastic injection machines are also energy-saving and environmentally friendly!

TOSTAR’s plastic injection machine uses less electricity and requires less energy than other manufacturing methods. Modern injection molding machines generally use electric drive systems with higher energy efficiency and lower energy consumption than traditional hydraulic systems. The electric drive system can perform precise control, reducing energy waste and improving the energy utilization rate of the injection molding machine. In the context of increasing awareness of environmental protection, more and more companies choose to use environmentally friendly plastics as raw materials, such as degradable and recycled plastics. These environmentally friendly materials can reduce the consumption of natural resources and the carbon footprint of the production process and products.

They are a great and inexpensive way to get quality products!

Plastic injection machines are the best choice for large quantities of similar products. They are also ideal for small batches of custom products and suitable for your production line to ensure you get the best results. Plastic injection molding machines are a great, inexpensive way to produce high-quality products in any quantity you want! They have low equipment cost and maintenance costs and high production efficiency. Therefore, choosing an injection molding machine is an economical option to help companies reduce production costs and increase profits.

Delivering efficiency and flexibility starts now!

Through such an article, we can know more clearly that the plastic injection molding machine is a more efficient and flexible choice. In addition, Topstar has other equipment on the production line, which is also very important and compatible with plastic injection molding machines. Go to our website to learn more.

TRENDING POSTS

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC