How does Industrial Robot work? Ultimate Guide

2022/03/24 By Topstar

What is an industrial robot?

Using industrial robots in industrial processes provides producers with the necessary competitive advantage with noticeable increases in productivity and the quality of the parts produced, working with repeatability and optimizing productivity rates.

Moreover, the automation of the manufacturing process is the key to guaranteeing your end customers that your company will deliver reference products in a fast way with intuitive visualization and at a very competitive price.

Injection molding robotics in the plastics industry offers several application advantages, including:

- Decreased part variations which in turn reduce waste and increase yields

- Consistent quality of produced parts

- Reduced molding, labor, and finished product costs

- More compact cycle times

- Superior productivity and efficiency

- better flexibility

Three lines of industrial robots are worth investing in today

Robotic plastic injection machine is a type of plastic industry machine appreciated today.

Therefore, to improve the factory’s productivity, many businesses have chosen to apply plastic injection machine robots to the production process. Moreover, companies can choose different robot arm lines depending on specific needs.

Below are three lines of plastic injection molding machine robots with outstanding quality, high-quality materials, and impressive productivity. Industrial robots will undoubtedly be the most investment-worthy products for today’s plastic businesses.

TABLE OF CONTENTS

- GU series plastic injection machine robot

- Specifications

- Outstanding advantages

- GU series plastic injection machine robot

- General information

- Outstanding advantages

- GU series plastic injection machine robot

- General information

- Outstanding advantages

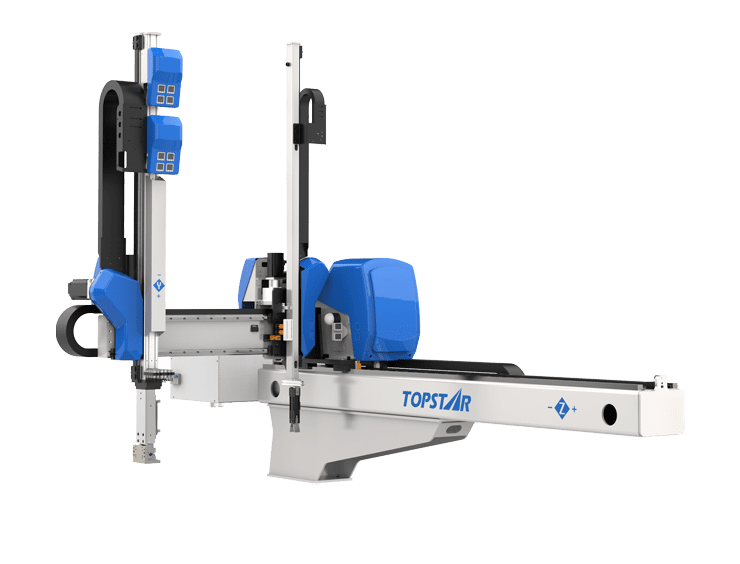

Plastic injection machine robot

A plastic product-picking robot is a machine that specializes in industrial production processes, especially in the plastic industry. Moreover, the robot arm works very flexibly with an intelligent structure. Accordingly, industrial robots will replace human hands to perform stages that require meticulousness and high precision, dedicated to picking up products and stubs.

Outstanding advantages of the GU series of robots

Moreover, the GU series of robots are dedicated to picking up products and cutting the plastic injection molding machine’s excess tail (high tail) into a lying shape.

- The stub-picking robot arm uses high-strength aluminum alloy with precisely textured sliders.

- Optimized design to reduce noise, long life

- A dual cutting arm with a unique design with a belt increases industrial robot speed and shortens up and down time while helping to reduce the pitch of the whole machine.

- Especially suitable for presses from 300 tons or less

- The most cost-effective robotic arm product line for customers

GU series plastic injection machine robot

Applying the GA robot arm to the production process will help businesses improve productivity, save labor costs, and bring a professional and synchronous image to the plastic industry’s production line. Generally speaking.

Moreover, at reputable addresses specializing in selling robotic arms, an industrial robot is also one of the devices that are especially popular with customers, thanks to the following advantages:

Outstanding advantages of robot

GU robot arm is a line of 2 grippers, and one servo with high productivity

- The advantage of the GU robot is that it is cheap, easy to operate, and saves energy

- The machine has high durability, stable performance, extended use time

- The device can grasp both the product and the glued tail

- GU robot is especially suitable for presses 450 tons or less

Plastic injection industrial robot

The robot arm application will help you to have more options on how to drop the product from 2 to 3 positions. Moreover, the device performs many complex operations, and the control and operation processes are also straightforward.

Therefore, if the GU robotic arm is applied to the production process, it will save time and increase efficiency.

General information about the robot

About 3-axis servo robot arm (GU): 3-axis servo horizontal robot arm is often used for plastic injection molding machines from 50 to 550T in the form of lying products and residual tails. 3-axis AC servo of industrial robot motor, precise positioning, fast speed, stable operation, provides excellent performance.

Moreover, the 5-axis servo robot arm (GM5): The 5-axis servo robot arm comprises three main parts: the mechanical part, the controller, and the software, which the control box has four control inputs from the PLC plus four relay outputs to control other devices.

A USB to COM wire to connect the controller to the computer. Indeed, the 5-axis robot arm. Be able to “obey” the commands in the most accurate way.

Outstanding advantages robot

- Accurate positioning, fast speed, and high stability

- Affordable price, easy to operate, high durability

- The industrial robot is made of high-quality steel with a high bearing capacity

- Equipped with an advanced electronic system to help automate the product picking process, saving time to pick up products and increasing productivity effectively.

- Effectively save energy and ensure high safety during use

- Special equipment suitable for presses from 1800 tons or less

Above are the three most appreciated plastic injection machine robot arm lines today. If you want to improve the productivity of your plastic injection factory. Moreover, the application of a robotic arm in the production process is the first solution for you.

With many years of experience in the industry and a team of highly skilled technicians, we will be a prestigious address specializing in providing you with quality industrial robots for the plastic industry, especially the robot line of plastic injection machines.

Modern, durable at the most affordable price

TOPSTAR is a reputable brand specializing in manufacturing and supplying all kinds of machinery in the plastic industry.

With continuous efforts and efforts, we aim to become the leading supplier in Vietnam of plastic machinery and equipment. Moreover, customers can be completely assured of the quality of industrial robots, along with the following:

- The simple and convenient buying process

- Easy and fast payment method

- Prestigious and professional sales policy

Where to buy the best industrial robot from China?

The best place to buy industrial robots is TopStar. We carry a wide range of injection molding machines and industrial robots to help you make your business swift and productive.

TRENDING POSTS

HOT TOPIC

- 3 in 1 Compact Dehumidifying Dryer

- accuracy

- Air Chillers

- all electric injection molding machine

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- molding material Dehumidifying System

- mould temperature controller

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection robot

- Plastic Molding machine

- plastic molding press

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- production of plastic seats

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water distributor

- Water Type MoldTemperature Controller

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC