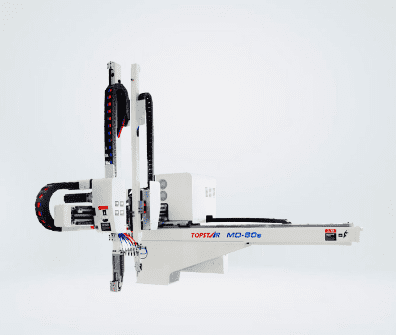

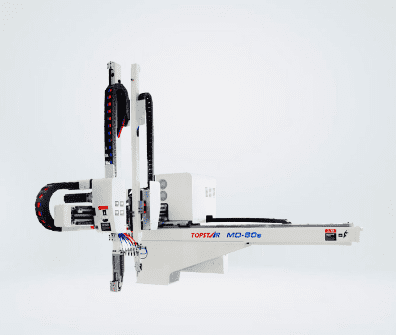

Injection Moulding Robots

Injection molding machines are used for plastic injection, a prevalent type of molding. And Injection molding robots use a kind of technology called Robots-As-A-Service (RaaS). This technology allows users to deploy robots quickly and easily in their facilities.

Definition of injection molding robots

Injection molding robots are used in the production of plastic parts. The main features of an injection molding robot are a tool changer, a palletizer, and a robot arm that picks up and places the molds onto the palletizer.

The tool changer is the part of the injection molding robot that changes tools on a conveyor. The palletizer then places the molds onto a pallet for storage or shipment.

What are the types of injection molding robots?

Single-shot injection molding robots

Continuous injection molding robots

Injection molding robots are used to automate the injection molding process. The robot loads the feedstock material into a hopper, which feeds it into a machine that melts and injects the material into molds before cooling down and ejecting completed parts from the mold.

How injection molding robots work

An injection molding robot is a machine that moves the injection molding machine. It does so by moving the robot arm, which has a drive shaft connected to it. The drive shaft is connected to an external gearbox and electric motor.

The injection molding machine contains all its gears and other parts inside it. This means that they must be made out of metal, so they don’t break during transport or while being transported here from there. This also means no moving parts between you and your finished product!

Injection molding machine and injection molding robot

Injection molding machines and injection molding robots are two different types of machines. An injection molding machine is used to produce plastic parts, while the injection molding robot is used to make plastic parts.

The advantages of Injection Moulding Robots

Injection Moulding Robots can help reduce the cost of labor and time to produce a product and improve the efficiency of your production process.

Cost: Injection molding robots are expensive, but they will pay for themselves in less than two years.

Time: It takes longer to program an injection molding robot than for a person because so many variables are involved. However, these machines can run 24 hours daily without breaks or holidays once programmed. Making them much more efficient than humans who need breaks and vacations!

The advantages of Injection Moulding Robots

Speed: The robot works at a very high speed and can quickly produce large quantities of parts. In contrast, the manual process is slow because it involves many human operators who need to be switched between different tasks.

Precision: The injection molding robots can produce precision parts with tight tolerances and high-quality finishes because they are equipped with sophisticated sensors that ensure accurate positioning during the entire process. In addition, you can use these machines for mass production. Saving on labor costs and material wastage that may occur during manual operations (such as scrap pieces).

Reduction of defects: There is no human error when using these machines. Therefore, compared with traditional methods (such as handmade items), the possibility of defects such as cracks or warpage is slighter because artisans may not have enough expertise in their respective fields.

Cost savings: Compared with traditional methods, robots are cost-effective due to the lack of the required skill level and the lack of experience gained from working under pressure for many years. Errors may mean the loss of valuable time spent waiting for the shipment of new materials, etc…

In general, it has many advantages.

Injection molding robots are a great way to improve your manufacturing process. They can help reduce costs, improve efficiency and increase productivity. In addition, they allow you to produce quality products at a lower price than before because the robots do not need human intervention during operation.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2023/01/31

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2023/01/31

- Star Case | Topstar helps Santong upgrade its intelligent plant 2023/01/31

- Topstar Special | National Science and Technology Workers Day 2023/01/31

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC