Injection molding machines can be divided into large and small-size injection molding machines according to size. These two sizes are suitable for injection molding of different products, and their injection molding processes are also different. Therefore, the right size is crucial to obtain the product during manufacturing. Whether you produce small or large components, choosing the right machine size can significantly impact efficiency and quality. In this guide, we take you through the factors to consider when sizing your injection molding machine based on your needs.

Features of Large Size Injection Molding Machine

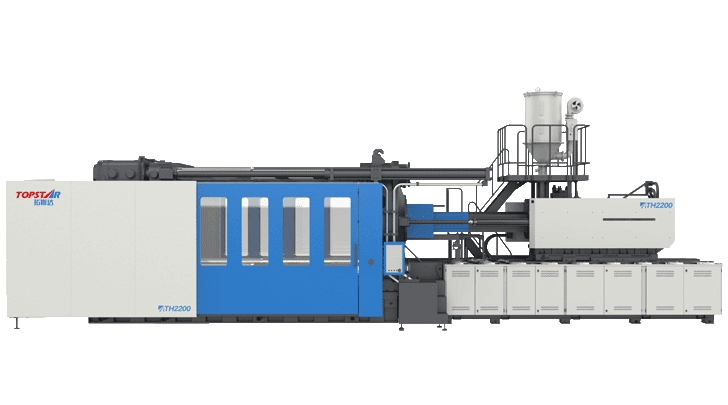

Large-size injection molding machines are equipment specifically used to produce large plastic parts in the manufacturing industry and are suitable for handling large-scale injection molding projects. Large-size injection molding machines are equipped with high-tonnage (generally 2200T) mold clamping devices, which can exert a large force to keep the mold closed during the injection process. This allows them to fit into large, heavy molds required to produce large plastic parts. These machines also feature wide platens or mold mounting surfaces, ensuring stable and even clamping force distribution across the entire mold. They can accommodate large molds and provide ample space for producing large parts.

Meanwhile, large-size injection molding machines efficiently fill large molds with molten plastic. These machines are equipped with high-capacity injection devices capable of delivering large amounts of material under high pressure. Structurally, they can withstand the intense forces and pressures generated when molding large parts, ensuring durability, stability, and reliable performance over long periods of operation.

Features of small-size injection molding machines

Small-size injection molding machines are also ubiquitous in the manufacturing industry. They are mainly multi-functional tools for producing small and medium-sized plastic parts and assemblies. Their small footprint makes them suitable for small workshops with limited space. These machines typically have lower clamping forces (generally between 90T-470T) than their larger counterparts, making them ideal for molding small, delicate parts at lower injection pressures.

The injection device of a small injection molding machine provides a small injection volume of molten plastic material. This allows precise control of the amount of material injected into the mold cavity, ensuring the molding of small plastic products. Manufacturers optimize them for fast cycle times, enabling them to produce small parts at high speeds with short cooling and ejection times. This increases productivity and throughput.

What different products are suitable for production?

Large and small injection molding machines are suitable for producing different types of products based on their respective characteristics and capabilities. Large-size injection molding is often used to make automotive parts such as bumpers, instrument panels, and interior trim panels. It can also produce plastic casing parts commonly required for large household appliances such as refrigerators, washing machines, and dishwashers and large plastic parts used in furniture, such as chair frames, table legs, and cabinet panels.

Small injection molding machines are very suitable for producing small plastic parts. This includes connectors, housings, brackets, and switches for consumer electronics, computers, and telecommunications equipment. Also included are those used in the production of medical devices and equipment. Includes syringe barrels, surgical instrument handles, medical tubing, and small plastic parts used in consumer products such as toys, sporting goods, household goods, and packaging.

Energy Efficiency of Large and Small Injection Molding Machines

Energy efficiency is a crucial difference between large and small-size injection molding machines. Large-size injection molding machines often use hydraulic systems with variable frequency drives (VFD) and servo motors. These systems adjust pump speed and motor output based on actual demand, reducing Energy consumption during idle and low-load periods. Some large-size injection molding machines also have energy recovery systems that capture and reuse hydraulic energy during the deceleration phase of machine operation. The system stores and reuses the recovered energy to power other machine functions, reducing energy consumption.

Small-size injection molding machines usually use all-electric drive systems, eliminating the need for hydraulic systems and reducing energy consumption. Electric servo motors precisely control machine functions, minimizing energy losses and optimizing efficiency. They also use an efficient electric heating system to melt the plastic material and inject it into the mold, allowing precise temperature control and rapid heating capabilities to reduce energy consumption and cycle times.

Differences in life cycle maintenance costs

The life cycle maintenance costs of large and small-size injection molding machines vary significantly due to differences in machine complexity, operating conditions, and maintenance requirements. Large-size injection molding machines typically require higher upfront investments due to their larger size, higher clamping forces, and more complex hydraulic or hybrid drive systems. They have complex mechanical and electrical components that require regular inspection and lubrication to ensure optimal performance. Over time, larger machines’ more prominent size and higher operating pressures can lead to more significant wear and tear on machine components. This can result in more frequent replacement of worn parts such as screws, barrels, and seals and thus increased maintenance costs.

Small-format injection molding machines typically have lower upfront costs due to their smaller dimensions, lower clamping forces, and simpler electric drive systems. This makes them more accessible to small businesses and startups with limited capital budgets. They have fewer mechanical and hydraulic components, simplifying maintenance procedures and reducing labor requirements. Routine maintenance tasks such as cleaning, lubricating, and replacing parts may be more manageable, reducing wear and tear.

Choose according to your situation

Large-size injection molding machines are your first choice for manufacturers who want to produce auto parts, large household appliances, and large plastic parts. Small-size injection molding machines are your best choice for manufacturers of small plastic parts, medical devices, and small plastic parts for household products.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2024/03/18

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2024/03/18

- Star Case | Topstar helps Santong upgrade its intelligent plant 2024/03/18

- Topstar Special | National Science and Technology Workers Day 2024/03/18

HOT TOPIC

- .ervo motor-driven linear robots

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 5-axis CNC machine

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC