What is the working principle of factory drying and dehumidifying equipment?

2023/02/27 By Topstar

Working principle of drying and dehumidifying equipment in the plant

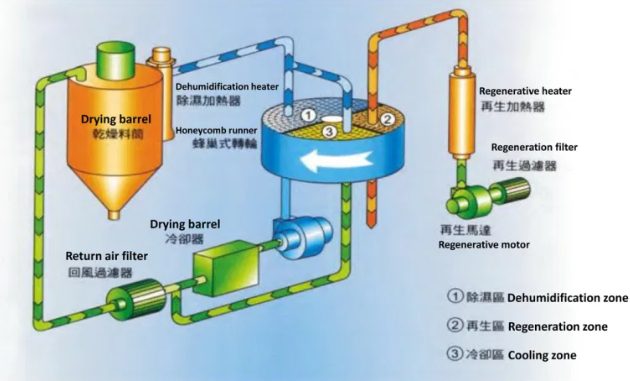

The water vapor from desiccant dryers is compressed and heated as it passes through the machine. The hot compressed air is then passed over a condenser coil, which is cooled down and condensed back into a liquid state, which can then be collected into a tank or piped to other processes. The equipment used in drying and dehumidifying processes is called desiccants or adsorbents.

Desiccant dryer

The water vapor from desiccant dryers is compressed and heated as it passes through the machine.

Water vapor is then passed through a heat exchanger, which is cooled by air flowing over the metal plates of this device.

The condensed liquid then flows back into your plant’s drain system or downspout to be reused on-site for irrigation, such as watering plants or cleaning machinery (depending on how much water was removed from your facility).

The hot compressed air then passes through the condenser coil

Condensation is the process of changing a gas into a liquid. Condensation occurs when water vapor cools down, becomes liquid, and falls to earth like rain or snow.

The hot compressed air is then passed over a condenser coil, cooled down, and condensed back into a liquid state, which can then be collected into a tank or piped to other processes.

Desiccant or adsorbent

The equipment used in drying and dehumidifying processes is called desiccants or adsorbents.

A sorbent is a material that attracts and holds onto certain substances or mixtures. At the same time, others do not show any tendency toward adsorption. The materials that are used as adsorbents are called adsorbents or sorbents.

Material adsorption

In adsorption, a solid surface attracts and holds onto certain substances or mixtures. The attraction is usually caused by chemical bonds between the substance to be adsorbed and the surface of the solid. Adsorption is an example of physical chemistry involving non-covalent bonds. It has potential applications in many industrial processes, including separation, purification, catalysis, and biological imaging.

The word “adsorb” comes from the Latin meaning “to adhere to.”

The materials that are used as adsorbents are called adsorbents or sorbents.

Adsorbents are materials that attract and hold onto certain substances or mixtures, while others do not show any tendency toward adsorption. Adsorbents can be used to remove impurities from a liquid or gas by absorption and purify air and water by removing odors and other contaminants. They are also used in many chemical processes, including distillation and absorption.

Adsorbents are commonly used to produce carbon dioxide gas and other chemicals and can be natural or synthetic.

Adsorption is an endothermic process.

Drying is a process of removing moisture from the air by using heat or chemicals. Adsorption is an endothermic process that requires heat to take place. The heat needed for adsorption can come from the perspective of a heat source, such as solar energy.

When you use adsorption to remove moisture from the air, it helps to improve the quality of indoor air. This process removes water from your home and helps prevent mold growth.

Role of desiccant

Desiccants remove moisture from systems such as refrigerated slurry pipelines, cooling coils, boilers, and condensers.

They are also used to remove moisture from air streams. In this case, they can be referred to as adsorbents or sorbents, depending on whether they are used for drying or dehumidifying purposes.

To make a long story short, drying and dehumidifying equipment is integral to many industrial processes. It is used in food processing, pharmaceuticals, pulp & paper, etc.

TRENDING POSTS

- What factors can cause delays in the injection molding process of plastic molding machine? 2023/02/27

- Exhibition Review| Topstar participates in InterPlas Thailand 2024 2023/02/27

- Star Case | Topstar helps Santong upgrade its intelligent plant 2023/02/27

- Topstar Special | National Science and Technology Workers Day 2023/02/27

HOT TOPIC

- .ervo motor-driven linear robots

- 1.0 guangdong topstar technology co. ltd

- 1.0 topstar china

- 1.0 topstar robot

- 11

- 2

- 21

- 23

- 3 axis robot

- 3 axis robots

- 3 in 1 Compact Dehumidifying Dryer

- 3-axis robot

- 3-axis robots

- 39

- 41

- 5-axis CNC machine

- 62

- accuracy

- Air Chillers

- all electric injection molding machine

- all electric injection molding machines

- All-electric injection molding machines

- and overall production quality. Therefore

- AP-RubberPlas

- automated injection molding machine

- Automation changed engineering

- automation of injection molding robots

- auxiliary machine

- Bench Injection Molding Machine

- Cabinet dryer manufacturers

- Cabinet dryers

- chiller

- CNC Drilling Machine

- CNC Drilling Machines

- cnc engraving machine manufacturer

- cnc laser cutting machine manufacturer

- CNC machine

- CNC Machine Center

- CNC Machine for Sale

- CNC Machine Manufacturing

- CNC Machine Tool

- CNC machine tool product

- CNC Machining Center

- CNC wood carving machine

- Cooling system

- Cross-Walking Single Axis Servo Cylinder Robot

- Cross-Walking Single-Axis Servo Cylinder Robot

- Cross-Walking Three-Axis/Five-Axis Servo Driven Robot

- cross-walking three-axis/five-axis servo-driven robot

- Dehumidifier Dryer

- Dehumidifying Dryer

- delta parallel robot

- Desktop Injection Molding Machine

- Desktop injection molding machines

- Desktop Molding Machine

- desktop plastic injection machine

- Desktop Plastic Injection Molding Machine

- direct clamp injection molding machine

- Direct clamp injection molding machines

- Dosing & mixing system

- Drilling Centers

- Drying and dehumidification system

- drying and dehumidifying equipment

- Drying and Dehumidifying System

- drying system

- effective and efficient. Cabinet dryers are also used in other industries where large quantities of material need to be dried

- efficient injection molding machine

- elbow hydraulic injection molding machines

- electric injection molding machine

- electric injection molding machines

- energy-efficient injection molding robot

- energy-saving injection molding machine

- etc. Among injection molding robots

- exhibition

- features of CNC machine

- Feeding And Conveying System

- Five Axis Machine Center

- Fully automatic injection molding machine

- Gathering Topstar

- giant injection molding machine

- GMU-600 5-Axis Machining Center

- Granulating & Recycling System

- Heavy duty injection molding machine

- High-precision electric molding machines

- high-precision plastic molding machines

- high-speed all electric injection molding machine

- Honeycomb rotor dehumidifier

- horizontal injection molding machine

- Horizontal Injection Molding Machines

- Horizontal Injection Moulding Machine

- Horizontal Mixer manufacturer

- How The CNC Machine Works

- hybrid injection molding machine

- hydraulic injection molding machine

- Hydraulic Injection Molding Machines

- in this article

- Industrial robot

- Industrial Robot Chinese brand

- industrial robot parts

- industrial robot supplier

- Industrial robots

- Industry Chain

- Injection Manipulator

- injection manipulator robot

- injection mold machines

- Injection molding

- Injection molding automation

- Injection Molding Automation Solution

- injection molding dryer

- Injection molding equipment

- injection molding hopper dryer

- Injection molding machine

- injection molding machine brand

- Injection Molding Machine Factory

- Injection Molding Machine Manufacture

- Injection molding machine manufacturer

- injection molding machine manufacturers

- Injection molding machine procurement

- injection molding machine robotic arm

- injection molding machine with a robot

- Injection molding machines

- injection molding material dehumidifying

- injection molding plant

- Injection Molding Robot

- injection molding robot arm

- Injection molding robot automation

- Injection molding robotic arm

- injection molding robots

- Injection moulding machine

- Injection Moulding Robots

- Injection Robot

- Injection robot arm

- Injection robot manufacturer

- Injection robot wholesale

- injection robots

- intelligent injection molding machines

- Introducing Injection Robot

- It is the best choice for drying large quantities of material at once. Cabinetmakers use these machines because they are fast

- large injection molding machine

- large injection molding machines

- Learn what industrial automation and robotics is

- linear robot

- linear robots

- low speed sound-proof granulator

- machine plastic molding

- make sure to add some! Improvements (2) Keyphrase in introduction: Your keyphrase or its synonyms appear in the first paragraph of the copy

- manipulator machine

- manufacturing

- medical grade injection molding machines

- medical injection molding machine

- medical injection molding machines

- micro injection molding machine

- middle speed granulator

- Mini CNC machine manufacturers.

- Mold Temperature Control System

- mold temperature controller

- mold temperature controllers

- molding material Dehumidifying System

- mould temperature control system

- mould temperature controller

- mould temperature controllers

- New electric injection molding machine

- nitrogen dryer manufacturer

- nitrogen dryer system manufacturer

- Oil type mold temperature controller

- Oil type mold temperature controllers

- open day

- Outbound links: No outbound links appear in this page. Add some! Images: No images appear on this page. Add some! Internal links: No internal links appear in this page

- PET Preform injection molding

- phone case maker machine

- phone case making machine

- plastic bottle making machine

- plastic bottle manufacturing

- plastic bucket making machine

- plastic bucket manufacturing

- Plastic chair making machine

- plastic forming equipment

- plastic hopper dryer

- plastic injection machine

- plastic injection machines

- plastic injection molding

- Plastic injection molding equipment

- Plastic injection molding machine

- Plastic Injection Molding Machines

- plastic injection moulding machine

- plastic injection robot

- Plastic Molding machine

- Plastic Molding Machines

- plastic molding press

- plastic moulding machine

- plastic phone case making machine

- plastic-molding machine

- powerful granulator

- Powerful Type Sound-Proof Granulator

- precision injection molding

- precision injection molding machines

- production of plastic seats

- pure water mould temperature controller

- Robot injection molding

- robot injection molding machine

- robot manufacturing companies

- Robotic arm for injection molding machine

- robotic injection molding machines

- robotics in injection molding

- SCARA robot

- SCARA robots

- Service-oriented manufacturing

- Servo Cylinder Robot

- servo driven robot

- Servo Driven Robots

- servo injection robots

- servo motor-driven linear robots

- servo-driven 3-axis robot

- Servo-Driven Robot

- Setup of injection machine

- Silicone Injection Molding Machine

- six-axis industrial robot

- Stainless Hopper Dryer

- Stainless Hopper Dryers

- star club

- swing arm robot

- take-out robots

- the choice between servo-driven robots and hydraulic robots will have a certain impact on efficiency

- the most popular injection molding machine

- the type of injection molding robot

- toggle clamp injection molding machine

- Toggle Hydraulic Injection Molding Machines

- toggle injection molding machine

- Top 10 brands of injection robots

- Topstar

- Topstar Engineering

- Topstar Industrial Robots

- Topstar injection molding intelligent

- Topstar Scara Robots

- Useful Injection molding machine

- Vertical machining centers

- volumetric type blender

- water chiller

- water chillers

- water distributor

- water type mold temperature controller

- Water Type MoldTemperature Controller

- Water-Type Mould Temperature Controllers

- We often face choices when performing injection molding. We will choose the type of injection molding machine

- wholesale of injection molding machines

- x carve CNC

- 热门查询 点击次数 展示 排名 topstar