What is The Working Range of an Industrial Robot Arm?

2022/04/26 By Topstar

The number of axes a robot has is also called degrees of freedom. A simple industrial robot arm is enough if you have simple tasks like picking up and moving apart from one conveyor to another.

However, if your robot has to operate in a small workspace and its arm needs a lot of mobility. A robot with 6 or 7 axes will be the best option. It is worth noting that the presence of a robot with more degrees of freedom than necessary for a specific task. It is an advantage that allows it to be repurposed and used in more studies.

Working range of an industrial robot

When selecting Equipment, it is necessary to consider the maximum distance the robot must reach to complete the tasks. The maximum vertical reach of the industrial robot arm is measured from the lowest point the robot can go to the full height.

The maximum horizontal reach is the distance from the center of the robot’s base to the farthest point the arm can reach horizontally.

Industrial robot: repeatability and accuracy

The ability of a robot to reach the same position every time it performs the same procedure. For example, if your robot is required to create an electronic circuit board. You may need an industrial robot arm with high repeatability and accuracy. If your task is rather rough, such as palletizing, it makes no sense to overpay for increased accuracy.

Speed

As such, there is no single “speed” parameter for robots. Depending on the task, the speed can be linear, angular, expressed in units of repeated actions over some time, and similar values.

Weight

The mass of the robot is an essential factor when designing a robotic cell. If an industrial robot must sit on a unique base or rail, its weight must be known to create appropriate support. Suppose the industrial robot arm supposes to move weights. Moreover, it is necessary to add the maximum weight of the object moves to this value.

Presence of brakes

Each robot manufacturer provides information about the braking system of their robot. Some robots have brakes on all axes, while others do not. You need to have enough brakes to have an accurate and repeatable position in the work area.

Industrial robot: torque and inertia

The manufacturer may specify the inertia of specific arm segments for high-precision applications. Moreover, if your maneuver requires a certain amount of torque to complete the job correctly, you must check if the maximum torque applied to the axle is sufficient.

If the limit torque on the axis exceeds, the industrial robot arm will turn off due to overload.

Industrial robot: protection measures

Depending on the working conditions, the Equipment must meet specific standards of protection against external influences in terms of such parameters as security and safety.

In the descriptions and technical documentation, the degree of protection indicates by the IP code (International Protection Marking – international protective marking, standards for the protection of housings from the penetration of liquid and solid substances inside).

Different Marking Procedures of Industrial Robot Arm

Moreover, the marking has the form IP-XX, where the first X means protection against foreign objects (from parts of the human body to dust particles – from 1 to 6), and the second. Protection against water penetration at different exposure times and pressures (from 1 to 9).

If the robot works with food, laboratory, or medical instruments in flammable or corrosive environments, you will need a device that meets specific industry standards.

Industrial robot arm: application cases

Wood construction, BEC, and ICD

One of the activities of the Institute for Digital Design and Construction at the University of Stuttgart is robotic production in architecture. Moreover, in collaboration with BEC GmbH, ICD has developed an innovative lightweight wooden pavilion that can only be built with the help of robots.

The build process was as follows:

- Robot 1 installs the base on the biaxial positioner;

- Robot 2 applies glue to a wood panel;

- Similarly, Robot 1 attaches a carrier beam to it;

- Robot 2 nails the shaft into place with wooden nails;

- Moreover, industrial robot arm 1 glues the additional panel to the glue applied to the post by robot 2;

- The cover panel also fixes with nails;

- Once the glue has hardened, the robot places the assembled structure back on the DKP-400;

- Furthermore, Robot 2 precisely mills corner contours and joints;

- Robot 1 mounts the resulting part of the structure.

Multi-Purpose Mobile Robots

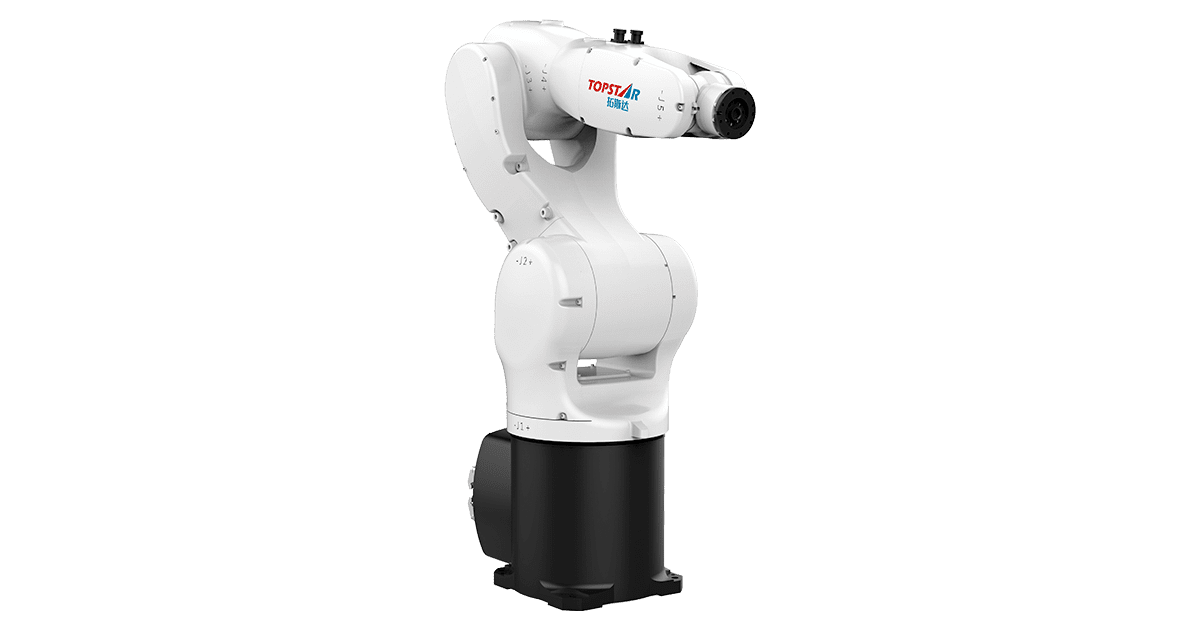

TOPSTAR specializes in the production of special machines with different technologies. In its work, the company uses robotic systems installed on a mobile platform.

The TOPSTAR robotic arm has the highest repeatability and precision and can work efficiently in confined spaces. During operation, a light protective fence is installed around the industrial robot arm for safety reasons.

Moreover, the tilt and height of the table can adjust to maintain the patient’s hemodynamics and provide the physician or surgeon with optimal access to the operating area. This is advantageous in long-term interventions, where the surgeon must wear a heavy lead apron.

Industrial robot: Recommended Equipment

A collaborative robot that, thanks to its modular design, even a schoolboy can assemble. Working with it is as easy as using a smartphone. If desired, the operator can manually move the industrial robot arm to the desired position and let it learn the new movement. This direct learning feature allows even inexperienced operators to get the robot to complete the task.

Moreover, one control unit can control two robots simultaneously, reducing the initial cost. The I/O module and the Ether CAT socket on the robot body make it easy to connect various peripheral devices such as a gripper, optical sensor, etc.

Features of the industrial robot arm

Features of robot arm model:

- Compact dimensions, suitable for equipping even a tiny workplace;

- Ease of installation and maintenance;

- Specialized software developed for this series of manipulators – KR c4 compact;

- Wide scope;

- Ease of installation and maintenance;

- Specialized software;

- High speed of work;

- Degree of protection IP 54.

The manipulator equips with a new-generation recognition system. This is a compact 6-axis robot that can mount on almost any surface, including ceiling or wall. Moreover, the range of the robot is up to 90 cm, and the load capacity is up to 10 kg, with its weight – 54 kg.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2022/04/26

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2022/04/26

- Star Case | Topstar helps Santong upgrade its intelligent plant 2022/04/26

- Topstar Special | National Science and Technology Workers Day 2022/04/26

HOT TOPIC

- .ervo motor-driven linear robots

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 2

- 21

- 23

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 5-axis CNC machine

- 62

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar