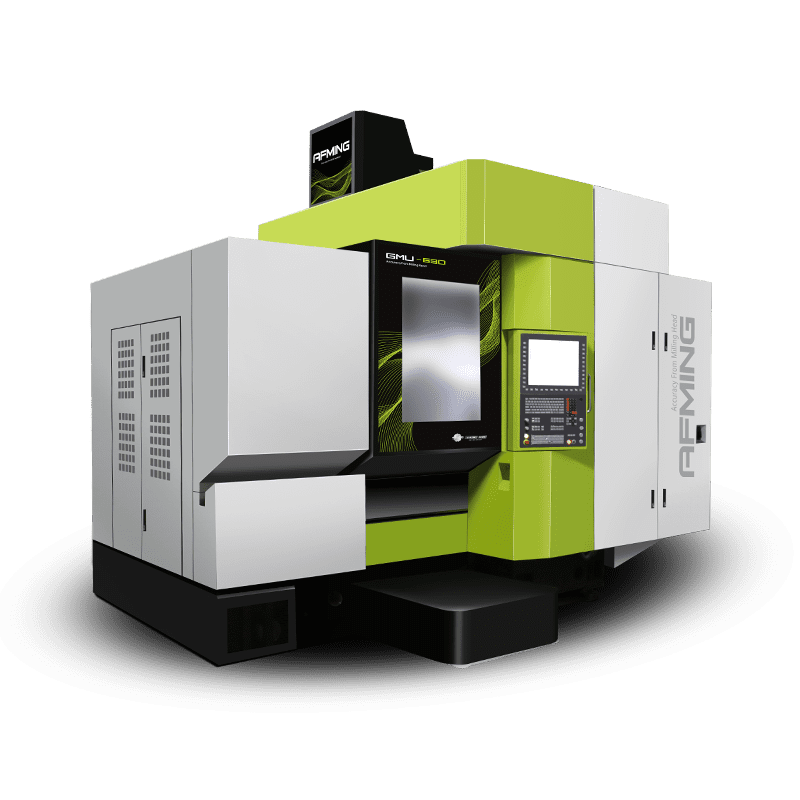

Why 5 Axis CNC Machining Center is Essential for Complex Parts?

2022/08/13 By Topstar

5 Axis CNC Machining Center (also known as a 5-axis Machining Center) removes materials from a workpiece using various cutting tools. It performs this process by synchronously cutting the material along five separate directional axes until the required shape is obtained.

5 Axis Machining Center can considerably increase your productivity and profitability. It elevates your production capabilities too.

How Does the 5-Axis CNC Machining Center Perform its Function?

Using 5-axis CNC machines, the parts can be placed in optimal alignment with the cutting tool (90 degrees). All five sides of a component can be reached simultaneously.

Utilizing all five axes allows for the simultaneous machining of even the most intricate contours and shapes.

A radial drilling machine, which moves up and down, would illustrate a 1-axis machine in more detail. Likewise, a CNC 3-Axes Machine can travel up and down, to and fro, and right to left.

Two more rotary axes on a 5-axis CNC machine provide access to an endless array of milling options. Rotating axes A, B, and C, which revolve around the X, Y, and Z axes, respectively, are examples of rotary axes. Even though there are only three additional axes and not two, the total number of axes is still five. Machine-dependent, the other axes can be combined in any way, including AB, AC, or BC.

The additional axes allow for undercutting, which was previously only possible on machines with fewer axes if the part was repositioned using extensive fixtures. A 5-axis CNC machine avoids situations that are not only time-consuming but also potentially error-prone in machines with fewer axes.

Advantages of 5-Axis CNC Machining Center

Here are a few advantages of 5 Axis CNC machines and 5 Axis CNC Machining Centers.

Reduced Machine Installation

A single setup procedure can reduce preparation time and boost human and machine productivity. It lessens the number of setups needed for each machining stage, which increases the risk of human and mechanical errors. The less complicated clamping apparatus used to position the part in the necessary location in the machine also saves time and money and lowers the possibility of errors.

Achievable Forms & Shapes

Complex forms and patterns can be easily handled using 5-axis machining. Injection molds, oil & gas equipment, medical or blood transfusion equipment, hydraulic system components, water pump housing, gearbox housing, gear wheels, and many other items may fall under this category.

Greater Machining Precision

The total precision of the generated product can be increased by using 5-axis CNC machines because fewer human settings are needed.

Improved Surface Finish

A 5 Axis CNC Machining Center enables optimal cutting conditions at any moment by allowing the cutting tool to move closer to the workpiece and be positioned 90 degrees from the part surface.

Shorter cutting tools with less vibration are made possible by the fourth and fifth axes (the rotational axis), which leads to an improved surface finish. The primary goal of the different axis is to improve the precision with which the cutting tool can access the part’s five sides.

Time Savings

It is becoming more and more crucial to examine operation and labor expenses. The operator does not have to re-clamp the part and transfer it to a different machine for subsequent operations. Because this machine has an integrated setup, they may concentrate on overseeing more machines, boosting their output.

Cost Effective

The increased accuracy of the 5 Axis CNC Machining Center reduces the possibility of expensive errors or scraps. Cost-saving benefits from 5-axis CNC machines include more flexibility and spindle usage. A reduced need for pricey fixtures and cheaper overall inventory investment.

5 Axis CNC Machining Center Increase Production Flexibility and Factory Capacity

The versatility of your productions will increase if you purchase a 5 Axis CNC Machining Center, which is ideal for the part and contract manufacturers. This tool lets you get the most out of your equipment for big and small manufacturing orders. With less expensive standard machines with obviously limited capabilities, such capabilities might not be present.

Additionally, 5-axis CNC machines are perfect for today’s High Mix – Low Volume manufacturing environment. Favoring delivering manufactured parts in smaller batches that can be repeated as needed rather than bulk production.

How to Set Up a 5-Axis CNC Machining Center?

A 5 Axis CNC Machining Center does not require complicated fixtures or clamping mechanisms to hold the part being produced. As a result, setting up a workpiece on such a machine is relatively simple.

The retaining device or component of the workpiece should ideally be installed in the middle of the machine table. A zero clamp vice, a hydraulic clamp. Or just a block with the component to be machined securely fastened might serve as the holding apparatus.

More importantly, the component must be securely fastened so that it cannot move or vibrate and be freely accessible to the cutting tool from all five sides. The next step is preparing, measuring, and putting the cutting tools and tool holder into the machine’s Automatic Tool Changer (ATC) magazine.

Before manufacturing begins, the entire machine must be calibrated. A crucial step that is sometimes missed. A particular software and an automatic measuring probe are needed for this calibration (either by infrared or radio). Depending on the machine type and manufacturer, the calibration process could take as little as 45 seconds or as long as 2-3 minutes.

Running such a calibration cycle ensures that the machine’s axes are all accurately calibrated and that no tolerances have been built between them. It must be carried out at least once each month, ideally once weekly, and unquestionably just before each production run.

Conclusion

In the World of Production and Manufacture, the 5 Axis CNC Machining Center has vast applications. One cannot negate the significance of such a tool if you are planning to buy CNC Machine or any product regarding CNC machines. Topstar will be a cost-effective option. Every device and mechanism is designed to save time and bring high efficiency.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2022/08/13

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2022/08/13

- Star Case | Topstar helps Santong upgrade its intelligent plant 2022/08/13

- Topstar Special | National Science and Technology Workers Day 2022/08/13

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC