Topstar’s advantages as an injection molding machine brand

2024/01/19 By Topstar

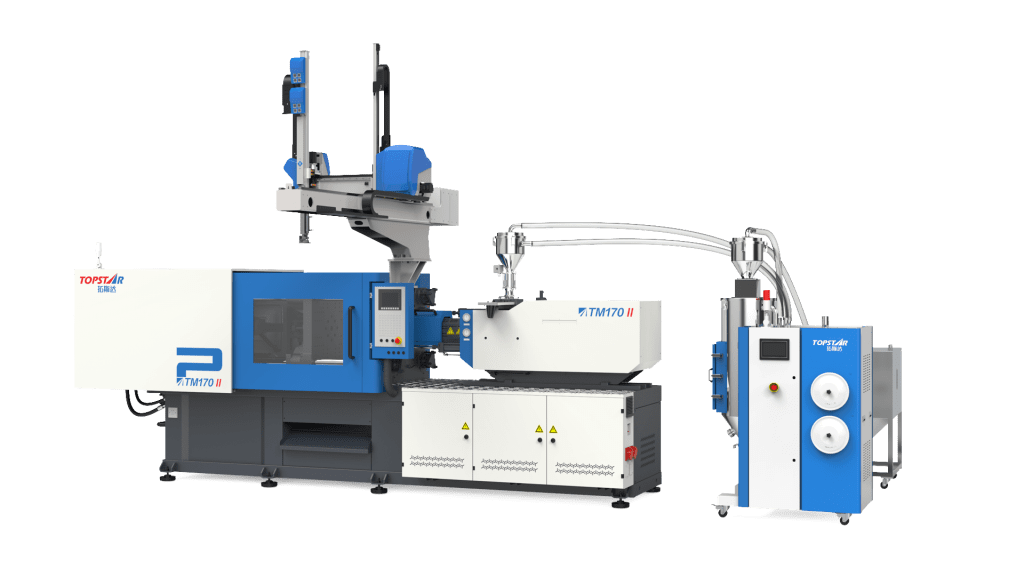

Topstar is an injection molding machine brand from China. It uses industrial robots, injection molding machines, and CNC as its core intelligent equipment and its three-core controller, servo drive, and vision system technologies. Create a smart hardware platform driven by core technology to provide innovative factory solutions for manufacturing companies.

Intelligent injection molding machine brand

With the arrival of Industry 4.0, manufacturing factories in China and worldwide are gradually implementing intelligence to reduce labor costs. Topstar’s intelligent whole plant includes a one-stop module planning and construction: injection molding machine + auxiliary equipment, front-end automated central feeding, back-end robot automation module, water, electricity, and energy module, and data management MES module to achieve intelligent injection molding. Factory modular planning makes manufacturing more accessible. An innovative manufacturing service platform that realizes the integration of factory planning + injection molding, automated production line + data management.

Injection molding machine equipment intelligence

Topstar’s complete injection molding equipment includes machines, robots, and auxiliary equipment. We have integrated an industrial Internet of Things platform and self-developed servo, control, and vision systems that align with industry processes. We have functions such as high-response pressure closed-loop control, multi-pump closing/diverting hydraulic control, and functional safety. It is the best choice for the power drive of injection molding machines. The control platform integrates with the injection molding machine controller, enhancing collaboration and efficiency between the machine and the robot.

Provide solutions for different automation industries

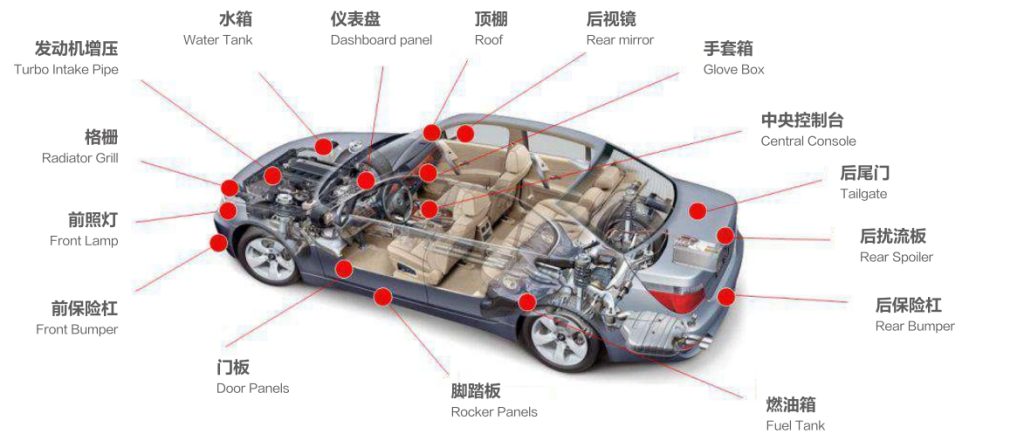

As an intelligent injection molding machine brand, it not only realizes intelligence in injection molding production but also provides automation application system business, providing manufacturing companies with professional automation solutions to help them quickly become intelligent and implement large-scale industrial production of new technologies. For example, we have over 100 patented technologies in automobile auto parts, covering 13 processes, including welding, cladding, spraying, and assembly. We provide car door panel welding and Dongfeng Honda armrest gluing line solutions. It maintains technological leadership in lithium battery manufacturing, assembly, and assembly equipment and has obtained over 100 national patents. It has also established strategic partnerships with well-known battery companies such as ATLCATL and BYD. Our products have been exported to the United States, India, and other countries and regions.

Customer service process

Unlike traditional equipment suppliers focusing on product sales and quality control, Topstar develops products, provides high-quality after-sales services, and implements the core value of “serving customers wholeheartedly.” We have service outlets worldwide to respond to customer needs quickly, collect customers’ on-site information and record faults, give rational maintenance suggestions, and help customers adjust their equipment to the best condition as soon as possible.

overseas influence

Topstar is actively developing its presence in the global market. As of June 30, 2023, it has approximately 30 domestic offices. Topstar (Vietnam) Technology Co., Ltd. has been established, and it is increasing efforts to develop its business in Mexico and enhance its competitiveness in overseas markets. In February 2023, Topstar will participate in the five-day PlastIndia (India International Plastics Exhibition) and work with local partners to bring new high-quality electric injection molding machines and supporting auxiliary equipment based on India’s market demand and industry development. Presented at this exhibition. Last year, we appeared at the plastics industry exhibitions in Vietnam and Turkey. Therefore, we will continue to bring competitive technology solutions to the global market.

Injection molding machine brands for the future

In the future, we will continue to gradually help manufacturing companies realize smart factories to save workforce, increase efficiency, and reduce costs to achieve stable quality, minimum cost, and flexible delivery. This allows automation companies worldwide to achieve system breakthroughs, system planning, and single-point breakthroughs. Help 1 million manufacturing companies achieve intelligent manufacturing.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/01/19

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/01/19

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/01/19

- Topstar Special | National Science and Technology Workers Day 2024/01/19

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC