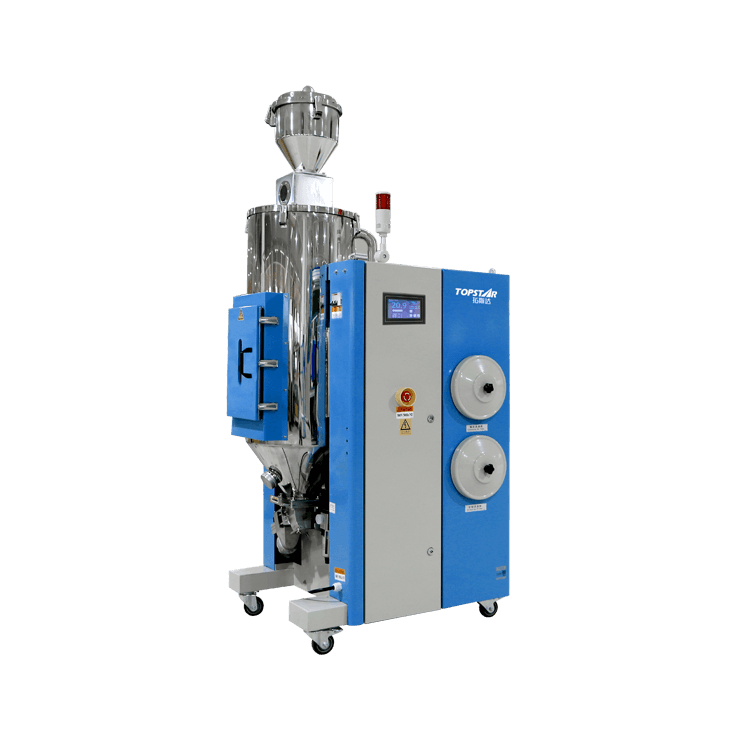

A dehumidifier dryer, also known as a desiccant dryer or DX machine, is a device that removes water from the air. It uses low-temperature heat to remove moisture from the air and then dries it back to its original condition. The process is similar to a refrigerator in the kitchen, but with a twist: Dehumidifier dryers can run continuously while refrigerators cannot. The continuous operation of dehumidifier dryers enables manufacturers to use them in industrial applications, such as drying plastic resin pellets or foods such as beef jerky.

Dehumidifier dryer is popular with manufacturers due to the following:

Dehumidifier dryers are suitable for drying food, textiles, and paper. The user can control the temperature of these machines, and they work well for drying materials that need to be humidified before packaging or storage.

Dehumidifier dryers can reduce the humidity in the air, which is the daily use of dehumidifiers. They must minimize moisture levels after cleaning up spills or leaks from boilers, cooling towers, etc. It’s important when using this type of equipment, though, as not all types of equipment are equally effective at removing all traces of moisture from surfaces, so make sure to buy equipment specifically designed for these purposes!

Dehumidifier dryers have additional timers!

The timer allows you to set the drying time, which is done by:

Within a specific time. This option allows you to specify how long the dryer will run regardless of how many cycles it takes. For example, if you want your clothes to dry in one hour, select “1 hour” from the timer screen and press OK. At this point, the machine will start running automatically until everything is dry.

A dehumidifier dryer is a device that removes moisture and then dries it to its original state!

A dehumidifier dryer is a device that removes moisture from the air and then dries it to its original state. Dehumidifiers are suitable for residential, commercial, and industrial applications for some reasons. In homes, they can help control humidity levels in the summer when you’re trying to save on energy costs by keeping your A/C system running at peak performance levels. They also help reduce mold growth and mildew on indoor surfaces like walls or window sills.

Dehumidifier dryers are safe to operate!

Safety Features: Desiccant dryers have built-in safety features that help prevent accidents while using them. For example, some models have an automatic shutdown feature that turns off the power if the internal temperature rises above recommended levels. Others may have overheating sensors or automatic restarts after a power outage, which help prevent fires caused by overheating motors or electrical shorts.

Furthermore, the desiccant dryer complies with European safety and quality standards. Protection against overheating and overloading of the device thanks to the materials of manufacture, thoughtful design, and the presence of sensors and warning systems. Its unit power switch is outside, so it is not subject to critical loads. Subsequently, it is located in the personnel passage area. In an emergency, use a quick manual shutdown of the device.

The dehumidification dryer is a low-cost and easy-to-use machine!

A dehumidifier dryer is a low-temperature drying machine with low operating costs and convenient applications.

Dehumidifiers use refrigeration to cool the air below the dew point, condensing the water vapor into liquid form. The resulting moisture is collected as droplets on the cooling coil or collection pan. This process is called desiccant drying because it uses desiccant material to absorb moisture from the air by adsorption rather than liquid water into a porous material.

The advantages of using a dehumidifier include fast drying time, easy installation/maintenance, low-temperature process, high efficiency, etc.

Final

All in all, we’ve seen that the dehumidifier dryer is a great product. It has many uses and can help you in many ways. If you are considering buying one for yourself or others, we also provide its corresponding features and application range here; choose the suitable product according to what you know!

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2022/05/11

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2022/05/11

- Star Case | Topstar helps Santong upgrade its intelligent plant 2022/05/11

- Topstar Special | National Science and Technology Workers Day 2022/05/11

HOT TOPIC

- .ervo motor-driven linear robots

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 2

- 21

- 23

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 5-axis CNC machine

- 62

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- injection moulding machines

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection moulding machines

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar