7 Advantages of Small cnc machine for Beginners

2022/03/08 By Topstar

Firstly, to understand the operating principle of a small cnc machine, we first need to understand the structure of this machine. Ordinary small CNC machines design with processing capabilities that are not as powerful as industrial CNC machines.

However, it still ensures to process products with normal processing requirements. Not only that, when using this CNC milling machine, it also helps to reduce operating costs, does not take up warehouse space to place the machine, and at the same time, as well as, the use of the machine is simple, does not require too high professionalism.

What are the main Content of small cnc machine

- Construction of mini CNC milling machine

- Controller of mini CNC milling machine

- Sensor system

- Driver included on mini CNC machine

- Machine drive system

- Structure of the machine

- Servo motor

- Mini CNC machine spindle

What is the application of mini CNC milling machine?

Mini CNC milling machines are often known for their low investment costs, so users can buy them to perform simple milling jobs. However, some professional mini CNC machines can still process metal materials with precise results for manufacturing jobs.

To understand the working principle of a mini CNC milling machine, let’s first learn about the structure of the parts of this machine. Furthermore, Small cnc machine makes up of many different parts such as: controller, transmission mechanism, machine structure, software use, and spindle.

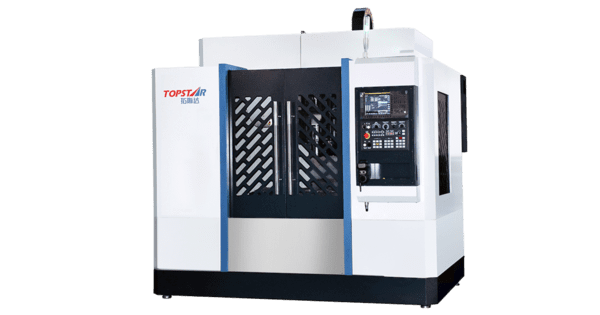

Overview image of mini CNC machine

The controller is considered one of the most important parts in the entire operation of this machine. It is the brain of the machine, each of these mini machines also design with different levels, there are machines with only a few million dongs, they use the GRBL open source code, so the cost is low and the operating mechanism is also quite simple.

For some more advanced machines, it uses in production, and small industry should use Mach3 controller. As for specialized machines in molds, which require high-precision products, they can use the same operating system as Fanuc made in China, including NC studio, Weihong, GSK, etc.

Sensor system of small cnc machine

Moreover, small cnc machine not equip with many sensors. Most of them use only open-loop drivers, but there are still a handful of new professional machines equip with close-loop drivers. Accordingly, components such as temperature sensor, motor shafts, and spindle speed measurement are all adjusted accordingly.

Driver included on mini CNC machine

Eventually, it depending on the type of motor equip on each type of milling machine, it will have appropriate drivers such as: driver for servo motor or driver for stepper motor. These motors often play a very important role on the machine, thereby having a great impact on the accuracy of the product when machining.

Machine drive system

Subsequently, it comes with low-cost mini small cnc machine; they are usually only equipped with a transmission designed with a slide with a regular lead screw. With this transmission system, it can only process soft non-metallic materials, but cannot uses to process metal materials. These types of machines often come with poor quality. After a period of use, this part will be bent, making loud noises and high errors.

High-quality mini-milling machines often equip with slide rails with ball screws for stable, smooth and high-precision operation. At the same time, it can process metal materials with high hardness such as aluminum, steel, stainless steel, etc.

Structure of the cnc machine

In addition, it comes with cheap mini machines that often use aluminum bars, further; the chassis is quite weak and uncertain. Small router machines are usually equipped with specialized aluminum sheets for non-metallic processing.

As for the high-prices mini CNC machines, usually a cast frame or steel part uses to make the body part sturdy. From there, it is possible to easily process all kinds of metal materials, improve quality and bring high efficiency.

Mini CNC machine equip with servo motor

With high-end mini machines are often equip with servo motors. Therefore, the small cnc machine price is usually relatively high, because it also has the ability to sense the position and speed, thereby helping the operator easily controls the operation of the CNC machine in the best way to help improve the accuracy of the machine.

CNC machine spindle

The average power of designed mini CNC milling machines ranges from 150W to 3.2 KW. The main shaft is also an important part in the structure of this machine. It plays a decisive role in the machining ability of the machine.

Only machines with good structure can be invested with a capacity of 1.5KW or more. With high-end machines, it will help sharpen the processing of a variety of different materials.

What is the application of mini CNC milling machine?

Hand-held machine mainly apply to the processing and manufacturing industries. This machine is capable of cutting and milling on many different material surfaces from metal to non-metal.

A small cnc machine can uses for cutting, milling, decorating product edges, drilling holes, grooving hinges, cutting grooves efficiently, etc. complexity and precision. This machine also designs with a compact size that can be easily held and carry for construction.

Also because the construction of a mini milling machine not too complicate, the process of using it is not too complicate. The products made from this type of milling machine are usually of excellent aesthetics and quality.

Common applications of CNC machines

Small cnc machine with a variety of models and sizes are suitable for machines that operate continuously and increasingly focus on quality as well as outstanding features, so CNC machines for application in the industry:

– Machinery Semiconductor;

– PCB assembly machinery;

– Medical equipment;

– Robotic arm machinery;

– Precision measuring machines;

– Compact automatic machinery;

Where to buy good quality, cheap CNC machine?

As a distributor of genuine and affordable CNC machine products and CNC components, when coming to the Machine Era, customers will feel

- CNC machines and CNC components should be of high quality, long service life, and good price.

- Support fast and convenient delivery nationwide.

- 100% brand new and genuine with CO / CQ certificates and 1 year warranty.

- After-sales mode makes customers feel satisfied

Eventually, the above article is some information share by Top star machine about mini CNC milling machines. Hope it has been really useful for those who are looking to use this machine. Hope you find a machine that suits your needs and purposes.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2022/03/08

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2022/03/08

- Star Case | Topstar helps Santong upgrade its intelligent plant 2022/03/08

- Topstar Special | National Science and Technology Workers Day 2022/03/08

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC