How to control Hopper receiver? Beginner Guide

2022/05/11 By Topstar

WHAT IS A HOPPER DRYER AND ITS APPLICATION?

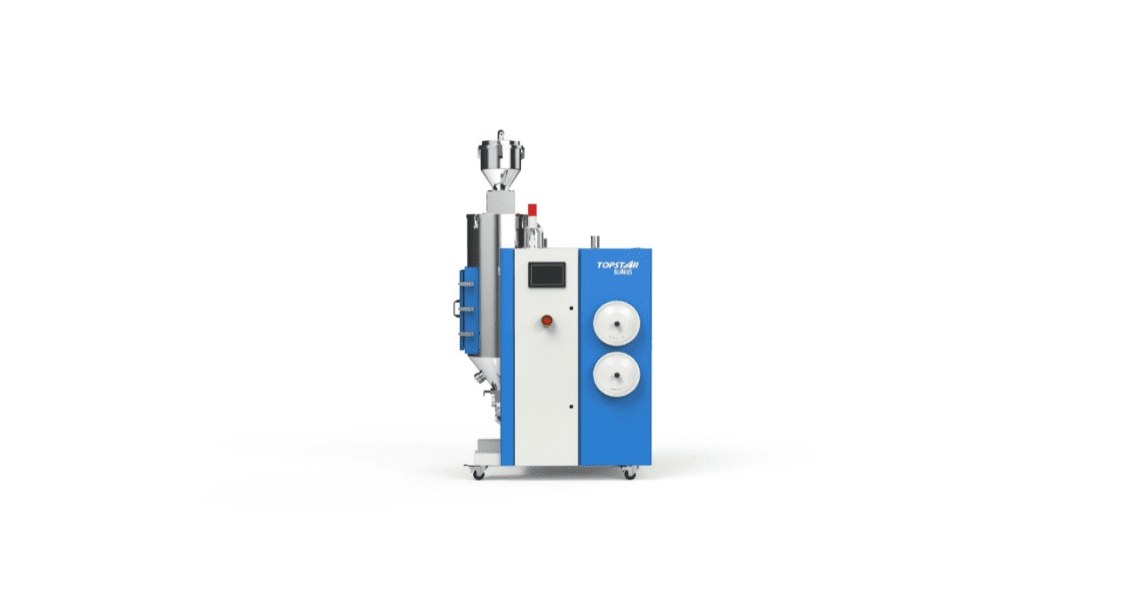

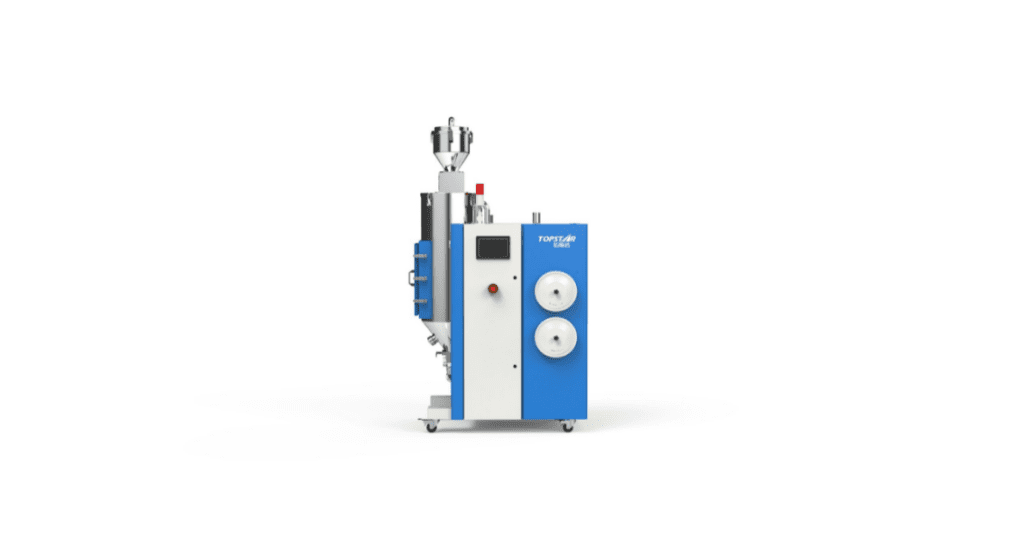

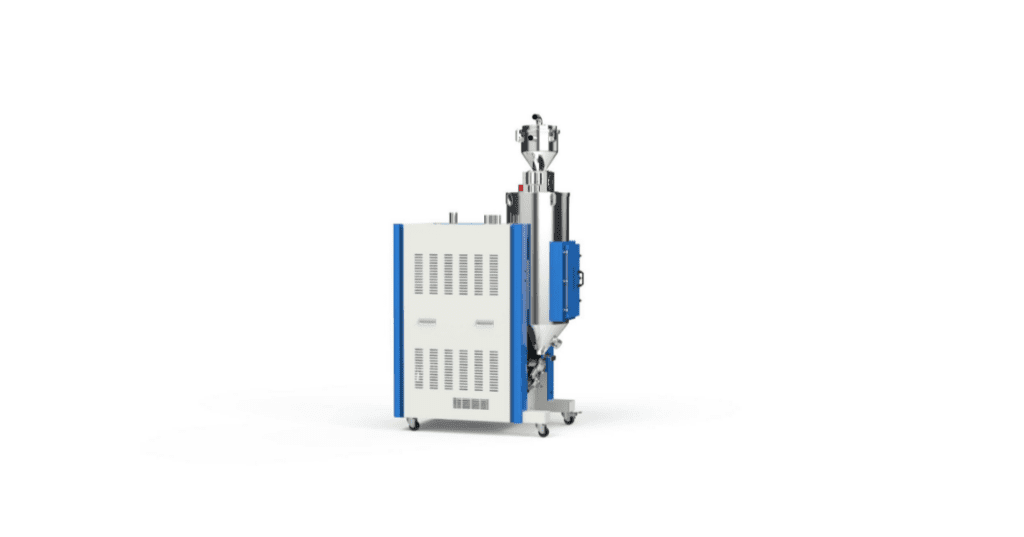

Firstly, the hopper receiver for processing plastic granules has a large cylindrical container with a cone-shaped bottom. The lower element of this form allows you to install the unit directly on the injection molding machine or extruder so that the dried polymer is sent straight to the next production stage.

The unit supplies a control system with a digital display. Although it often works automatically, you can further adjust the settings. The material is placed into the hopper through the top opening, which closes with a lid. You can watch the drying process through a unique viewing window.

What is the drying bin for?

Since plastic granules absorb moisture from the environment, it is necessary to use a hopper receiver beforehand to obtain high-quality plastic products without defects. Then, at the output, the polymers will have a uniform structure and color; they will receive the planned shape and other necessary characteristics.

The hopper receiver works as follows. When polymers load from above, hot air supplies from below, which evaporates moisture from the surface of the granules. Due to the cylindrical shape of the device, the material evenly distributes and effectively dries.

How does the hopper receiver work?

During the drying process, dust and other foreign particles may enter the hot air. Therefore, the unit equips with a filter to capture them. Further, the air that fulfills its tasks enters the cooling chamber, where moisture settles in the condensate.

And the airflow is sent back to the heating compartment, and the cycle repeats. So there is a continuous processing of raw materials.

While the first batch is ready for the next step and is sent to the machine, the next portion can already be fed from above. This approach allows you to organize continuous high-performance production:

Moreover, a high-quality bunker plant hopper receiver can work in intensive mode for a long time. Since plastic is sensitive to high temperatures, it should ensure that the temperature of the hot stream for drying does not exceed 70-80 degrees. Then the granules will not melt ahead of time.

Benefits of using a dryer

Hopper receiver in production if, in the production of plastic products, granules that accumulate moisture use without prior drying, the risk of rejects significantly increases. Products may become cloudy.

Pores and cavities will be in the walls, and strength and physical and mechanical properties will be critically low. It also threatens increased foaming during the casting process, which can spoil a batch of goods and disable expensive equipment.

Dry granules perform better in the production process because the hopper receiver provides a higher injection rate of liquid polymer into the mold. This has a positive effect on all aspects of production. Therefore, we recommend that you choose a suitable unit from our assortment: it will help you make the right choice depending on your work tasks.

Different types of polymers

In the production and processing of different types of polymers, the technology requires their preliminary drying. For granulated raw materials, different types of dryers use:

- Modular dryers;

- Bunker dryers;

- Insulated drying bins;

- Drying chambers.

Drying is chosen based on the initial data:

1. What should be the air supply;

2. Necessary performance;

3. Required number of bunkers;

4. Hardware configuration.

In case of overheating, the workflow automatically stops. Also, the hopper receiver can equip with a timer and a magnet (but this already depends on the model).

Bunker dryers are a reliable and easy-to-operate device

The main elements are a fan, a receiving compartment, and a heating device. Additionally, dryers can equip with thermal insulation. The control unit consists of a temperature controller and a safety device.

Modular raw material dryers are flexible, precise, and stable in operation. Maintenance of equipment can carry out without stopping it.

Modular dryers have automatic self-tuning of the airflow and an anti-stress system for polymer raw materials. They are also very convenient and easy to use (just set the material and productivity).

Differences between bunker dryers and drying cabinets

- Drying cabinets differ in manual loading/unloading of raw materials. Bunker dryers can be completed with automatic loaders.

- Drying cabinets allow you to dry several types of polymeric materials. The Hopper receiver is only suitable for one kind of drying at a time.

- The drying cabinet installs as independent equipment. Bunker dryers can install on the injection molding machines, extrusion or other equipment;

- Prepared products from bunker-type dryers can be immediately sent for further processing, while drying cabinets do not have such a function.

A plastic dryer is considered almost necessary specialized equipment to dry plastic materials quickly. In particular, thanks to many outstanding advantages, the plastic hopper receiver is the leading effective solution to help optimize productivity and profit for plastic enterprises.

1. Hopper receiver Specifications

A plastic drying hopper or plastic dryer is a specialized machine used to effectively dry or dehumidify plastic materials, especially waste plastic, before transferring materials to the following stages.

Depending on your needs and production plan, you can choose the plastic dryer models with the corresponding capacity. Below are the specifications of the plastic drying hopper receiver models:

2. Product features

- Using a fan with high heat dissipation keeps the dry temperature of the material uniform, thereby increasing the drying efficiency.

- The hot air duct has an intelligent design, which helps to avoid being pushed to the bottom of the electric heating tube to cause a fire.

- The inside of the hopper receiver and components are all made of high-quality, durable stainless steel.

- The material tank and the part below optimally designed can separate from each other, making it easy to clean and change the material quickly.

- Using an advanced controller to display accurate temperature.

- The plastic drying hopper equips with an over-temperature protection device, which helps to reduce unintended machinery breakdowns.

What is the difference between plastic hopper receivers and other equipment on the market?

Impressive productivity

The plastic drying hopper receiver can dry at a maximum temperature of 120 degrees Celsius (or higher depending on customer needs) and uses a cooling fan to keep the internal temperature uniform, thereby helping to dry plastic granules quickly, effectively improving productivity compared to manual methods.

TRENDING POSTS

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC