Topstar Scara Robots Help Appliance Manufacturers Improve Efficiency By 30%

2022/03/30 By topstar

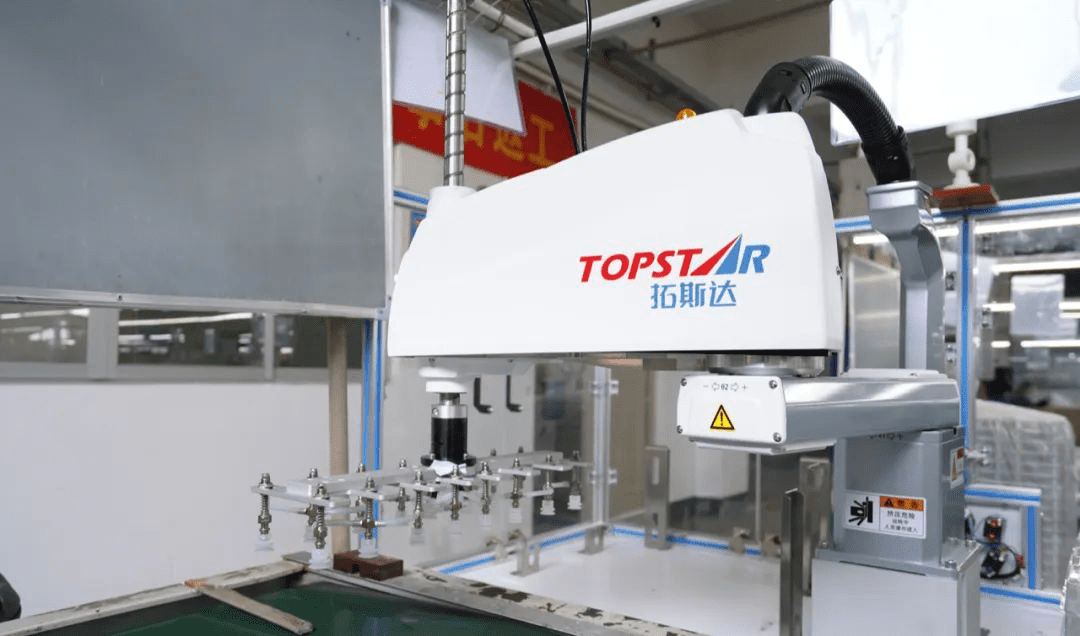

Topstar Scara Robots

Two thousand years ago, the Chinese began to use horsehair and stencils for the initial screen printing, which to a certain extent, contributed to the development of human material civilization. Nowadays, screen printing is closely related to people’s daily life and is also related to almost all industrial products, ranging from routers, and set-top boxes, to sweeping robots; screen printing has long been a vital link for home appliances before they leave the factory.

Guangdong Weir Technology Co., Ltd. (now referred to as “Weir Technology”) is an essential partner of Topstar in the smart home appliance industry. Founded in 1999, Well Technology has nearly 200 engineers and technicians of various types. It provides one-stop services for precision molding, injection molding, secondary processing, and product assembly for innovative home appliance enterprises.

Intelligent appliance industry

The smart home appliance industry is a labor-intensive industry. The changes in the needs of young people have brought about an increase in the total market demand in the industry, which has gradually made Weir Technology feel the pressure of rising labor costs and unstable production capacity. It is particularly urgent to upgrade the automation of enterprise product lines.

Currently, the screen printing process in the home appliance industry is still completed by many workers, relying mainly on experienced workers to carry, load, confirm the position and start the screen printing machine. Workers repeat a single action for a long time and quickly become tired. It affects the quality of products, resulting in increased production costs, and significantly reduces production efficiency. At the same time, the time-consuming, polluting disadvantages of the screen printing line are also subject to criticism.

Topstar automatic screen printing production solution selected the R700-05-Z industrial robot, replacing the traditional manual completion of substrate loading and unloading, fixed-point handling, and other work, successfully helping Weir Technology to achieve the automation of production line upgrade. While reducing labor costs, it is more effective to stabilize production quality and improve production efficiency by more than 30%.

SOLUTION ADVANTAGE

01 Effectively Reduce Labor Costs

n a set-top box screen printing line of Weir Technology, five sets of Topstar R700-05-Z industrial robots have become beautiful scenery. They are orderly and automatically complete a series of work tasks such as gripping, loading and unloading, workpiece handling, etc., and cooperate with the screen printing machine to print different colors and patterns. A SCARA industrial robot replaces a worker, frees the operator from the single high-intensity work, and helps customers effectively reduce labor costs.

02 Significantly Improved Screen Printing Efficiency

Savvy home appliance market consumers pursue high quality of life, so smart home appliances with rich functions and fashionable appearance put higher requirements on the production process equipment.

In the solution, this Topstar R700-05-Z industrial robot can ensure a stable and efficient operation for a long time, meeting the smooth and fast operation requirements of home appliances’ screen printing production line. In addition, this SCARA robot has a complete repeat positioning accuracy of ±0.025mm, a rated load of 5kg, and accurate pick and place. Compared with manual operation, it increases production efficiency by more than 30% and significantly improves product quality.

03 Significant Improvement In Ease Of Operation

Topstar automatic screen printing solutions do not change the customer site or redeploy the production line. An essential start of the quick operation mode can protect the front-line staff from quickly changing production, significantly improving the solution’s ease of operation. During the screen printing process, the industrial robot and screen printing machine signals are interlocked, ensuring that the entire process is carried out smoothly and safely.

CUSTOMER WORD OF MOUTH

After the introduction of Topstar automatic screen printing solution, Weir Technology screen printing line automation, production efficiency increased by more than 30%; the screen printing process is more accurate and fast. Weir Technology Chairman Ning Jianqiang said that after the automation upgrade, production efficiency dramatically improved, labor costs and energy consumption was reduced, and quality control whad effectively guaranteed.

From the injection molding auxiliary machine to robot, from robot to automation workshop integration transformation, ten years of cooperation is the Weir Technology to Topstar products, technology, and services of affirmation and trust. Ning Jianqiang hopes that in the future can continue to work together with Topstar to provide professional and efficient solutions for intelligent home appliance industry enterprises.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2022/03/30

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2022/03/30

- Star Case | Topstar helps Santong upgrade its intelligent plant 2022/03/30

- Topstar Special | National Science and Technology Workers Day 2022/03/30

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC