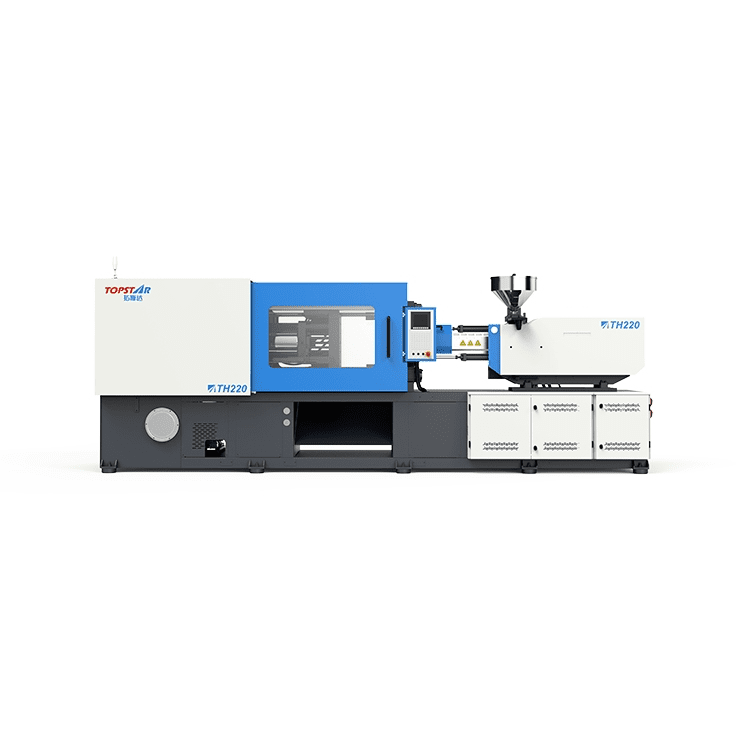

3 Types of Injection Molding Machine Desktop

2021/12/31 By Topstar

What types of plastic injection machines are there?

In recent years, there are many types of injection molding machine desktop on the market. Are you reeling from knowing what kind of plastic injection molding machine? Are you looking for information about popular plastic injection machines in China?

Want to know which company’s plastic injection molding machine is good, trusted by many people? So today we will help you answer this question!

What types of plastic injection molding machines are currently available?

In the mechanical industry, producing plastic molds, plastic injection machines are specialized tools. Not only that, they also apply in many manufacturing industries for the purpose of creating plastic products based on automatic injection and injection mechanisms. There are many ways to classify plastic injection molding machines:

Classification of plastic injection molding machines by transmission method

When classified according to this method, plastic injection molding machines are divided into two categories:

Electric plastic injection machine

This is a machine that uses a Servo motor to adjust, close – open, maintain the clamping force of the mold and push the pin.

Hydraulic plastic injection machine

As a person in the mold manufacturing industry, you will not be unfamiliar with this machine. Moreover, it is one of the most common equipment used by plastic mold factories China. Similarly, this type of machine uses a hydraulic system to open – close and maintain the clamping force of the mold.

Classification of injection molding machine desktop by operating mechanism

When considering the operating mechanism, plastic injection molding machines are divided into two types: automatic and semi-automatic.

Automatic plastic injection machine

As the name suggests, this is the type of device that is 100% capable of operating on its own it starts. When operating injection molding machine desktop, the user will not need any human intervention.

Semi-automatic plastic injection machine

This is a semi-automatic plastic injection molding machine. It is a device that partially self-operates after being started, and partly human-influenced.

Classification of plastic injection machines by mold position

Based on mold position, plastic injection molding machine divides into:

- horizontal injection molding machine,

- vertical injection molding machine

- Moreover, tilting injection molding machine and rotary multi-mode injection molding machine.

Horizontal plastic injection machine

Basically, this is the most common type of plastic injection molding machine. The part of the machine, the mold unit and the nozzle parts come on the central axis and the mold opens in the horizontal direction.

Vertical injection molding machine (vertical press)

As the name suggests, the part of the machine, the mold part and the nozzle parts will be on the center axis vertically, and the mold opens up in the vertical direction.

Tilt injection molding machine

The mold unit and the nozzle parts are not on the central axis, but form an eccentric angle. Injection direction and interface are on the same mold surface.

Multi-rotational injection molding machine

The multi-rotational injection molding machine comes by the clamping rotary device structure, the mold arranged around the rotating shaft.

Classification of plastic injection machines by size

In addition to the types introduced, plastic injection machines divides into large and mini machines in terms of size.

Big size

Generally, large plastic injection molding machines are large size plastic injection machines. This type of injection molding machine desktop will be good in production workshops with a pressing force ranging from 50 to more than 450 tons.

Mini size injection molding machine desktop

Generally, this is the miniature of the large model. There is no difference in the structure and operating principle of these two types of plastic injection molding machines. The most obvious difference between a large plastic injection machine and a mini plastic injection machine is the size and pressing force.

With small size and weak pressure, this machine can only produce products of small size, not too good quality.

An indispensable step in the manufacturing process of plastic products is to press plastic into the plastic mold. It is to fill the mold cavity to create products on the injection machine.

Moreover, the injection molding machine desktop is responsible for supporting and clamping the plastic mold, melting the thermoplastic and injection molding with high pressure in the mold cavity.

How to shape material in injection molding machine desktop?

Then hold the mold to let the molten plastic in the mold cool down and shape the product when the mold is opened, the ejector system will push the plastic product out.

Such cycles continuously repeat for the mass production of plastic products. If you want to produce another product, people will make other molds and put that mold on the injection molding machine to continue the injection molding process.

1. Structure of injection molding machine.

05 basic systems of injection molding machines that operators, maintenance and repair of old injection molding machines need to know when working with the machine:

1- Clamping system

2- Mold system

3-Moreover, spray system

4- Injection molding support system

5- Furthermore, control system.

Injection molding support system has 04 main systems (Injection press support system)

Main parts in injection molding support system

– Body (Frame)

– Hydraulic system (Hydraulic system)

– Moreover, electrical system (Electrical system)

– and Cooling system (Cooling system)

Body

Is the system that links and holds the systems and machine parts together to make the machine operate stably and reliably?

Hydraulic system:

Injection molding machine desktop provides the force to open and close the die generates and maintains the clamping force causing the screw to rotate and move back and forth giving force to the push pin and the sliding of the side core. Similarly, this system includes: pump, valve, motor, pipeline and oil tank..etc

Electrical system

Power supply for the electric motor and thermal control system goes through thermal rings (heater band). Furthermore, it is to ensure stable operation of the whole system through the wiring and control cabinet.

Cooling system of injection molding machine desktop

Provide water or ethyleneglycol solution to cool the mold, hydraulic oil and prevent the raw plastic at the hopper from melting. It is difficult for the upper raw plastic to enter the plastic chamber. The heat exchanger for hydraulic oil is about 90-120 degrees F.

The water temperature controller provides the right amount of heat, pressure, and flow to cool the hot plastic in the mold.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2021/12/31

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2021/12/31

- Star Case | Topstar helps Santong upgrade its intelligent plant 2021/12/31

- Topstar Special | National Science and Technology Workers Day 2021/12/31

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC