What is the indispensable role of injection robots in the injection molding industry

2023/10/16 By Topstar

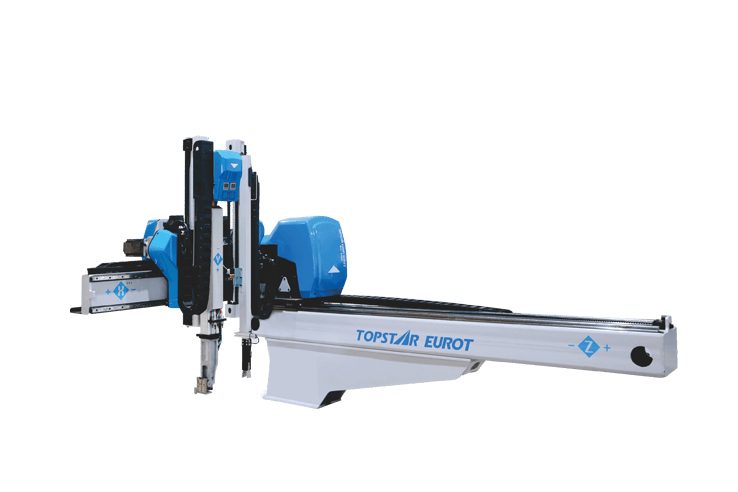

Every process is crucial in the entire production process of the injection molding industry. The injection molding machine is an essential equipment in this industry. Today, we will share the most indispensable role of injection robots in this environment and understand how they cooperate with the injection molding machine. These technological marvels ushered in a new era and redefined the manufacturing landscape with their indispensable role. With the changes and developments in the industrial environment, people need higher precision, efficiency, and reliability of industrial equipment.

The indispensable precision of injection robots

Precision is the cornerstone of injection molding and cannot be compromised. Injection robots are equipped with state-of-the-art automation technology, taking precision to another level. Reduce power consumption by 10%, increase overall line speed by 20%, and increase maximum lifting capacity by 20%. Their ability to perform parts removal, insertion, and secondary operations with unparalleled precision sets new industry standards. The collaborative capabilities of injection robots ensure that every product is manufactured with error-free precision, seamlessly complying with the industry’s stringent requirements. Their accuracy is astonishing. With advances in robotics and sensors, these machines can consistently place, remove, and process parts with minimal deviation. This level of precision is critical to the industry, and by automating these processes, injection molding robots have become the guardians of accuracy in injection molding.

Injection robots are the core of production efficiency!

In the field of high-speed, high-precision injection molding, efficiency comes first. The introduction of injection robots has significantly reduced cycle times, expanded production capabilities, and maintained unwavering consistency throughout the manufacturing process. High-performance AC servo motors drive them and have good high-speed grabbing performance to increase efficiency. These robots are central to meeting the industry’s rapid turnaround needs, making them an indispensable asset for manufacturers aiming to increase productivity. Efficiency is the primary goal, and injection molding robots excel at fast, repetitive tasks, ensuring molds cycle through each process with minimal downtime. Increased efficiency benefits manufacturers by growing output and reducing operating costs, translating into higher profits and a more competitive market position.

Injection robot leadership sign

Versatility is the hallmark of any industry leader, and injection robots embody this trait perfectly. Their ability to seamlessly integrate into various molding machines and processes underlines their presence in different production environments. Whether insert loading and unloading, over-molding, or assembly, these robots can perform numerous tasks, proving their efficacy and adaptability. Plus, their versatility extends to the wide range of industries they serve. In addition to their role in traditional plastic injection molding, they are used in areas as diverse as medical device manufacturing, electronics, automotive, and even food production.

Optimize resources for maximum impact!

In addition to precision and speed, injection robots revolutionize resource optimization. Taking over repetitive and labor-intensive tasks allows it to focus on the more complex aspects of molding operations that require problem-solving skills and decision-making. In this way, injection robots provide a comprehensive solution to the industry’s long-standing resource allocation challenges. Optimizing resources extends to labor and time management. Manufacturers can deploy their workforce more strategically, and skilled workers are freed from monotonous and physically demanding tasks, allowing them to focus on robot programming, troubleshooting, and overall process management. This optimized allocation of resources ensures that all aspects of the production process benefit from human expertise.

Prioritize security and compliance!

Safety is non-negotiable during manufacturing, and Injection Robot takes this responsibility seriously. These machines have advanced safety features to protect workers and production processes. Complying with safety standards and regulations is critical in the industry, and injection robots can give manufacturers the assurance and peace of mind they need. Safety features are a fundamental aspect of their design. From enclosed work areas to advanced sensors that can detect human presence and adjust operations accordingly, these machines prioritize the safety of the manufacturing process and the people involved. This commitment to safety ensures compliance with industry regulations, reduces workplace accidents and injuries, and increases overall efficiency.

Brief summary

The injection molding industry is one of the leading industries in the country, in which injection molding robots play an indispensable role. Their core attributes include precision, efficiency, versatility, and safety, forming the basis for the industry’s future. As injection molding advances, these machines remain at the forefront, shaping the industry’s future.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2023/10/16

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2023/10/16

- Star Case | Topstar helps Santong upgrade its intelligent plant 2023/10/16

- Topstar Special | National Science and Technology Workers Day 2023/10/16

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC