Take Advantage of Desktop CNC Machine: 9 Tips

2022/03/24 By Topstar

Regarding production activities in the mechanical engineering industry, an indispensable device is a desktop CNC machine.

What is a CNC machine?

CNC machines are a standard mechanical device widely applied in the mechanical industry. Especially in the mechanical sector manufacturing gas. So, do we have a good understanding of CNC machines? How does it work, and how does it work? So here we go to learn about CNC machines.

Main Table of Contents

- CNC Definition

- What is a CNC machine?

- Applications of CNC machines

- Working principle of CNC machine

- Advantages of CNC machines

- Conclude

What is CNC?

The purpose of CNC is to support the processing of all kinds of mechanical products to improve productivity, as well as improve product quality and accuracy and reduce human effort.

As we know above, desktop CNC machine refers to the operation and control via computer, so CNC machine means processing machinery that uses technology to control fully automatically via computer. Therefore, CNC machines can work in many different spaces such as 2D, 3D,…

The machine will manage and manipulate the system to move in any direction based on the system’s control. Computer or specialized equipment. The CNC machine will ensure more accuracy and comprehensiveness than traditional cutting machines that can only handle fixed shapes.

Applications of desktop CNC machine

The demand for CNC machines in Vietnam is now huge, from individuals to large enterprises, with the development of society and high requirements for aesthetics and the sophistication of dishes.

Metalwork, or even wood or mica materials, are required to create fine textures because that requires more specialized equipment than a traditional machine. Some of the applications include the following:

- Machining machine parts, metal molds,,

- Processing, depicting shapes, 2D, 3D patterns, …

- Engrave detailed designs on metal, wood, and mica,…

- Processing, carving, and shaping crystal, glass, stone glass, …

The application of desktop CNC machines is relatively high and widely standard, especially in the manufacturing industry. CNC machines help reduce the product finishing process and increase the ability to shape complex details to diversify human creativity.

Working principle of CNC machine

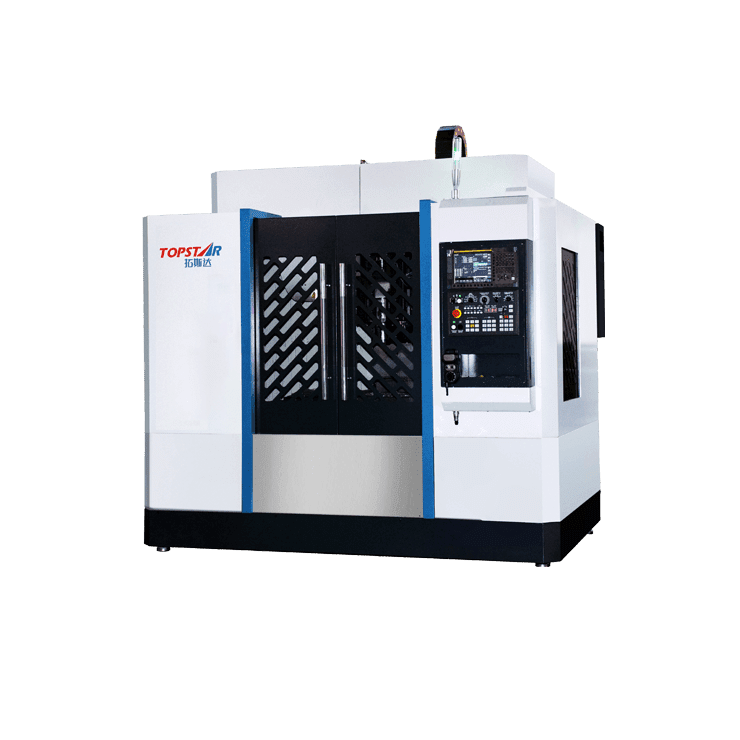

CNC machines have many different types and different uses and suitability, including several devices such as lathes, milling machines, planers, engraving machines, etc.

They all have one feature that all work on the general principle. The main shaft will move in the z direction from the top, and the table holds the product in the X and Y axes, bringing the cutting edge to all product surfaces.

When using a desktop CNC machine, the lines will produce very smooth and delicate products. Operating a CNC machine is not as complicated as many people think. Usually, before handing over the machine, the engineering team will guide you carefully from the most straightforward steps. After a short time, you can completely operate this machine.

Advantages of CNC machines

The application of CNC machines in processing metal parts or processing materials is very diverse. We can see a lot of advantages of CNC machines that perhaps cannot fully explain. They can be accurate. But in general, we can see some benefits of desktop CNC machines:

- Can cut magnetic and non-magnetic materials.

- Processing on all different materials: metal, non-metal, plastic, aluminum, stainless steel, and paper cutting.

- Cutting with a Fiber Laser is completed in less time than conventional cutters require.

- Able to work in air, vacuum, liquid, solid… There are many unique applications that no other technology can do.

- Cutting technology produces finished products without the need to reprocess the product, helping to maximize production costs.

Laser cutting technology reduces contamination of metal workpieces, providing specific advantages compared to traditional mechanical cutting techniques.

In the normal cutting process, the heat generated during the cutting process in a desktop CNC machine often easily deforms the product. While using Laser cutting technology because the heat-resistant area is tiny. It will reduce the possibility of metal warping and deformation.

- It can be cut to any straight or curved, thick and thin surfaces, intricate details…

- No noise, good working conditions. In addition, the working conditions of workers are greatly improved due to the lower amount of smoke and dust compared to mechanical methods.

- Good quality and affordable when using CNC machining, stainless steel processing, and stainless steel processing on demand.

General information about desktop CNC machine

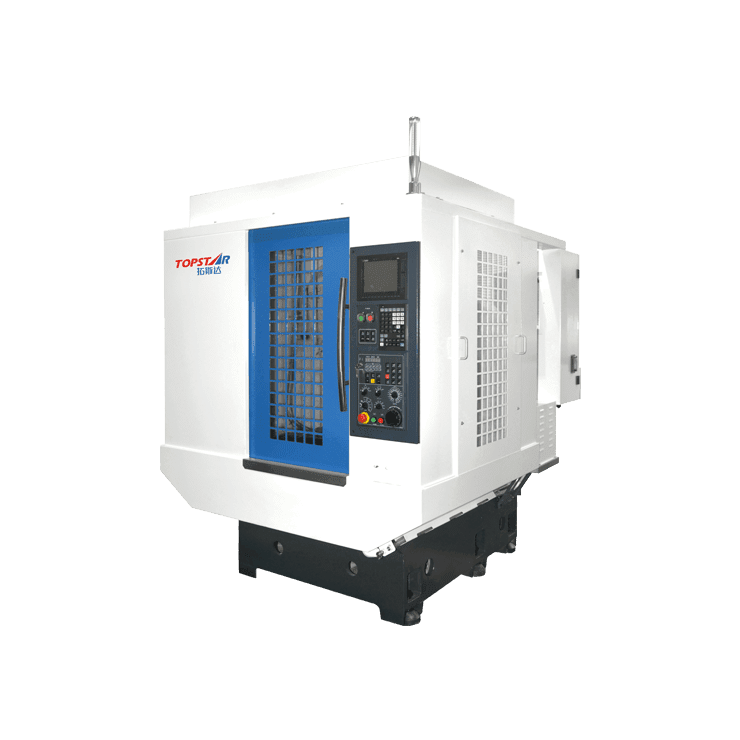

Referring to CNC tools can generally be bulky floor-standing machines. However, the CNC machine is also a suitable desktop option for creative production studios with limited space or small studios.

It is standard on the desk and office, and the closed design is adopted. No need to worry that the debris generated during operation will be sprayed out randomly.

It is more suitable for use in indoor spaces. Debris no longer flew around the room.

What is a Desktop CNC Machine?

The CNC machine tool is a desktop machine tool with the lid closed; after the user puts the material into the machining area, the top can be closed so that the debris can gather inside the body. Machine and is cleaned more easily.

There are desktop CNC lathes, desktop CNC milling machines, and five-axis CNC milling machines, which are mainly common in the production workshops, testing houses of scientific research and development units, and innovation laboratories of the university. University and other small parts machining.

Dimensions of the machine

The body of the desktop CNC machine is also relatively small; the surface size is 850 * 480 * 680mm, and the flat part has a length and width of 750 * 650, so it will not take up too much space on the table suitable for compact purposes.

The development team says that in many cases, CNC machining is more productive than 3D printing and can process metal materials. However, the two are not in a competitive relationship. Instead, they are the best partners. Users can use 3D first.

After the printer does the test and verifies that there are no problems with the design, materials are selected from the experience of test works, and desktop CNC machine methods are common to produce more durable parts.

Conclude

CNC machines are the perfect complement and support to replace the old way of machining. It helps businesses produce and process products more accurately, increase productivity, and reduce product costs.

At TOPSTAR MACHINE, you get the best injection molding machines at the best price.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2022/03/24

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2022/03/24

- Star Case | Topstar helps Santong upgrade its intelligent plant 2022/03/24

- Topstar Special | National Science and Technology Workers Day 2022/03/24

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC