Introducing The Picker Injection Robot

2022/11/17 By Topstar

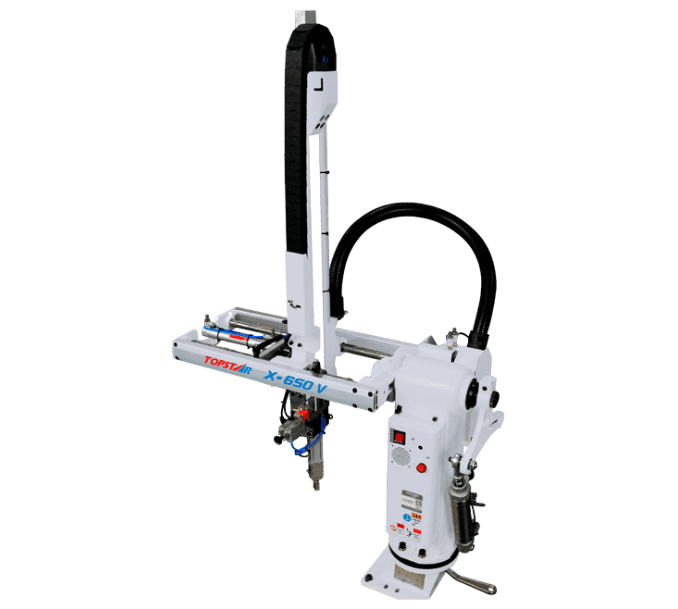

Introducing The Picker Injection Robot

The Picker Injection Robot is a collaborative robot that works seamlessly with your team to pack, sort, and order items in boxes. A simple interface enables your associates to select the correct containers and products to perform the picking process. The Picker Injection Robot’s three-axis motion control and brushless servo drive motors allow precise, high-speed picking and placing tasks, including packing, sorting, and order picking. This means you can get more done in less time. Cooperative robots can work with humans in a shared workspace environment to achieve maximum security.

The Picker Injection Robot is cooperative.

You can have a productive and safe workspace with the Picker Injection Robot. It works with humans in a shared workspace for efficient packaging, sorting, and order-picking operations.

The robot’s lightweight aluminum body is durable and safe for people around it. It has an industrial-grade reduction gearbox allows smooth operation at speeds up to 6 m/min (20 ft/min).

Make your employees’ operation more convenient.

The Picker Injection Robot is a simple interface that enables your associates to select the correct containers and products to perform the picking process. Picks items from an inventory, sorts them into boxes, and orders picking. The weight of the product should be less than 50 pounds.

Three-axis motion control and brushless servo drive motor of Picker Injection robot

The Picker Injection Robot’s three-axis motion control and brushless servo drive motors allow precise, high-speed picking and placing tasks, including packing, sorting, and order picking. This means you can get more done in less time!

Such as:

-Packaging

-Sorting and order Picking (OOP)

The technology behind the robot allows it to operate efficiently by using an onboard computer that controls its actions based on instructions from software or hardware interfaces.

The cooperative robot has good security!

Collaborative robots are designed to work along with humans in a shared workspace environment. This is a safety-conscious approach, as it reduces the risk of injury while increasing productivity and quality. Picker injection robots usually play a role in manufacturing, warehousing, and logistics applications, in which fast and accurate picking is crucial.

It has a lightweight aluminum body that is safe for people around it. With built-in sensors, the robot can work in close contact with people without causing harm or damage to itself or others.

This Injection Robot uses built-in sensors that allow touchless human interaction. This keeps your workers safe without compromising productivity rates or quality standards.

The robot can work alongside humans in a shared workspace environment designed for maximum safety. It is ideal for use in hospitals and workplaces where people constantly interact with sensitive or dangerous machinery.

The robot’s lightweight aluminum body is durable and safe for people around it.

The Picker Injection Robot is made of lightweight aluminum. Because of this, it is highly durable and can withstand a lot of wear and tear.

This is how the body of a robot is designed. Considering the safety of people around the robot, it can protect people from being hurt by the robot itself.

Picker Injection Robot improves order efficiency!

The Picker Injection Robot is an intelligent, collaborative robot that can help you fulfill orders faster.

To provide you with a more seamless experience, It uses built-in sensors that allow for touchless human interaction. This keeps your workers safe without compromising productivity rates or quality standards.

Summarize the Picker Injection Robot

The Picker Injection Robot is a collaborative robot that works seamlessly with your team to pack, sort, and order items in boxes. The Picker Injection Robot’s three-axis motion control and brushless servo drive motors allow precise, high-speed picking and placing tasks, including packing, sorting, and order picking. This means you can get more done in less time.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2022/11/17

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2022/11/17

- Star Case | Topstar helps Santong upgrade its intelligent plant 2022/11/17

- Topstar Special | National Science and Technology Workers Day 2022/11/17

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC