What assistance does the horizontal injection molding machine provide for your production?

2023/09/14 By Topstar

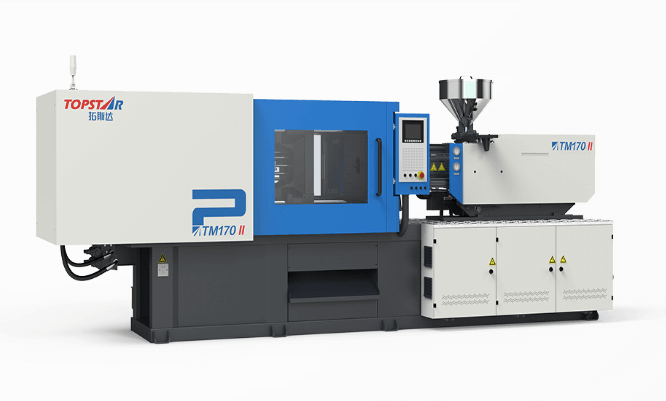

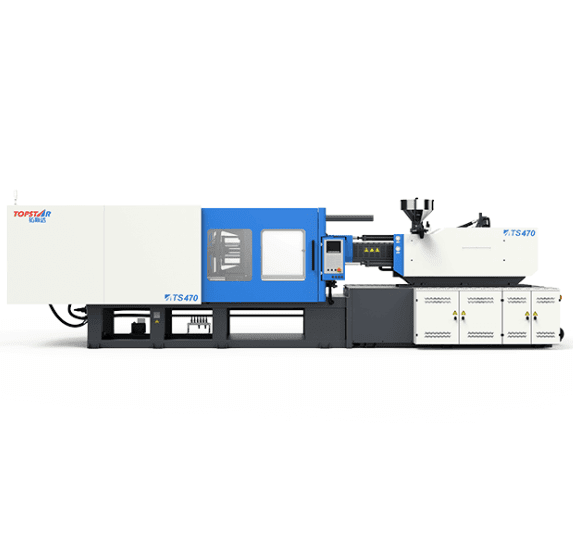

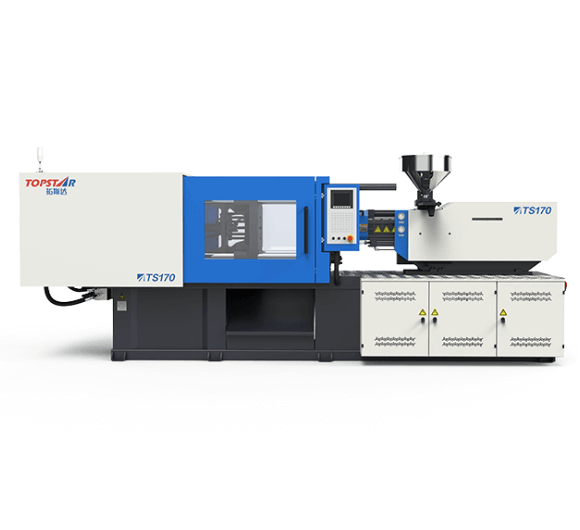

In today’s fast-paced manufacturing landscape, efficiency is the name of the game. Every production facility seeks innovative solutions to streamline processes and enhance productivity. One such indispensable tool in plastic manufacturing is the horizontal injection molding machine. This article will explore how horizontal injection molding machines provide invaluable assistance to production processes, delivering efficient, precise, and cost-effective results.

A Glimpse into the World of Horizontal Injection Molding

Horizontal injection molding machines are pivotal devices in plastic manufacturing. They operate on the principle of injecting molten plastic material into a mold cavity, allowing it to cool and solidify, resulting in a wide array of plastic products, from simple components to complex parts. This process is highly versatile and a cornerstone in numerous industries, including automotive, electronics, medical, and consumer goods.

Precision and Consistency

One of the standout features of horizontal injection molding machines is their ability to deliver precision and consistency in product manufacturing. The devices can maintain tight tolerances, ensuring that each molded piece meets specifications. This level of accuracy is crucial, especially in industries where even a minor deviation can lead to product defects or safety concerns.

Precision forming tolerance:

These machines operate with extraordinary precision, ensuring that each molded part strictly adheres to the specified tolerances. They provide accuracy similar to skilled artisans’ skills but have the advantage of high replicability. This aspect is essential in the aerospace and medical devices industries, where even minor changes can have significant consequences.

Eliminating variability:

Unlike some traditional manufacturing methods, horizontal injection molding machines eliminate variability in the production process. Each cycle is the same, resulting in consistent product quality, reduced rejection rates, and improved customer satisfaction.

Complex geometric shapes and intricate details:

Manufacturers typically rely on horizontal injection molding when producing components with complex geometric shapes and details. These machines excel at replicating complex features with excellent fidelity, such as fine text, microstructure, or precise undercutting. Whether medical equipment with complex contours or automotive components with demanding specifications, these machines meet challenges with unwavering precision.

Tooling and mold accuracy:

Coordinate the horizontal injection molding machine with carefully crafted molds. The design accuracy of the mold itself is extremely high, and cutting-edge technologies such as CNC machining are usually used to ensure its accuracy. Combined with the precision of the molding machine, the final product has achieved an extraordinary level of accuracy.

High Production Efficiency

Efficiency is the hallmark of horizontal injection molding machines. Their automated and continuous operation minimizes downtime between cycles, resulting in high production output. This efficiency reduces labor costs, shorter lead times, and increases competitiveness for manufacturing companies.

Versatility and Adaptability

Horizontal injection molding machines offer versatility and adaptability, accommodating various materials and product designs. Whether you need to produce intricate and small components or large, complex parts, these machines can be customized to suit your specific requirements. This adaptability is crucial for manufacturers operating in dynamic markets with evolving product demands.

Horizontal injection molding machines are suitable for many industries

This injection molding machine can be used for liquid filling and spraying mixed products, such as food packaging, cosmetic packaging, pharmaceutical packaging, toys, household appliances, and other products that require repeatable, high-quality performance.

Plastic injection molding machines are widely used in food because they are suitable for producing various packaging materials that meet national standards. In addition, they have good cost-effectiveness compared to other methods, such as hot forming or rotary forming.

For example, if you want to produce plastic cups with openings on both sides (like those used in fast food restaurants), you will need two machines – one on each product side! However, if you only need a simple single-sided cup (like most homes use), you only need one!

Injection molding machines make it possible to use low-cost materials such as PET

Low-cost materials such as PET can be used without sacrificing product performance.

It makes it possible to produce various products with high precision and high quality, from small to large.

Injection molding machines with size, cycle time, and batch size limitations can be used for large-scale or small-scale production.

Cost-Effectiveness

Cost-effectiveness is a primary consideration in any production process. Horizontal injection molding machines help manufacturers achieve cost-efficiency in several ways. Firstly, their high productivity reduces the need for extensive manual labor, cutting down on wage expenses. Their precision and consistency also minimize material wastage and the likelihood of producing defective parts, ultimately saving on raw material costs.

Automation and Integration

The modern horizontal injection molding machine is equipped with advanced automation features. These machines can be seamlessly integrated into an automated production line, reducing the need for human intervention and enhancing overall process efficiency. Automation speeds up production and minimizes the risk of errors associated with manual operation.

Horizontal injection molding machines are becoming increasingly indispensable.

Horizontal injection molding machines are the unsung heroes of modern manufacturing. Their precision, efficiency, versatility, and cost-effectiveness make them invaluable assets for businesses across various industries. In a world where competitiveness hinges on productivity and quality, these machines play a crucial role in ensuring that manufacturers meet the demands of their customers while maintaining profitability. As technology advances, horizontal injection molding machines are poised to remain at the forefront of the manufacturing revolution.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2023/09/14

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2023/09/14

- Star Case | Topstar helps Santong upgrade its intelligent plant 2023/09/14

- Topstar Special | National Science and Technology Workers Day 2023/09/14

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC